-

Equipments

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Or Contact Info

-

Coating

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Adhesives

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Agrochemistry

-

-

Agrochemistry

- Emulsifiable Concentrate

- Suspension Concentrate

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Battery

-

-

Battery

- Battery Slurries

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Cosmetic

-

-

Cosmetic

- Lipstick

- Eyebrow Pencil

- Ointment

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Three roll mill for ointment

In the pharmaceutical industry, these machines are called the three roll mills as they are widely used to make ointments. Speaking about the basic operating procedure of the machine, it comes with three perfectly positioned rolls.

Throughout the process industries, an three roll mill is utilized to attain a high-quality dispersion in different products, such as gels, pastes, and other semi-solids items. Speaking about ideal applications of the machine, it includes high to medium viscosity materials that are challenging to disperse through a traditional high-speed mixer.

For many years, three roll mill have been utilized in different industries, such as food, paint, ink, pharmaceutical, energy conversion, electronics, energy storage, and more. Everywhere in the industry, where there is a frequent requirement of color changes and small batch production, these machines can be a perfect solution.

Bases for the coil as well as can coating are generally developed using a three-roll mill machine. Why? The major reason behind this is the machine comes with a massive cooling surface as well as a perfect temperature control unit.

Fundamental operating theory of three roll mills

An three roll mill is one type of three roll mill. In the pharmaceutical industry, these machines are called the three roll mills as they are widely used to make ointments. Speaking about the basic operating procedure of the machine, it comes with three perfectly positioned rolls. They are placed horizontally, and they rotate in opposite directions, and the speed will also vary. The material that you need to mill is then placed between the machine’s feed as well as center rolls.

The material adheres to the three roll mill’s rotating surface, and then it starts to spread evenly. During the process, the rollers produce shear forces. The force between the adjacent rolls then breaks the agglomerates in the ointment. The apron roll of the machine functions to transfer the material while producing additional shear forces at a higher level.

While buying an three roll mill, you need to consider some important factors. For example, the distance between the rolls present in the machine should be adjustable. This can greatly affect the throughput as well as the shear level produced by the machine. A common gap setting is 0.001”.

Once done, the processed material is carefully scraped from the roll using a take-off knife. If you want to enhance the dispersion quality and perfect distribution of the particles, then you can repeat the production cycle.

Production of paste or ointment using an three roll mill

Different types of viscous materials, for example, gels, creams, pastes, or ointments, are perfect applications for these machines. These products generally undergo a two-stage process. And the process begins in a traditional batch mixer where the ingredients are perfectly combined, and this is done under an elevated temperature. Once the material cools down, the material is then fed to the machine to obtain the desired dispersion. This process also eradicates visual imprecations or specks in the product.

There are some stubborn agglomerates that are quite challenging to disperse through a conventional agitator. For example, phthalo green, quinacridone violet, and more. You may not get the desired result even if you are using saw-tooth dispersers or rotor/stator mixers. As per different studies, such machines support a limited viscosity range to created sufficient flow in a mixer.

Sometimes, you may need to increase the temperature. This way, you will be able to keep the material in working condition. Multiple heat-sensitive applications can benefit from different alternative processing methods, for example, high shear or low-temperature conditions that an three roll mill can produce. That’s why these machines are quite popular in the pharmaceutical industry.

When it comes to producing very fine particle dispersions in cosmetics, electronic coatings, ceramic, inks, pharmaceuticals, and more, you can always use a three roll mill. Well, only a skilled operator can use the machine to created consistent results, and you can keep the machine running safely. Before you can start using the machine, it is important to test the machine to understand the perfect gap settings for a certain product to optimize the throughput as well as dispersion quality.

Antibiotic ointment a perfect example of three roll mill’s application

A well-known pharmaceutical company who is specialized in making semi-solid as well as liquid product, use a three-roll mill to produce quality antibiotic ointment creams. Speaking about the working process, the production process begins with heating the petrolatum base at around 180-degree F, and then they combine around five different ingredients utilizing a saw-tooth disperser blade. They use a separate tank to melt a triglyceride base at around 110-degree F. Then, another active ingredient is combined with the material.

Then, the processed material is allowed to cool and mixed using a triglyceride batch. Even though the material is combined through a high-speed mixing process, the material can have visible particles and flecks. But this is not a major problem at all. Two to three passes through an three roll mill create a speck-free and visible smooth cream. During the process, the temperature of the product is kept at a particular level by applying cooling water through the rolls.

Enjoy narrow particle distribution

Using the machine, particle sizes can be lowered, and agglomerates are properly dispersed. Thanks to the sufficient crushing force of the rollers. Besides, they are designed to produce high shearing force by the rollers that work at different speeds. By configuring the gap width, you can control the particle size without any issue. For instance, dissolvers and bead mills can produce a better and wider distribution of the particle. So, if you want to produce good-quality and super-fine ointments or creams, then using an three roll mill can be a perfect idea.

Enjoy maximum benefits with a good quality machine

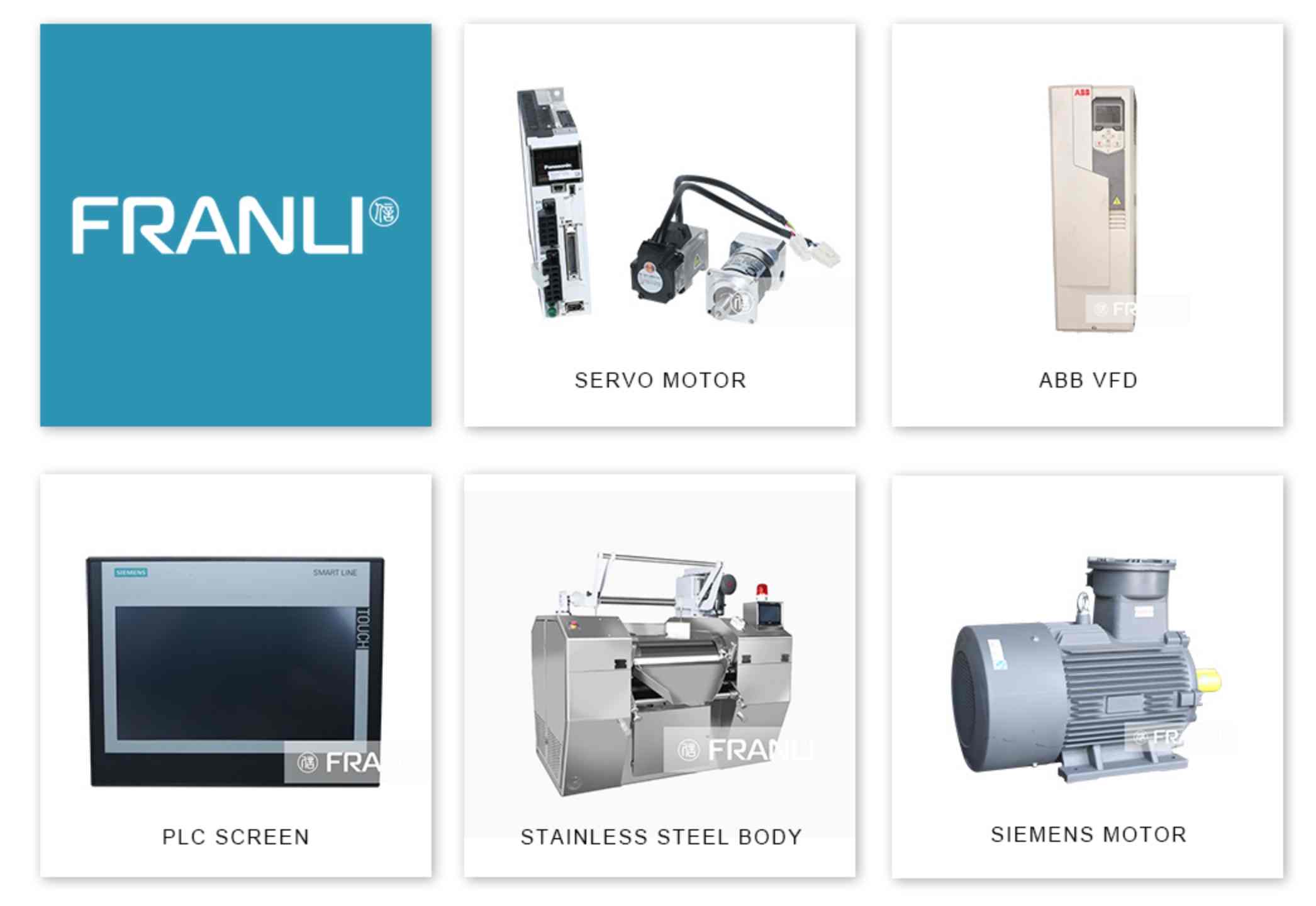

Are you looking for a robust three roll mill to produce good quality ointment and to increase the production capacity of your manufacturing unit? Don’t worry at all and get the three-roll mill developed by Franli. The machine can be used in different applications, for example, solar pasty, cosmetics, ointment, electronic pastes, and more. Equipped with the latest technology and made of high-quality material, the mill can produce narrow particle size and hyper-precise distribution of the material. The best thing about the machines is the users can easily control the rollers by configuring the SIEMENS PLC system. For more details, you can visit the official site of Franli.

Copyright Notice :

This article only represents the author's point of view.

This article is published under the authorization of the author.

Source:

This article address : Three roll mill for ointment

Related Suggestion:

Double planetary mixer new type of mixing equipment

Multiple paddle options of Double Planetary Mixer

Double planetary mixer is the first choice for paste materials

Multiple mixing tanks with double planetary mixer

Double planetary mixer for chemical products

Double planetary mixer can be vacuum feeding

Related Products

-

Vacuum Double Planetary Mixer

A Vacuum double planetary mixer is an essential part of any industry to mixing particular material. A double planetary m...

-

Laboratory Double Planetary Mixer

Laboratory double planetary mixer is a kind of non-standardized strong mixing and mixing equipment developed by FLE for ...

-

Hydraulic Lifting High Speed Disperser

The hydraulic lift high speed disperser has the characteristics of simple operation and high flexibility.The hydraulic l...

News

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

- Tricks About Ointment Mill You Wish You ...

- A deep insight into Sand Mill Machine

- What is the difference between dyno mill...

- How To Choose Vertical Bead Mill or Hori...

- What is a three roll mill machine?

- Three Roll Mills: Their mechanism, advan...

- Specification of high speed disperser an...

- high speed disperser machine application

- Faults and Trouble Shooting Methods of H...

- How to operate High-Speed Disperser