-

Equipments

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Or Contact Info

-

Coating

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Adhesives

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Agrochemistry

-

-

Agrochemistry

- Emulsifiable Concentrate

- Suspension Concentrate

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Battery

-

-

Battery

- Battery Slurries

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Cosmetic

-

-

Cosmetic

- Lipstick

- Eyebrow Pencil

- Ointment

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Manual 3 Roll Mill

FLE manual three roll mill are widely sold all over the world, how about our manual three roll mill? Where we already sold out?

FLE manual three roll mill are widely sold all over the world, how about our manual three roll mill? Where we already sold out?

manual three roll mill ![]() is widely used in milling paste material including paint, inks, China ink, pigment, coatings, food, cosmetics, and so on. (Not applicable for roller corrosion material). It is also used in cable material, artificial plastics, soap, and pencil core material. It becomes the key equipment for those industries.

is widely used in milling paste material including paint, inks, China ink, pigment, coatings, food, cosmetics, and so on. (Not applicable for roller corrosion material). It is also used in cable material, artificial plastics, soap, and pencil core material. It becomes the key equipment for those industries.

The roller material is made up of cold hard alloy centrifugal casting. The cold hard alloy thickness is between 15 and 25mm, hardness is between HS 68-75. The roller is grinding on a convex grinder, the effective working surface is a bit convex. During the milling process, because of hard roller and thermal expansion and contraction, it can compensate automatically to improve machine life, also improve the material accuracy and efficiency. For normal material, as its original fineness and hardness, it can be milled once, twice, and even more, times till it reaches requirement(Normally between 3 and 18 microns as gauge measured)

The machine is improved based on the same machine both in domestic and overseas markets and end-user production practice. It’s made up of good quality steel sheet welding to have nice looking, easy operation, lower labor strength, higher machine strength, and longer life.

The machine is equipped with the latest chain transmission technology in the international market. The gear is dipped inside lubricating oil to extend the machine life to the max. extent. It also reduces noise and energy consumption. The gasket part is imported. S series manual three roll mill is equipped with top adjusting roller structure, while SG series manual three roll mill is equipped with gear adjusting structure, easier and convenient and more stable operation. The water temperature display is available at both inlet and outlet to make sure the material temperature keep stable and good quality available. Cooling water recycling device or roller heating device are available as customer request. The material outlet hopper is made up of stainless steel. The machine is coated with solvent resistance paint to keep gloss.

Working theory

The gap between fast, middle, and slow roller can be adjusted as customer products accuracy requirement, and then start the machine, feed the material between two copper blade and middle and slow roller. The material can be transferred to a fast roller after squeezed and rubbed between the middle and slow roller. The outlet blade which sticks tightly to the fast roller surface will collect the products and flow to the products tank via the outlet plate to form a milling cycling.

We are focus on the grade of manual three roll mill gears, and the belt, also the motors. While if needs working smooth, no noise, and stable no moving, we have to check well the gears of manual three roll mill. We will put the gears outside to rust, then refresh to be heavy strong gears to affording the strength of driving. And our manual three roll mill is heavy cast iron of body, which make the machine more stable during operation.

video

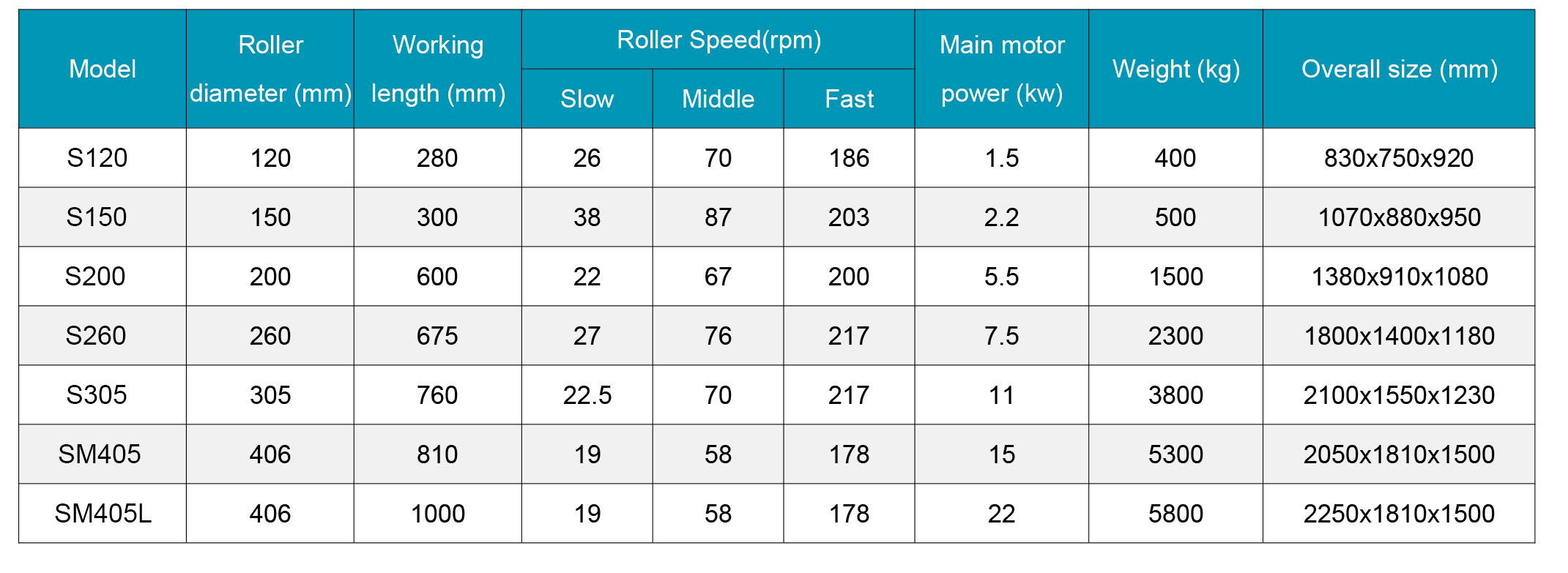

Main Technical Parameters

Application

Related Products

More

-

Vacuum Double Planetary Mixer

A Vacuum double planetary mixer is an essential part of any industry to mixing particular material. A double planetary m...

-

Laboratory Double Planetary Mixer

Laboratory double planetary mixer is a kind of non-standardized strong mixing and mixing equipment developed by FLE for ...

-

Hydraulic Lifting High Speed Disperser

The hydraulic lift high speed disperser has the characteristics of simple operation and high flexibility.The hydraulic l...

-

SMP Agitator bead mill

This SMP Agitator bead mill is used in the paint, ink, and coating industries to ready the equal-sized particles of a pa...

-

TRS-Three Roll Mill For Lipstick

TRS Three roll mill is widely used in milling paste material including paint, inks, China ink, pigment, coatings, food, ...

-

Basket Mill Machine

What is a FLE Basket Mill? Our basket mill combines dispersing and grinding into a single machine that is suitable for g...

News

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

Bead Mill

- SMP Agitator bead mill

- Zirconia beads for sale|Zirconia beads price

- Wet Bead Mill|Bead Mill For Sale

- Sand Mill Machine|Sand Mill For Paint

- Sand Mill|Wet Grinding Equipment Manufacturer

- Bead Mill Machine

- Vertical sand mill

- Bead mill for paint

- Horizontal sand mill

- Turbine bead mill

- Lab bead mill

- Nano Mill

- Vertical Bead Mill

- Bag Filter

- Zirconia Beads

- Pearl Mill

- Dyno mills

- Horizontal Bead Mill

- Agitator bead mill

- Sand Mill

-

Three Roll Mill

-

Twin Shaft Disperser

-

High Speed Disperser

-

Basket Mill

-

High Shear Mixer

-

Double Planetary Mixer

-

Chemical Reactor

-

Kneader

-

Filling Machine

-

Multi-Shaft Mixer

-

Attritor Mill

-

Ribbon Blender

-

Pneumatic Mixer

-

Static Mixer

-

Nitrogen Generator

-

Production Line

- Tricks About Ointment Mill You Wish You ...

- A deep insight into Sand Mill Machine

- What is the difference between dyno mill...

- How To Choose Vertical Bead Mill or Hori...

- What is a three roll mill machine?

- Specification of high speed disperser an...

- Three Roll Mills: Their mechanism, advan...

- high speed disperser machine application

- Faults and Trouble Shooting Methods of H...

- How to operate High-Speed Disperser