-

Equipments

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Or Contact Info

-

Coating

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Adhesives

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Agrochemistry

-

-

Agrochemistry

- Emulsifiable Concentrate

- Suspension Concentrate

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Battery

-

-

Battery

- Battery Slurries

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Cosmetic

-

-

Cosmetic

- Lipstick

- Eyebrow Pencil

- Ointment

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Quality Bead mill Manufacturer From China

The bead mill is one of the most advanced and efficient grinding equipment with wide material adaptability. The entire grinding cavity has a narrow space, and the gap between the levers is small. It has the characteristics of intensive grinding energy. It is equipped with a high-performance cooling system and automatic control system. , it can easily realize the long-term processing and continuous discharge of materials. After the continuous upgrading and transformation of FLE engineers, the production efficiency of the bead mill can reach twice that of the ordinary bead mill. A bead mill, also known as a sand mill, is mainly used for wet grinding of chemical liquid products, electronic paste, ink, and paint. According to the performance, bead mills can be divided into horizontal bead mills, basket bead mills, vertical bead mills, etc.

The bead mill is mainly composed of the body, the grinding drum, the sanding disc (lever), the grinding medium, the motor, and the feeding pump. The FLE bead mill manufacturer sets the function of controlling the speed of the feeding, mainly for the control of the feeding pump, not only that, the grinding media of the bead mill can be of different types. For example, the commonly used grinding media are generally divided into zirconia beads, glass beads, zirconium silicate beads, etc. The grinding effect of different grinding media is also different.

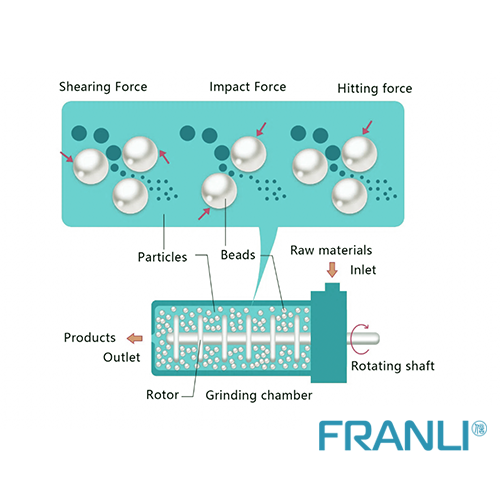

Bead mill design principle:

The bead mill adopts an eccentric disc grinding structure and is arranged in sequence. The system overcomes the disadvantage of uneven distribution of grinding media in traditional grinding machines, enabling the grinding media to obtain large energy transfer and high grinding efficiency. Sealing, good sealing effect, and reliable operation, the separation system adopts a large flow ldc dynamic grid slot separator, the discharge port will not be blocked under large flow conditions, the flow area is up to 0.05-2.0mm, and 0.1 mm can be used. Grinding media above mm.

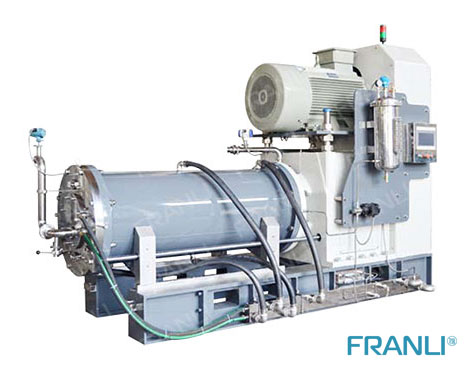

The FLE horizontal bead mill adopts the closed design of the eccentric disc grinding chamber. The grinding discs are installed on the stirring shaft in sequence, which overcomes the disadvantages of uneven distribution of grinding media and poor particle size distribution after grinding in traditional horizontal bead mills. Under the action of the material pump, it enters the grinding chamber. The design of the inlet is at one end of the drive connection flange. The flow direction of the material is opposite to the bottom end of the mechanical bearing, which greatly reduces the pressure on the mechanical seal and prolongs its service life. During the high-speed operation of the eccentric disk, the mixture of the material and the grinding medium move relatively, so that the solid particles of the material are effectively dispersed, sheared, and ground, and after passing through the dynamic large-flow rotor gap separation filter, the product with perfect fineness is obtained. Due to different products, the grinding process has certain differences. The factory can adopt independent batch circular grinding and series grinding processes.

Features of FLE bead mills

1. The medium distribution in the grinding chamber of the horizontal bead mill is uniform, the grinding efficiency is high, the start-up with load is easy, the operation is convenient, and it can be designed to be large. However, the energy density (installed power per unit volume) is low, so the grinding fineness is limited;

2. The medium distribution of the vertical bead mill is uneven, the grinding efficiency is low, and it is difficult to start with the load. The advantage is that there is no mechanical seal and the structure is simple;

3. The horizontal bar grinding bead mill has high energy density, short grinding cylinder, large filtering area of media separator, short material residence time, good heat dissipation effect, high grinding efficiency, and narrow product particle size distribution. Generally used for large flow circulating grinding process of difficult-to-grind materials;

4. The vertical bar bead mill not only has pins arranged on the stirring shaft but is also often arranged on the inner wall of the cylinder. High energy density and high grinding strength. Mainly used for high viscosity materials, such as offset printing ink, and uv ink production.

FLE is a bead mill manufacturer and supplier with 20+ manufacturing experience. Its bead mills have several invention patents and obtained several certificates, helping factories in dozens of countries to solve the grinding problems and efficiency, if you are looking for a suitable bead mill manufacturer, you can get in touch with FLE directly.

Copyright Notice :

This article only represents the author's point of view.

This article is published under the authorization of the author.

Source:

This article address : Quality Bead mill Manufacturer From China

Related Suggestion:

Double planetary mixer new type of mixing equipment

Multiple paddle options of Double Planetary Mixer

Double planetary mixer is the first choice for paste materials

Multiple mixing tanks with double planetary mixer

Double planetary mixer for chemical products

Double planetary mixer can be vacuum feeding

Related Products

-

Vacuum Double Planetary Mixer

A Vacuum double planetary mixer is an essential part of any industry to mixing particular material. A double planetary m...

-

Laboratory Double Planetary Mixer

Laboratory double planetary mixer is a kind of non-standardized strong mixing and mixing equipment developed by FLE for ...

-

Hydraulic Lifting High Speed Disperser

The hydraulic lift high speed disperser has the characteristics of simple operation and high flexibility.The hydraulic l...

News

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

- Tricks About Ointment Mill You Wish You ...

- A deep insight into Sand Mill Machine

- What is the difference between dyno mill...

- How To Choose Vertical Bead Mill or Hori...

- What is a three roll mill machine?

- Specification of high speed disperser an...

- Three Roll Mills: Their mechanism, advan...

- high speed disperser machine application

- Faults and Trouble Shooting Methods of H...

- How to operate High-Speed Disperser