-

Equipments

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Or Contact Info

-

Coating

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Adhesives

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Agrochemistry

-

-

Agrochemistry

- Emulsifiable Concentrate

- Suspension Concentrate

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Battery

-

-

Battery

- Battery Slurries

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Cosmetic

-

-

Cosmetic

- Lipstick

- Eyebrow Pencil

- Ointment

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

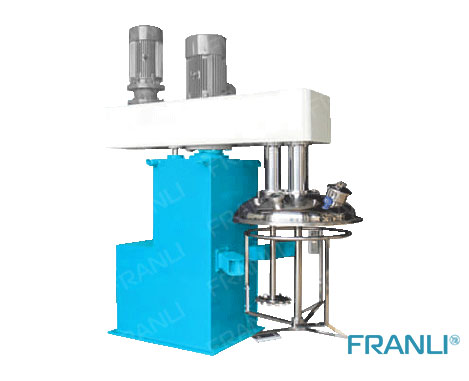

Twin Shaft Disperser

-

FLE Twin Shaft Disperser

FLE Twin Shaft Disperser is composed of a low-speed anchor stirring and two high-speed dispersing di...

-

Plateform Twin Shaft Disperser

This platform twin shaft disperser also named concentric double-shaft multi-function mixer, which is...

-

Butterfly Mixer

This kind of butterfly mixer is used in offset ink, putty etc industry. The butterfly dispersing mix...

-

Dual Shaft Mixer

High-speed disperser is driven by SIEMENS beide motor, speed is 0-1200rpm, adjust by ABB VFD. The lo...

-

Twin Shaft Disperser

The Twin Shaft Disperser is composed of two sets of mixing devices. Different mixing devices can be ...

Twin Shaft Disperser is suitable for mixing and mixing from low viscosity to high viscosity, and the applicable viscosity range is 3000cps~20000cps.

Its main features are the central high-speed rotating zigzag-shaped dispersing disc, which disperses and mixes the materials powerfully, and its speed can be adjusted by the frequency converter. The appropriate speed can be selected according to the process requirements to achieve the best dispersion effect. The low-speed paddle moves in a circular motion around the wall of the barrel and is equipped with a Teflon scraper, which can scrape the material adhering to the wall of the barrel and push the material on the side of the barrel to the center to prevent dead ends and distortion of the formula. At the same time, it is easy to clean. High and low speed can be operated separately according to needs. The whole machine is compact and runs smoothly. According to the working environment, it can be divided into ordinary type and explosion-proof type. This machine is an explosion-proof type.

Main technical parameters 5KL TSD

1. Twin Shaft Disperser motor power: ABB OR SIEMENS 132KW

2. Twin Shaft Disperser speed: 0~1450rpm;

3. Inverter 132kw ABB

4. Diameter of the dispersion plate: φ400mm

5. Low-speed shaft motor power: 30KW

6. Reducer: NORD

7. Low-speed shaft speed: 18rpm;

8. Low-speed blade diameter: φ1440 mm

9. Oil pump motor: 3kw ABB motor

10. Lifting stroke: 900mm

operation

Preparation before operation: This machine has 1 electrical cabinet and 1 full explosion-proof operation box. The electrical cabinet is placed in the power distribution room or other places isolated from the site. The full explosion-proof operation box is placed on the platform or wall. Please a qualified electrician. Connect the wires according to the electrical schematic diagram. Add 46# hydraulic oil to the oil mark position in the hydraulic station, and check whether there is lubricating oil in the reducer (it has been added before leaving the factory).

Trial run: jog the up button to check whether the oil pump motor wiring is correct, then press the up button to raise the equipment to the highest position, and check whether the up limit is working. Press the down button again and reciprocate 2~3 times to check whether the equipment is shaking or crawling when it is rising or falling.

Respectively jog the main engine and scraper motor start buttons to check whether the direction of rotation is counterclockwise. Press the main engine and scraper motor operation buttons respectively, and slowly rotate the speed control button to the right to 300~500RPM to check the stability of the whole machine, and then slowly rotate to the highest point to check whether the whole machine is running smoothly and whether there is abnormal noise. If there is, stop the operation and operate again after troubleshooting.

VEDIO

Production Line

-

PCB INK Machine line

FLE supplies all equipments for the production of PCB inks, from the powder feeding station to the filling part.

-

Offset Ink, UV Ink machine line

The FLE engineering company, offer the full set of UV INK Production Line, we can make the full drawing according with your factory size, fo...

-

Offset Ink machine line

FLE is specialized in offset ink full line production for 20+ years. Helped customer save the cost, save the man power, also save the space....

Equipments

News

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

Bead Mill

- SMP Agitator bead mill

- Zirconia beads for sale|Zirconia beads price

- Wet Bead Mill|Bead Mill For Sale

- Sand Mill Machine|Sand Mill For Paint

- Sand Mill|Wet Grinding Equipment Manufacturer

- Bead Mill Machine

- Vertical sand mill

- Bead mill for paint

- Horizontal sand mill

- Turbine bead mill

- Lab bead mill

- Nano Mill

- Vertical Bead Mill

- Bag Filter

- Zirconia Beads

- Pearl Mill

- Dyno mills

- Horizontal Bead Mill

- Agitator bead mill

- Sand Mill

-

Three Roll Mill

-

Twin Shaft Disperser

-

High Speed Disperser

-

Basket Mill

-

High Shear Mixer

-

Double Planetary Mixer

-

Chemical Reactor

-

Kneader

-

Filling Machine

-

Multi-Shaft Mixer

-

Attritor Mill

-

Ribbon Blender

-

Pneumatic Mixer

-

Static Mixer

-

Nitrogen Generator

-

Production Line

- Tricks About Ointment Mill You Wish You ...

- A deep insight into Sand Mill Machine

- What is the difference between dyno mill...

- How To Choose Vertical Bead Mill or Hori...

- What is a three roll mill machine?

- Specification of high speed disperser an...

- Three Roll Mills: Their mechanism, advan...

- high speed disperser machine application

- Faults and Trouble Shooting Methods of H...

- How to operate High-Speed Disperser