-

Equipments

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Or Contact Info

-

Coating

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Adhesives

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Agrochemistry

-

-

Agrochemistry

- Emulsifiable Concentrate

- Suspension Concentrate

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Battery

-

-

Battery

- Battery Slurries

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Cosmetic

-

-

Cosmetic

- Lipstick

- Eyebrow Pencil

- Ointment

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

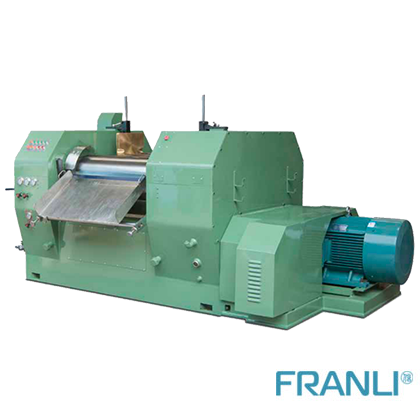

Three Roll Mill

-

TRS-Three Roll Mill For Lipstick

TRS Three roll mill is widely used in milling paste material including paint, inks, China ink, pigme...

-

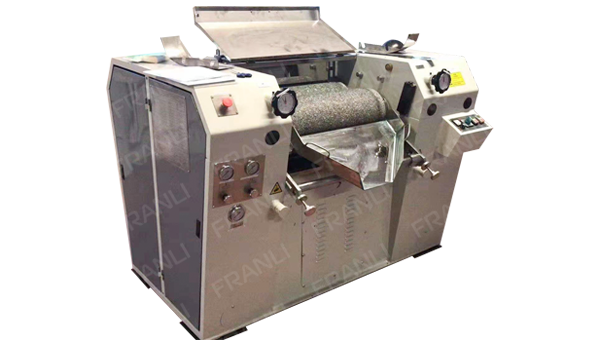

Triple Roll Mill

A triple roll mill consists of 3 horizontally arranged rolls rotating in the opposite direction and ...

-

3 roll mill

3 Roll Mill is a great tool that is used to mix, refine, and disperse any material through three hor...

-

Heating three roll mill

Heating three roll mill is a common type of three-roll mill, mainly used in the grinding of high-vis...

-

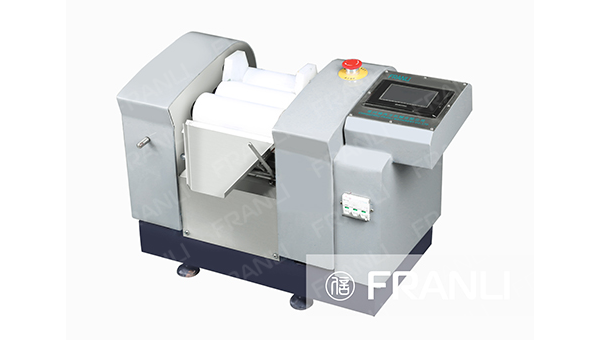

Digital Control Three Roll Mill

The roller of the digital control three roll mill is made of zirconia ceramic material and equipped ...

-

Triple roller mill

Three-roller mills are also called triple roller mills. In daily work, they can be divided into Lab ...

-

Ointment Mill

The ointment mill is also called Lab three roll mill. It is mainly used for the fine grinding of hig...

-

Manual 3 Roll Mill

manual three roll mill is widely used in milling paste material including paint, inks, China ink, pi...

-

Lab Three Roller Mill

FLE Lab three roll mill machine also has a safety system. Such as hopper with handguard, drip tray w...

-

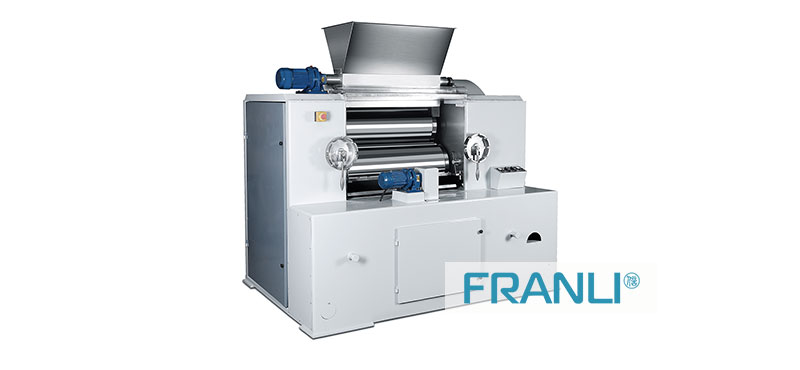

Hydraulic Three Roll Mill

FLE Hydraulic three roll mill has a unique Hydraulic system, which controls pressure roller, dischar...

-

Three roll mill

Three roll mills are widely used in a variety of chemical industries, from medium to high viscosity ...

Three roll mills ![]() are widely used in a variety of chemical industries, from medium to high viscosity productions. FLE machine can break open all kinds of pigment, UV ink, offset ink, decorative paints, and Lubricants, it also can catch the greatest fineness in cosmetics/ lipstick and electronics industries.

are widely used in a variety of chemical industries, from medium to high viscosity productions. FLE machine can break open all kinds of pigment, UV ink, offset ink, decorative paints, and Lubricants, it also can catch the greatest fineness in cosmetics/ lipstick and electronics industries.

Three roller mill, with easy operating and safe cleaning. FLE nowadays has a different model of manual Triple Roller Mill, Hydraulic type, and Lab type. They have their advantages and features to meet different requirements.

We have different series of Three Roll Mill.

TRS &TRM Manual type

Three Roll Mill, their gap of the roller is controlled by adjustable wheels. TRS&TRM three roller mill is an updated type based on S triple roll.

1-TRS&TRM machine transfer gears that soak in oil (oil box). Keeping longer life of the operation, less noise.

2- Cooling control system: TRS&TRM three roller machine installed thermometer, easily check material temp. Three rolls are normally connected with Chiller.

3- normally Reach 10-20um by first passing grinding

While S three roller mill, transfer gears with Grease, cant check chain well. But it is still widely used in Soap, printing industries.

Hydraulic TRH type

Hydraulic Three Roll Mill, which is a full hydraulic auto-controlling system equipment.

1- Cooling system: an individual cooling system for each roller.

2- hydraulic control: hydraulic control pressure blades, roller gaps, etc.

3- Optional installation:PLC system with SIEMENS touching screen, FLE engineer set formulas of grinding according to different viscosity materials.

Lab TRL Type

Lab three roll mill with PLC Touching Screen,which is widely used in medicine, ink, cosmetics, and electronics industries. Small size, digital number auto-operation. Which smarter, safer, and faster. Which is customized for different material requirements,

Vertical type for Grinding Powder

Also, we have a vertical three-roll mill for grinding powder and chocolate. We have 3 rollers, 4 rollers, and even 5 rollers, which are all vertical types. We export to the soap industry and chocolate companies.

Heating type

FLE also offers a heating hydraulic three roll mill for rubber, EVA, PVS, and color masterbatch. As this type of machine grinds high viscosity material, we specially design the gear quality. This type is been Heated by oil or steam.

FLE three roll mill machine are full automatic PLC controlling, hydraulic system, stable operation, reliable quality. We choose the international brand parts. Standrad parts, ABB VFD, Siemens Motor, SKF or NSK bearings, SEW or Nord reducer. A roller is 45-55mm thickness of metal, cast steel. You can widely choose ceramic, alloy, granite rollers for your material. If you have several formulas of material, we can set up formulas in the PLC system, your workers only need to choose numbers on touching the screen, don't need to waste time to adjust the rollers’ gap or the pressure of the blade.

About the feeding system, we have several kinds for different viscosity of the material. Such as a feeding pressure machine, also called an extruder machine. And feeding system is installed on the top with a single reducer motor. While if your material is a crazy high viscosity, and small batch production, we suggest that it’s better to feed material into rollers by manual scrapper.

Our package is a standard export wooden case, and our factory is close by shanghai port, fast delivery, and cheaper shipment. Welcome to connect with us. we will choose a suitable three roll mill for your material. Of course, you are welcomed to send us your material for the first trial before offering an order.

Production Line

-

PCB INK Machine line

FLE supplies all equipments for the production of PCB inks, from the powder feeding station to the filling part.

-

Offset Ink, UV Ink machine line

The FLE engineering company, offer the full set of UV INK Production Line, we can make the full drawing according with your factory size, fo...

-

Offset Ink machine line

FLE is specialized in offset ink full line production for 20+ years. Helped customer save the cost, save the man power, also save the space....

Equipments

News

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

Bead Mill

- SMP Agitator bead mill

- Zirconia beads for sale|Zirconia beads price

- Wet Bead Mill|Bead Mill For Sale

- Sand Mill Machine|Sand Mill For Paint

- Sand Mill|Wet Grinding Equipment Manufacturer

- Bead Mill Machine

- Vertical sand mill

- Bead mill for paint

- Horizontal sand mill

- Turbine bead mill

- Lab bead mill

- Nano Mill

- Vertical Bead Mill

- Bag Filter

- Zirconia Beads

- Pearl Mill

- Dyno mills

- Horizontal Bead Mill

- Agitator bead mill

- Sand Mill

-

Three Roll Mill

-

Twin Shaft Disperser

-

High Speed Disperser

-

Basket Mill

-

High Shear Mixer

-

Double Planetary Mixer

-

Chemical Reactor

-

Kneader

-

Filling Machine

-

Multi-Shaft Mixer

-

Attritor Mill

-

Ribbon Blender

-

Pneumatic Mixer

-

Static Mixer

-

Nitrogen Generator

-

Production Line

- Tricks About Ointment Mill You Wish You ...

- A deep insight into Sand Mill Machine

- What is the difference between dyno mill...

- How To Choose Vertical Bead Mill or Hori...

- What is a three roll mill machine?

- Specification of high speed disperser an...

- Three Roll Mills: Their mechanism, advan...

- high speed disperser machine application

- Faults and Trouble Shooting Methods of H...

- How to operate High-Speed Disperser