-

Equipments

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Or Contact Info

-

Coating

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Adhesives

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Agrochemistry

-

-

Agrochemistry

- Emulsifiable Concentrate

- Suspension Concentrate

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Battery

-

-

Battery

- Battery Slurries

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Cosmetic

-

-

Cosmetic

- Lipstick

- Eyebrow Pencil

- Ointment

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

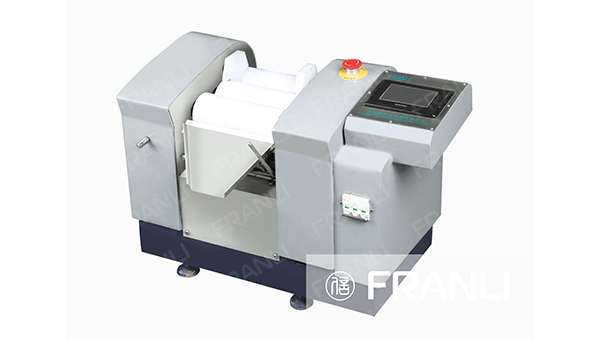

How to choose the ointment mill suitable for the industry

Ointment mill is the machinery used to mix, refine, disperse, or homogenize viscous materials fed into the mill with shear forces caused by three horizontal rolls rotatable towards opposite directions and at varying speeds relative to each other. The product is pulled across the roller spaces. Active substances and powder clumps are disrupted and homogenized, eliminating smear and creating topical results. This results in an effective and elegant ointment.

Ointment mill

How does it work?

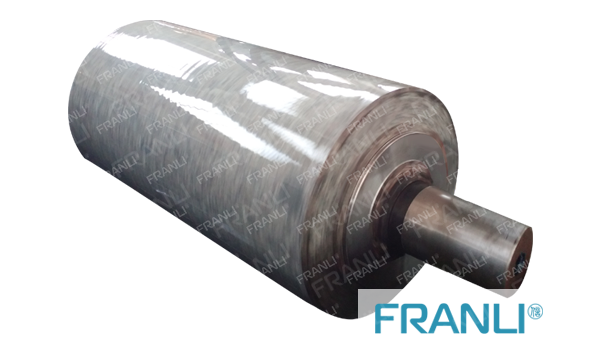

At a progressively greater rate, three adjacent rolls of an Ointment mill, named the feed roll, the middle roll, and the delta roll, rotate. Material is fed between the feed roll and the center roll, typically in paste form. Because the distance between rolls is reducing, most of the paste remains in the feed area initially. Due to the different rotational speeds of the two rolls, the section that makes this by the first running nip experiences very high cistern force. Upon exiting, the material remaining on the middle roll passes between the center roll and the trailing roll through the second nip.

The fast speed of the apron roll and normally smaller space between the feed and the central rolls imposes even more heavy shear force. The processed material is subsequently struck out of the tab roll by a knife blade and the paste rolls through the apron. To maximize dispersion, the frying cycle may repeat numerous times. The spacing between the rolls can be changed and maintained mechanically or hydraulically. The gap distance is typically much larger than the size of the particle. In some operations, the distance between the gaps is gradually lowered to the required dispersion level. Normally, the rollers are water-cooled inside.

ointment mill roller

Where is it used widely?

Ointment mills have been widely used for mixing ink printing, thick-film electronic inks and high-performance ceramics, cosmetics, plastisols, carbon/graphite, paints, medicines, chemicals, glass coatings, pigment coatings, adhesives, dental composites, sealants, and foods. They are also used in the production of cable covers, electronics, soap, and artificial plastics with the new developments in technology.

Small bench models are used for bench-top development, laboratory work, and low-volume manufacturing. Larger bench and floor models are built to meet a variety of production needs, ranging from pilot plants to high-volume production. This process has the added benefit of milling high viscosity pastes, and the high surface contact with the cooled rollers keeps the temperature low despite the high amount of dispersion work put in. One significant disadvantage is that the large open area of paste on the rollers causes volatiles to be lost.

ointment mill roller

Different series of Ointment Mill:

- TRS & TRM Manual: Ointment Mills, the roller gap is controlled by adjustable wheels. TRS & TRM three roller mill is an updated version of the S triple roll mill. Oil-soaked TRS & TRM machine transfer gears (oil box). Keeping the operation running for a longer period with less noise.

- Cooling control system: TRS & TRM three roller machine thermometer installed, easily check the material temperature. Chillers are normally connected to three rolls. Typically by first passing grinding, you can get to 10-20um. While using an ointment mill, transfer gears with grease, and check the chain. However, it is still widely used in the soap and printing industries.

- Hydraulic TRH type: Hydraulic Ointment Mill, with a full hydraulic auto-controlling system. Cooling system: each roller has its cooling system. Hydraulic control: hydraulic pressure blades, roller gaps, and so on.

- Optional installation: PLC system with SIEMENS touching screen, Engineer set grinding formulas based on different viscosity materials.

- TRL Type Lab: Ointment Mill with PLC Touching Screen, which is widely used in the pharmaceutical, ink, cosmetics, and electronics industries. Auto-operation of digital numbers, small size which is the smarter, safer, and faster option which is tailored to meet the needs of various materials

- Heating Type: The gear quality for this type of machine is specially designed because it grinds high viscosity material and is heated with oil or steam. ointment mill machines have full automatic PLC control, a hydraulic system, stable operation, and consistent quality. International brand components are selected. ABB VFD, Siemens Motor, SKF or NSK bearings, SEW, or Nord reducers are examples of standard parts. A roller is made of cast steel with a thickness of 45- 55mm. For your material, you can select from a wide range of ceramic, alloy, and granite rollers. If there are several material formulas, we can program them into the PLC system so that your workers only have to choose numbers by touching the screen and don't have to waste time adjusting the rollers' gap or the blade's pressure.

- There are several types of feeding systems for different viscosities of material. For example, a feeding pressure machine, also known as an extruder machine. A feeding system with a single reducer motor is installed on top. However, if your material has a very high viscosity and you are producing a small batch, we recommend that you feed the material into the rollers with a manual scrapper.

ointment mill feeding port

Merits:

Only the ointment mill used in the dispersing process ensures that all of the product passes through both shear zones. The process is determined by the shear rate between the rollers. The roller spacing and circumferential speed determine this. Breaking up and homogenizing agglomerates and powder clumps. The more precise the processing, the more controlled the energy input.

One of the most prominent manufacturers, FLE, specializes in Ointment mill designs. They designed their Ointment mill which can break open all kinds of pigment, UV ink, offset ink, decorative paints, and Lubricants. In addition to this, this ointment mill also can catch the greatest fineness in the cosmetics/ lipstick and electronics industries. Coming to the quality control of Ointment mills, they will offer the certification of the machine, before shipment. The roller balance, the thickness of the roll, the heating or cooling system, blade pressure, and full pressure system outlet function for materials has been checked thoroughly. For more details visit their official website.

Copyright Notice :

This article only represents the author's point of view.

This article is published under the authorization of the author.

Source:

This article address : How to choose the ointment mill suitable for the industry

Previous:The focus of the high shear mixer

Next:Understanding the Working and Best Practices for Using a 3 Roll Mill

Related Suggestion:

Double planetary mixer new type of mixing equipment

Multiple paddle options of Double Planetary Mixer

Double planetary mixer is the first choice for paste materials

Multiple mixing tanks with double planetary mixer

Double planetary mixer for chemical products

Double planetary mixer can be vacuum feeding

Related Products

-

Vacuum Double Planetary Mixer

A Vacuum double planetary mixer is an essential part of any industry to mixing particular material. A double planetary m...

-

Laboratory Double Planetary Mixer

Laboratory double planetary mixer is a kind of non-standardized strong mixing and mixing equipment developed by FLE for ...

-

Hydraulic Lifting High Speed Disperser

The hydraulic lift high speed disperser has the characteristics of simple operation and high flexibility.The hydraulic l...

News

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

- Tricks About Ointment Mill You Wish You ...

- A deep insight into Sand Mill Machine

- What is the difference between dyno mill...

- How To Choose Vertical Bead Mill or Hori...

- What is a three roll mill machine?

- Three Roll Mills: Their mechanism, advan...

- Specification of high speed disperser an...

- high speed disperser machine application

- Faults and Trouble Shooting Methods of H...

- How to operate High-Speed Disperser