-

Equipments

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Or Contact Info

-

Coating

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Adhesives

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Agrochemistry

-

-

Agrochemistry

- Emulsifiable Concentrate

- Suspension Concentrate

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Battery

-

-

Battery

- Battery Slurries

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Cosmetic

-

-

Cosmetic

- Lipstick

- Eyebrow Pencil

- Ointment

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

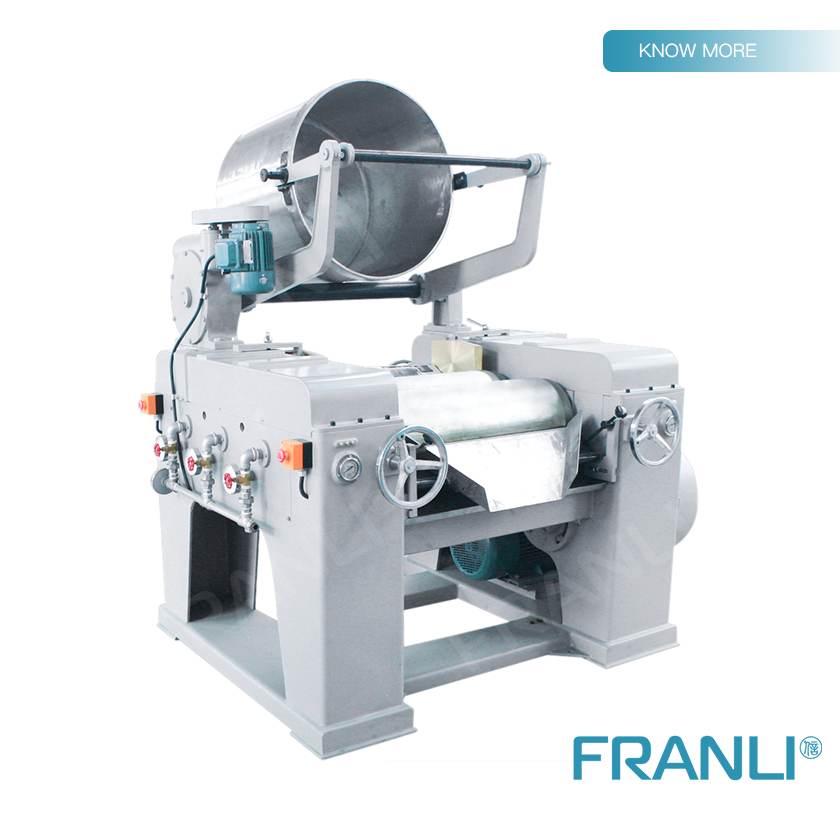

Triple Roll Mill For Carbon Black

The grinding of carbon black is inseparable from the function of the triple roll mill, mainly through the mutual extrusion of the surfaces of the three horizontal rollers of the triple roll mill, and the grinding is carried out at different speeds, and finally, the best grinding effect of carbon black is achieved. Triple roll mills are the most efficient equipment for grinding and dispersing high-viscosity materials.

The working principle of a triple roll mill grinding carbon black

The carbon black is dispersed and pulverized by shear force and pressure to overcome the cohesiveness of the carbon black. When using a three-roller machine, adjustments should be made to ensure high grinding efficiency and smoothness.

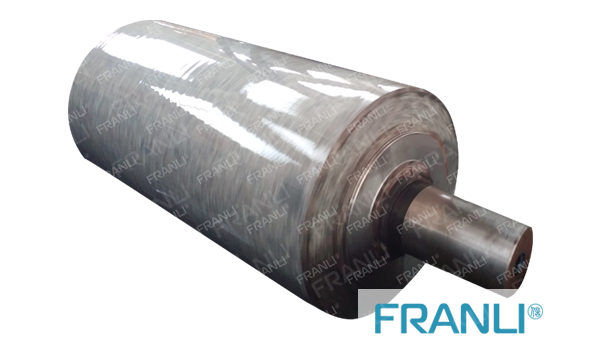

1. Adjust the roller distance according to the production needs, it is stable after fixing, and the pressure between the rollers reaches a constant state.

2. The roller temperature is controlled to ensure that the working temperature remains unchanged and will not turn high or low, otherwise it will affect the viscosity of the system and thus affect the dispersibility of carbon black.

3. If the products produced require high blackness, high gloss, high dispersion and different batch production, the surface of the three-roller machine should be carefully cleaned.

When using a three-roller machine, the material needs to be premixed. To control the number of dispersion media, excessive wear between the media will increase, resulting in a reduction in the particle size of the dispersion media; too little will increase the spacing of the dispersion media and reduce the carbon content. Black dispersion efficiency.

Carbon black fineness after grinding by a triple roll mill

The fineness of carbon black refers to the original particle size of carbon black, which directly affects the blackness, dispersibility, tinting strength, and wettability of carbon black. This paper briefly introduces several indicators of the influence of carbon black particle size.

1. The smaller the original particle size of carbon black, the finer the fineness, the higher its blackness, and the stronger its coloring ability. Can meet the production needs of high-quality products.

2. However, because the particle size is too fine, there are many voids between carbon black particles. There is a lot of air between these voids and it takes longer to get wet. Therefore, the finer the particle size of the high-pigment carbon black, the longer it will take to foam before dispersion.

3. The finer the particle size, the more difficult it is to disperse, and greater force is required during dispersion. This type of carbon black needs a series of post-treatments after the original production is completed to increase the carbon black active material on the surface of the pigment. Al improves its dispersibility.

Therefore, the fineness of carbon black is not as large as possible or as small as possible, it needs to be kept within a certain range, and the ratio depends on the most suitable range required by carbon black products.

Instructions for using the triple roll mill

1. First, carefully check whether the external parts and screws of the triple roll mill are tightened. Details are bigger than anything else.

2. Next, start injecting lubricating oil into the triple roll mill.

3. Turn on the power.

4. Do some simple tests first to see if the handwheel and its rollers around the three-roller grinder are normal.

5. Observe whether there is dirt on the surface of the roller. If the roller surface is dirty, clean it up. Remember to turn off the power and clean the power supply.

6. Note that the gap between the front, middle and rear rollers is 0.5mm if no correction is required.

7. It takes another two minutes to complete the final test before it starts running.

Copyright Notice :

This article only represents the author's point of view.

This article is published under the authorization of the author.

Source:

This article address : Triple Roll Mill For Carbon Black

Previous:How To Choose Vertical Bead Mill or Horizontal Bead Mill?

Next:Quality Bead mill Manufacturer From China

Related Suggestion:

Double planetary mixer new type of mixing equipment

Multiple paddle options of Double Planetary Mixer

Double planetary mixer is the first choice for paste materials

Multiple mixing tanks with double planetary mixer

Double planetary mixer for chemical products

Double planetary mixer can be vacuum feeding

Related Products

-

Vacuum Double Planetary Mixer

A Vacuum double planetary mixer is an essential part of any industry to mixing particular material. A double planetary m...

-

Laboratory Double Planetary Mixer

Laboratory double planetary mixer is a kind of non-standardized strong mixing and mixing equipment developed by FLE for ...

-

Hydraulic Lifting High Speed Disperser

The hydraulic lift high speed disperser has the characteristics of simple operation and high flexibility.The hydraulic l...

News

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

- Tricks About Ointment Mill You Wish You ...

- A deep insight into Sand Mill Machine

- What is the difference between dyno mill...

- How To Choose Vertical Bead Mill or Hori...

- What is a three roll mill machine?

- Three Roll Mills: Their mechanism, advan...

- Specification of high speed disperser an...

- high speed disperser machine application

- Faults and Trouble Shooting Methods of H...

- How to operate High-Speed Disperser