-

Equipments

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Or Contact Info

-

Coating

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Adhesives

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Agrochemistry

-

-

Agrochemistry

- Emulsifiable Concentrate

- Suspension Concentrate

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Battery

-

-

Battery

- Battery Slurries

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Cosmetic

-

-

Cosmetic

- Lipstick

- Eyebrow Pencil

- Ointment

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

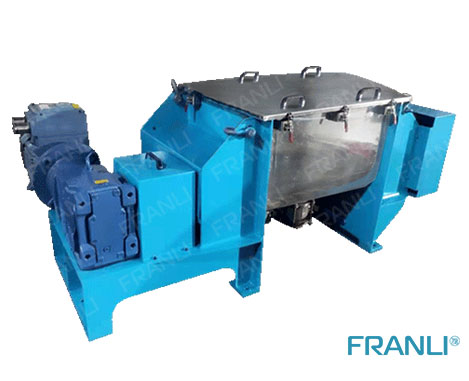

Ribbon Blender

As some user departments don’t know about the Ribbon blender, so they may not choose the right machine to put into production, we should follow some ways so that the Ribbon blender can run stable, and meet the requirement of production and working. To get more convenience when purchasing Ribbon blenders, here we list some questions which we should pay attention to when purchasing Ribbon blenders.

We should pay attention to the working principle of the product when purchasing Ribbon blender, if using Ribbon blender in mixing work, there will be some differences between horizontal Ribbon blender and ordinary Ribbon blender, The blade of this equipment is much smaller than outside, but the width is much bigger than outer equipment, this kind of way is better for transport the raw material and can make the raw material go to a different direction, so we should pay attention to above points when purchasing Ribbon blender.

There are also some differences in the discharge methods selected for different types of horizontal Ribbon blenders.

However, how the raw materials are discharged after processing has a great relationship with the valve selected by the equipment. If the user does not know much about the Ribbon blender, it is recommended that people choose according to the process characteristics of the equipment.

When choosing a Ribbon blender, firstly, determining whether the product meets the actual application requirements, and then check whether the design and production of the equipment meet the standard requirements and choose the reliable manufacturer, These are the issues that need to be paid attention to when purchasing Ribbon blender.

1. For materials with different specific gravities, apart from the different structural strength and power of the ribbon mixer, the structure of the discharge port, rotor, body, and even the performance parameters such as speed are often different. It cannot be simply looked at. For local enhancement or power scaling. For example, the ribbon mixer for mixing hops generally uses a double-headed double-layer wide ribbon, while the ribbon mixer for mixing iron-red powder usually uses a single-layer interlaced spiral ribbon. The other structures of the two are also very different, and the speed difference is also very big.

2. For materials with finer particle size, special attention should be paid to the tightness of the ribbon mixer, and the residual amount should also be carefully considered. For example, when mixing flour with a double-shaft paddle weightless mixer, it is best to use a 90° full-length door, a self-cleaning system, an oblique wedge discharge door, and a shaft end air seal structure at the same time, to better ensure Sealing and reducing residue, in addition, it is best to use the top cloth bag exhaust to replace the return air duct, to avoid excessive fine flour spurting out of the return air duct during mixing.

3. Multi-directional consideration of the influence of other special physical properties on the selection of ribbon mixers. If the fluidity is poor or the liquid is added more materials, the colters, flying knives, crushing rollers, and other mechanisms with strong shearing and mixing action can be reasonably selected according to the specific conditions; the mechanisms with faster wear should be treated with wear resistance or designed into Can be adjusted and replaced; equipment that needs to be cleaned frequently due to material adhesion should be equipped with self-cleaning devices such as scrapers and convenient and quick cleaning doors; for materials whose shape or particle state does not allow damage, container rotary mixers are suitable. Mainly rely on convection mixing and diffusion mixing, and the mixing process is relatively gentle equipment, etc.

4. For the mixing of materials that need to be heated or accompanied by chemical reactions, in addition to selecting appropriate production materials and temperature control structures, it is also necessary to pay attention to the effect of temperature changes on the ribbon mixer. For example, it is best to use a small opening structure for the discharge door. If a large opening structure must be used, an oblique wedge discharge door must be used with automatic compensation capabilities to prevent the discharge part from being thermally deformed and reducing the seal. Reliability; At the same time, necessary linear expansion compensation measures should be taken when designing the main shaft and rotor of the ribbon mixer.

5. Installation space is also an issue that often needs to be considered when choosing a ribbon mixer. For example, ribbon mixers are generally suitable for occasions with large areas and limited height, while vertical mixers are the opposite. Vertical mixers are suitable for occasions with narrow space. Gravity-free mixers and v-type mixers are compatible with others of the same specification. Compared with hybrid equipment, it generally occupies a much larger space, but it also has the advantage of being easy to move and arrange. Of course, in addition to the installation dimensions of the ribbon mixer itself, reasonable on-site layout and installation methods can also effectively improve the installation space conditions of the mixer.

Production Line

-

PCB INK Machine line

FLE supplies all equipments for the production of PCB inks, from the powder feeding station to the filling part.

-

Offset Ink, UV Ink machine line

The FLE engineering company, offer the full set of UV INK Production Line, we can make the full drawing according with your factory size, fo...

-

Offset Ink machine line

FLE is specialized in offset ink full line production for 20+ years. Helped customer save the cost, save the man power, also save the space....

Equipments

News

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

Bead Mill

- SMP Agitator bead mill

- Zirconia beads for sale|Zirconia beads price

- Wet Bead Mill|Bead Mill For Sale

- Sand Mill Machine|Sand Mill For Paint

- Sand Mill|Wet Grinding Equipment Manufacturer

- Bead Mill Machine

- Vertical sand mill

- Bead mill for paint

- Horizontal sand mill

- Turbine bead mill

- Lab bead mill

- Nano Mill

- Vertical Bead Mill

- Bag Filter

- Zirconia Beads

- Pearl Mill

- Dyno mills

- Horizontal Bead Mill

- Agitator bead mill

- Sand Mill

-

Three Roll Mill

-

Twin Shaft Disperser

-

High Speed Disperser

-

Basket Mill

-

High Shear Mixer

-

Double Planetary Mixer

-

Chemical Reactor

-

Kneader

-

Filling Machine

-

Multi-Shaft Mixer

-

Attritor Mill

-

Ribbon Blender

-

Pneumatic Mixer

-

Static Mixer

-

Nitrogen Generator

-

Production Line

- Tricks About Ointment Mill You Wish You ...

- A deep insight into Sand Mill Machine

- What is the difference between dyno mill...

- How To Choose Vertical Bead Mill or Hori...

- What is a three roll mill machine?

- Three Roll Mills: Their mechanism, advan...

- Specification of high speed disperser an...

- high speed disperser machine application

- Faults and Trouble Shooting Methods of H...

- How to operate High-Speed Disperser