-

Equipments

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Or Contact Info

-

Coating

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Adhesives

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Agrochemistry

-

-

Agrochemistry

- Emulsifiable Concentrate

- Suspension Concentrate

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Battery

-

-

Battery

- Battery Slurries

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Cosmetic

-

-

Cosmetic

- Lipstick

- Eyebrow Pencil

- Ointment

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Digital Ink machine line

Digital ink is widely used in printing or writing pen. China is the biggest country offering the huge amount digital ink all over the world.

Digital ink is widely used in printing or writing pen. China is the biggest country offering the huge amount digital ink all over the world.

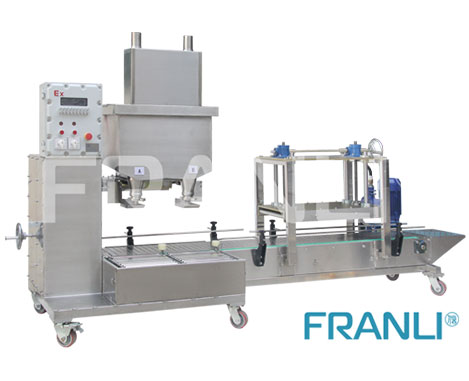

FLE has professional experience for digital ink machine line, we offered hundreds customers to expand production, or build up new project. Here has several process from feeding powder, mixing machines, add color to basic ink, grinding nano digital ink, then adjust the final ink into different color tanks.

Main Parts

|

Twin Shaft Disperser |

Nano Mill |

|

Filling Machine |

Agitator Mixer |

Digital ink is widely used in printing or writing pen. China is the biggest country offering the huge amount digital ink all over the world. Digital ink is colorful ink, with fast drying on the paper. When we go outside, we will found the digital printing machine for customers to printing pics, save the good memories. Digital ink also has good benefit, we got more digital ink machine line inquires from digital ink customers.

FLE has professional experience for digital ink machine line, we offered hundreds customers to expand production, or build up new project. Here has several process from feeding powder, mixing machines, add color to basic ink, grinding nano digital ink, then adjust the final ink into different color tanks.

What are the key points we should focus on?

1. the powder bags station, we normally has 25kg and 500kg, which are different machines. Which bag discharge station also install with dust collection station, most customer factory has center collection dust system, and can not rework again. While this dust collection powder can be pour into tanks, save the cost and save the environment.

2. powder feeding pipe is screwing type.

3. fast speed mixing tank, if needs higher production, we suggest to choose TSD (Twin shaft dispenser) we will focus on the brand of parts, the shaft stable, and the Teflon scrapper blade. We offered the max tank capacity is 10T with jacket

4. Nano bead mill, we have horizontal nano bead mill, also vertical nano mill, pls come to connect with us when you choose. We will account the raw material size, temperature, production capacity, final size,etc. Also you should focus on the size of beads. Nowadays we can add the mini 0.01mm beads into our nano digital ink bead mill. Most machines in the market will be blocked by small beads, while we has own special design with two drivers chamber, wont be blocked anymore. This process may need cycling grinding according with your raw material and final material requirement.

5. low speed mixer (agitator mixer)to adjust the additional chemicals. We has many kinds design mixing type for low speed machines. Which depends on your formula technology.

6. filling machine, has automatic filling machine line, also semi filling machines. Also different bottles has different machines. The accuracy is 0.2%. we normally suggest customer to choose the semi-auto filling machine, and easy washing, also weight-type with Toledo brand.

How about our service?

1. We will read your chemicals data before choosing three roll mill, bead mill machines, make the full drawing according with your material technology.

2. oversea installation and training, testing production

3. working process guide videos, paper manual book

4. local after sales service or other teams near your country.

5. full life technology support

Application

Related Products

More

-

Vacuum Double Planetary Mixer

A Vacuum double planetary mixer is an essential part of any industry to mixing particular material. A double planetary m...

-

Laboratory Double Planetary Mixer

Laboratory double planetary mixer is a kind of non-standardized strong mixing and mixing equipment developed by FLE for ...

-

Hydraulic Lifting High Speed Disperser

The hydraulic lift high speed disperser has the characteristics of simple operation and high flexibility.The hydraulic l...

-

SMP Agitator bead mill

This SMP Agitator bead mill is used in the paint, ink, and coating industries to ready the equal-sized particles of a pa...

-

TRS-Three Roll Mill For Lipstick

TRS Three roll mill is widely used in milling paste material including paint, inks, China ink, pigment, coatings, food, ...

-

Basket Mill Machine

What is a FLE Basket Mill? Our basket mill combines dispersing and grinding into a single machine that is suitable for g...

News

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

Bead Mill

- SMP Agitator bead mill

- Zirconia beads for sale|Zirconia beads price

- Wet Bead Mill|Bead Mill For Sale

- Sand Mill Machine|Sand Mill For Paint

- Sand Mill|Wet Grinding Equipment Manufacturer

- Bead Mill Machine

- Vertical sand mill

- Bead mill for paint

- Horizontal sand mill

- Turbine bead mill

- Lab bead mill

- Nano Mill

- Vertical Bead Mill

- Bag Filter

- Zirconia Beads

- Pearl Mill

- Dyno mills

- Horizontal Bead Mill

- Agitator bead mill

- Sand Mill

-

Three Roll Mill

-

Twin Shaft Disperser

-

High Speed Disperser

-

Basket Mill

-

High Shear Mixer

-

Double Planetary Mixer

-

Chemical Reactor

-

Kneader

-

Filling Machine

-

Multi-Shaft Mixer

-

Attritor Mill

-

Ribbon Blender

-

Pneumatic Mixer

-

Static Mixer

-

Nitrogen Generator

-

Production Line

- Tricks About Ointment Mill You Wish You ...

- A deep insight into Sand Mill Machine

- What is the difference between dyno mill...

- How To Choose Vertical Bead Mill or Hori...

- What is a three roll mill machine?

- Specification of high speed disperser an...

- Three Roll Mills: Their mechanism, advan...

- high speed disperser machine application

- Faults and Trouble Shooting Methods of H...

- How to operate High-Speed Disperser