-

Equipments

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Or Contact Info

-

Coating

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Adhesives

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Agrochemistry

-

-

Agrochemistry

- Emulsifiable Concentrate

- Suspension Concentrate

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Battery

-

-

Battery

- Battery Slurries

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Cosmetic

-

-

Cosmetic

- Lipstick

- Eyebrow Pencil

- Ointment

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Ointment Mill

The ointment mill is also called Lab three roll mill. It is mainly used for the fine grinding of high-viscosity liquid slurries such as various paints, coatings, plastics, etc. The ointment mill has three rollers installed on the rack, and the centers are on the same straight line. The factory can be installed horizontally or slightly inclined. When the slurry passes through the surface of the three rollers, the three rollers are repeatedly squeezed at the adjusted speed, and then the product meets the standard.

Generally speaking, when the ointment mill is working, the extrusion speed is not the same, and the roller can be cooled by passing water through the hollow. The material is generally added at the position of the middle roller and the rear roller, and the directions of the three rollers are different, and the rotation speed increases sequentially from back to front, to achieve the most perfect grinding effect. After the material is ground, it is generally necessary to use a scraper to scrape. Many manufacturers set up the scraping place for the material on the front roller, so the efficiency problem can be solved to a large extent.

The role of ointment mills is particularly great. They are especially suitable for processing materials with high viscosity and high requirements for material fineness. In the grinding industry, ointment mills are known as one of the current wet grinding equipment with the best grinding fineness. First, because its volume is much smaller than that of the normal three roll mill, the ointment mill is much smaller, so it is a small experimental device. But in order to meet the needs of preliminary experiments, it can provide a large amount of accurate data for large-scale production.

ointment mill advantage

1. It can achieve very high fineness when grinding high-viscosity materials.

2. The ointment mill is suitable for a variety of materials, and according to the different viscosity of the material, the factory can adjust the arc of the roller and does not affect the requirements for fineness.

3. The structure is simple, and workers can manually adjust the gap between the rollers.

4. The roller can be cooled by water, and the cooling speed is still very fast without harming the machine.

5. The ointment mill can be equipped with an explosion-proof configuration

6. The material of the roller shaft can be customized, such as alloy steel, zirconia ceramics, alumina ceramics, etc.

ointment mill cleaning method

Ointment mills are usually used in coatings, paints, and other chemical products, so many factories are worried about cleaning. First of all, it is equipped with a water cooling system. During or after use, there is no need to worry about serious wear and tear. The factory can manually Open the drum, and follow the manual to clean it manually. The factory can clean it frequently without damaging the machine body, usually by wiping.

Precautions for use:

1. It is forbidden to use the water cooling system when it is not turned on.

2. The maximum bearing temperature of the rollers at both ends is generally 100 degrees.

3. If non-material hard objects appear in the roller, such as iron blocks. Please press the pause immediately and take it out in time to avoid damage to the inside of the body.

4. Adjust the front and rear rollers at any time, and pay attention to the status of the rollers to prevent linear expansion.

5. When cleaning the body or inside, the power supply must be cut off.

video

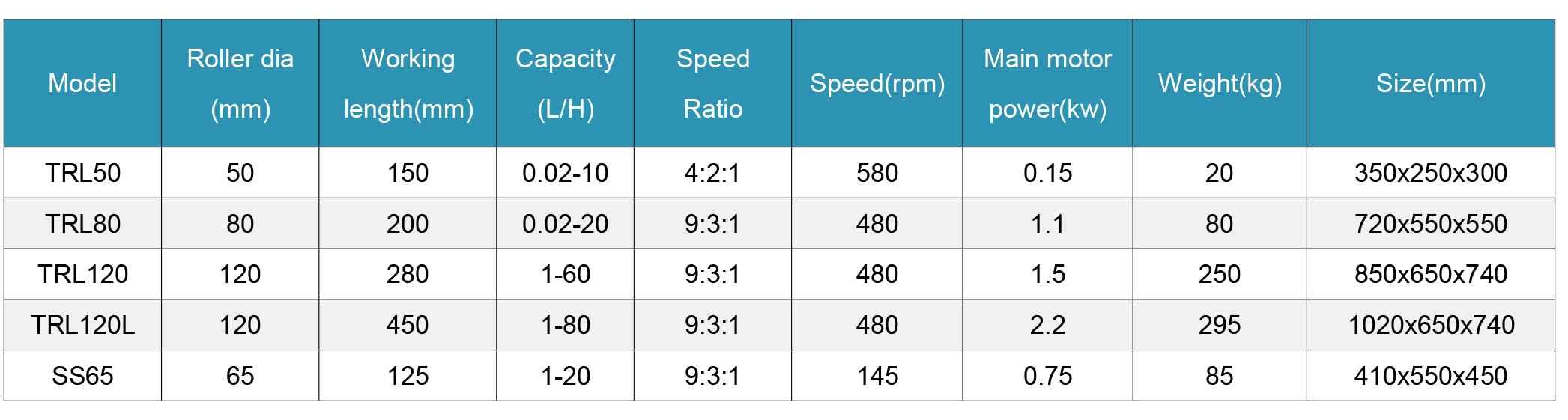

Main Technical Parameters

Application

Related Products

More

-

Vacuum Double Planetary Mixer

A Vacuum double planetary mixer is an essential part of any industry to mixing particular material. A double planetary m...

-

Laboratory Double Planetary Mixer

Laboratory double planetary mixer is a kind of non-standardized strong mixing and mixing equipment developed by FLE for ...

-

Hydraulic Lifting High Speed Disperser

The hydraulic lift high speed disperser has the characteristics of simple operation and high flexibility.The hydraulic l...

-

SMP Agitator bead mill

This SMP Agitator bead mill is used in the paint, ink, and coating industries to ready the equal-sized particles of a pa...

-

TRS-Three Roll Mill For Lipstick

TRS Three roll mill is widely used in milling paste material including paint, inks, China ink, pigment, coatings, food, ...

-

Basket Mill Machine

What is a FLE Basket Mill? Our basket mill combines dispersing and grinding into a single machine that is suitable for g...

News

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

Bead Mill

- SMP Agitator bead mill

- Zirconia beads for sale|Zirconia beads price

- Wet Bead Mill|Bead Mill For Sale

- Sand Mill Machine|Sand Mill For Paint

- Sand Mill|Wet Grinding Equipment Manufacturer

- Bead Mill Machine

- Vertical sand mill

- Bead mill for paint

- Horizontal sand mill

- Turbine bead mill

- Lab bead mill

- Nano Mill

- Vertical Bead Mill

- Bag Filter

- Zirconia Beads

- Pearl Mill

- Dyno mills

- Horizontal Bead Mill

- Agitator bead mill

- Sand Mill

-

Three Roll Mill

-

Twin Shaft Disperser

-

High Speed Disperser

-

Basket Mill

-

High Shear Mixer

-

Double Planetary Mixer

-

Chemical Reactor

-

Kneader

-

Filling Machine

-

Multi-Shaft Mixer

-

Attritor Mill

-

Ribbon Blender

-

Pneumatic Mixer

-

Static Mixer

-

Nitrogen Generator

-

Production Line

- Tricks About Ointment Mill You Wish You ...

- A deep insight into Sand Mill Machine

- What is the difference between dyno mill...

- How To Choose Vertical Bead Mill or Hori...

- What is a three roll mill machine?

- Specification of high speed disperser an...

- Three Roll Mills: Their mechanism, advan...

- high speed disperser machine application

- Faults and Trouble Shooting Methods of H...

- How to operate High-Speed Disperser