-

Equipments

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Or Contact Info

-

Coating

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Adhesives

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Agrochemistry

-

-

Agrochemistry

- Emulsifiable Concentrate

- Suspension Concentrate

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Battery

-

-

Battery

- Battery Slurries

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Cosmetic

-

-

Cosmetic

- Lipstick

- Eyebrow Pencil

- Ointment

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

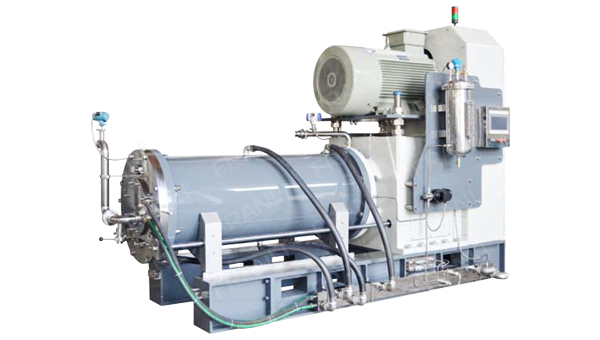

Horizontal Bead Mill

FLE is the manufacture of horizontal bead mill(PDF documents related to FLE Horizontal BEAD MILL:

FLE is the manufacture of horizontal bead mill(PDF documents related to FLE Horizontal BEAD MILL:![]() ), we have export more than 20+ countries for different industries. Here introduce our horizontal bead mill of disc type.

), we have export more than 20+ countries for different industries. Here introduce our horizontal bead mill of disc type.

Horizontal Bead Mill is used for the grinding of a solid-liquid two-phase system. In the grinding process, the material is pumped into the Horizontal Bead Mill, and the rotating grinding disc transfers energy to the beads. The beads impact the material and grind it to the required fineness. The Horizontal Bead Mill is suitable for fine grinding of materials, which can grind materials to the micron or sub-micron fineness range, and the particle size distribution is concentrated, and the energy consumption per unit output is low.

The composition of the Horizontal Bead Mill

The frame of Horizontal Bead Mill

The frame is used for bearing the bearing seat, the mixing shaft, the grinding cylinder, and the motor. The Horizontal Bead Mill frame has a compact structure, and the whole is welded with high-quality steel, which is stable and strong, ensuring the stability of the sand mill.

Double mechanical seal of horizontal bead mill

The horizontal bead mill adopts a double-end mechanical seal, which is used in conjunction with a sealing liquid tank to seal the grinding cylinder. The double end faces mechanical seal is equipped with a sealing liquid circulation system and dynamic and static sealing rings. The sealed tank is equipped with a cooling pipe, a liquid level float switch, a compressed air filter, a control valve, and a pressure switch.

The transmission system of the bead mill

The transmission structure adopts cast bearing seats, imported NSK or SKF bearings, wear-resistant oil seals, 40Cr main shaft quenching and tempering treatment, European-style pulleys, SPV belts, and the transmission bearings are cooled and lubricated by adding grease.

Grinding cylinder of bead mill

The grinding cylinder is a closed cylindrical shape with a built-in grinding system and separation system, which is a place for grinding beads to grind materials. The grinding cylinder has a double jacket and is connected with cooling water. There are interfaces for filling and discharging grinding media on the barrel.

Grinding system of bead mill

The grinding system of the sand mill WSD consists of a grinding disc and a spacer mounted on a metal spindle, which is used to transfer energy to the grinding beads. The material of the grinding disc and the spacer is determined according to the nature of the material. It can be made of special wear-resistant steel, and the steel frame is covered with polymer materials. The grinding system of the WSD sand mill is relatively slender and the linear speed is appropriate, which can achieve fine grinding, concentrated particle size distribution, and high grinding efficiency.

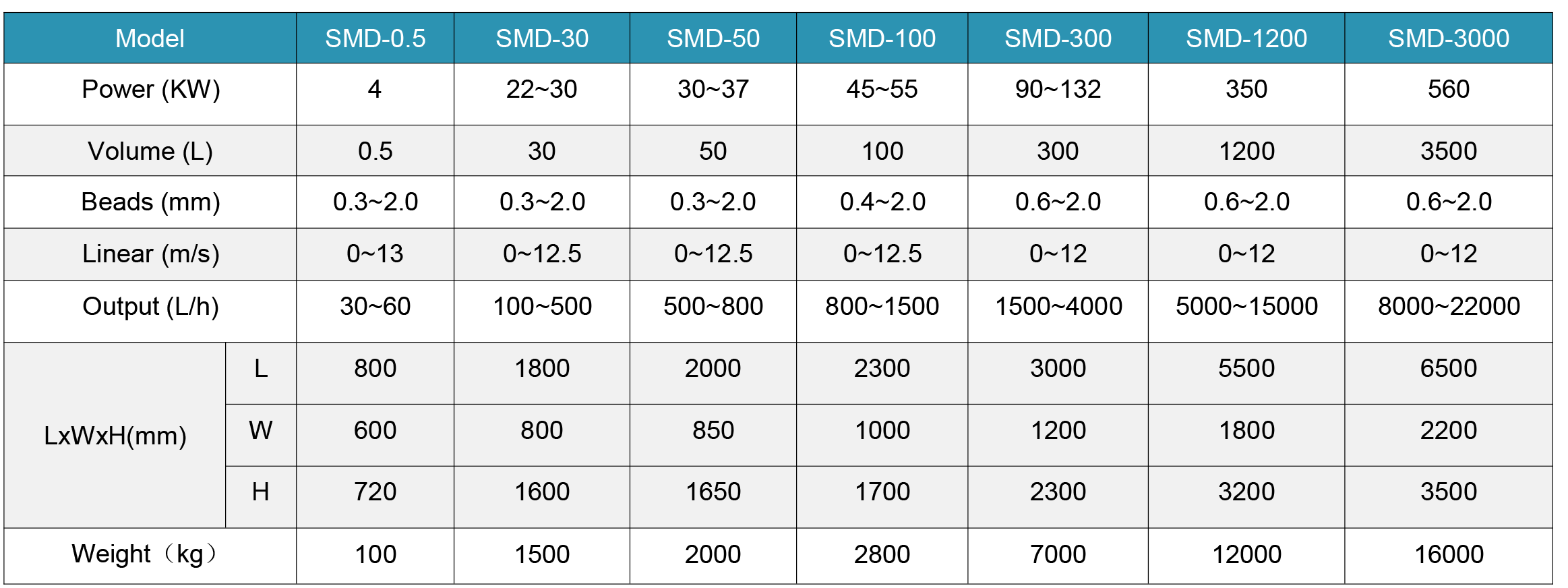

Main Technical Parameters

Application

Related Products

More

-

Vacuum Double Planetary Mixer

A Vacuum double planetary mixer is an essential part of any industry to mixing particular material. A double planetary m...

-

Laboratory Double Planetary Mixer

Laboratory double planetary mixer is a kind of non-standardized strong mixing and mixing equipment developed by FLE for ...

-

Hydraulic Lifting High Speed Disperser

The hydraulic lift high speed disperser has the characteristics of simple operation and high flexibility.The hydraulic l...

-

SMP Agitator bead mill

This SMP Agitator bead mill is used in the paint, ink, and coating industries to ready the equal-sized particles of a pa...

-

TRS-Three Roll Mill For Lipstick

TRS Three roll mill is widely used in milling paste material including paint, inks, China ink, pigment, coatings, food, ...

-

Basket Mill Machine

What is a FLE Basket Mill? Our basket mill combines dispersing and grinding into a single machine that is suitable for g...

News

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

Bead Mill

- SMP Agitator bead mill

- Zirconia beads for sale|Zirconia beads price

- Wet Bead Mill|Bead Mill For Sale

- Sand Mill Machine|Sand Mill For Paint

- Sand Mill|Wet Grinding Equipment Manufacturer

- Bead Mill Machine

- Vertical sand mill

- Bead mill for paint

- Horizontal sand mill

- Turbine bead mill

- Lab bead mill

- Nano Mill

- Vertical Bead Mill

- Bag Filter

- Zirconia Beads

- Pearl Mill

- Dyno mills

- Horizontal Bead Mill

- Agitator bead mill

- Sand Mill

-

Three Roll Mill

-

Twin Shaft Disperser

-

High Speed Disperser

-

Basket Mill

-

High Shear Mixer

-

Double Planetary Mixer

-

Chemical Reactor

-

Kneader

-

Filling Machine

-

Multi-Shaft Mixer

-

Attritor Mill

-

Ribbon Blender

-

Pneumatic Mixer

-

Static Mixer

-

Nitrogen Generator

-

Production Line

- Tricks About Ointment Mill You Wish You ...

- A deep insight into Sand Mill Machine

- What is the difference between dyno mill...

- How To Choose Vertical Bead Mill or Hori...

- What is a three roll mill machine?

- Specification of high speed disperser an...

- Three Roll Mills: Their mechanism, advan...

- high speed disperser machine application

- Faults and Trouble Shooting Methods of H...

- How to operate High-Speed Disperser