-

Equipments

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Or Contact Info

-

Coating

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Adhesives

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Agrochemistry

-

-

Agrochemistry

- Emulsifiable Concentrate

- Suspension Concentrate

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Battery

-

-

Battery

- Battery Slurries

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Cosmetic

-

-

Cosmetic

- Lipstick

- Eyebrow Pencil

- Ointment

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

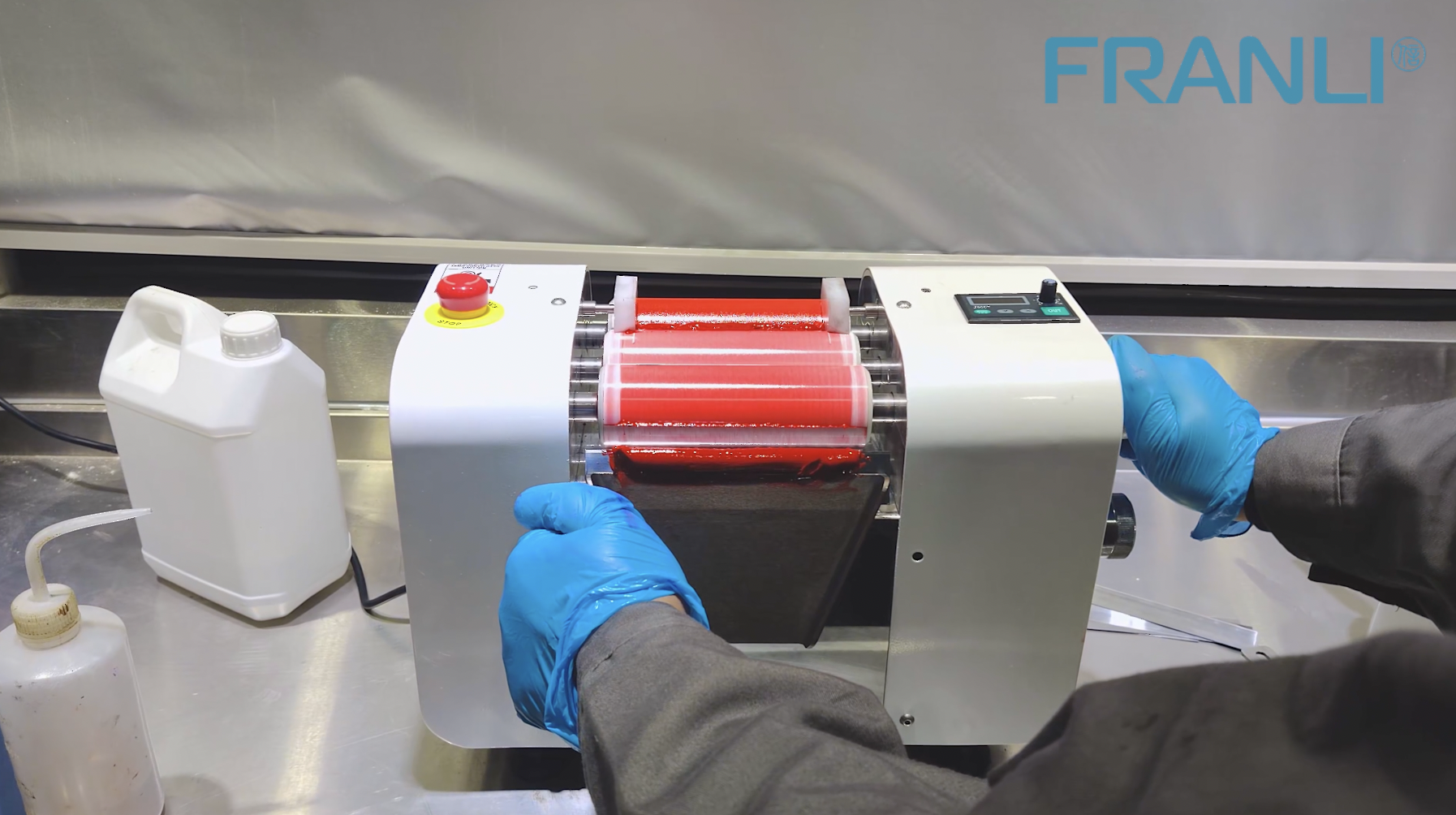

Three Roll Mill Application: Lipstick & Carbon Black

The three roll mill is mainly used for grinding and dispersing materials, and it is mainly used for the manufacture of slurries such as coatings, inks, pigments, and plastics. The working principle of the three roll mill is to achieve the grinding effect by squeezing the surface of the horizontal three-roller and rubbing at different speeds. Three roll mill is the most effective grinding and dispersing equipment for high viscosity materials.

In the process of processing materials, heating and cooling may be required. How does the three roll mill achieve this function? How is the three roll mill used in the process of manufacturing lipstick?

The rolls of a three roll mill can be cooled or heated by injecting cooling water/coolant or heat transfer oil into the roll core. We have a customer who uses heat transfer oil to heat the drum of our machine to 60°C.

Lipsticks and lip balms have higher percentages of fine and coarse particles, because some particles may be repeatedly dispersed due to dispersing forces, while others are not dispersed at all. The three roll mill is the most effective. For each three roll mill, the reduction of particle size and the dispersion of agglomerates are accomplished by the combined action of the rolling pressure between the rollers and the high shear force caused by different roller speeds. Since the entire material is filled into the roller gap, the particle size is precisely controlled and narrowly distributed. Through the adjustment of the roller spacing, the particle size can be easily and accurately processed to the micron level. Therefore, compared with other grinding equipment, the three roll mill can effectively improve the particle size distribution and make the particle size distribution more concentrated.

Application of three roll mill in lipstick production

The production of the lipstick is divided into four main stages, the first and second stage will use a three roll mill. The basic raw materials for making lipsticks include waxes, oils, pigments/pigments. A typical raw material ratio is 20/30% wax, 50/70% grease and 5/15% pigment. In the first stage, the pigment needs to be mixed with an appropriate amount of oil (the ideal ratio of pigment to oil is two parts oil and one part pigment), and then the mixture is ground with a three roll mill to uniformly disperse the pigment polymer. In the second stage, the uniformly dispersed pigment and grease mixture is added to the dissolved wax and remaining oil (or a small amount of aromatherapy can be added) and then reprocessed with a three roll mill to obtain the desired particle size (usually 20 microns) ). A three-roll mixture of uniformly dispersed pigment and oil is added to the dissolved wax and remaining oil (alternatively, a small amount of aromatics can be added) and reprocessed through a three roll mill to obtain the desired particle size (usually 20 microns).

Problems with using a three roll mill lipstick

1. Pigment grinding, since pigments are mostly powder, although the particles are relatively fine, they are often aggregated into lumps, and it is difficult to disperse them evenly when they are directly added to the oil matrix. Therefore, the pigments used must be ground beforehand. In order to make the grinding smooth, it is often necessary to add a small amount of liquid oil to the pigment and mix it, and then use mechanical grinding.

2. The colorant is mixed with the oil base. Generally, the dye is added to the solvent and heated and melted, and then the ground pigment and wax raw materials are added. After melting, the semi-solid oil is added, stirred evenly, and ground while hot; degassing Then add spices and other accessories.

The production of high-quality carbon black is inseparable from the role of the three roll mill. FLE series three roll mill can perfectly realize the method of uniformly dispersing carbon black pulp. The main function of the three roll mill is to rely on pressure and shear force to overcome the cohesion of carbon black to achieve the purpose of pulverizing and dispersing carbon black.

The carbon black three roll mill, with a minimum processing capacity of 0.02L/hour to a maximum of 20L/hour, perfectly solves the user’s transition from laboratory testing to small and medium-scale trial production. The highly innovative design makes the device more compact and can be easily placed on the laboratory desktop. The very friendly human-machine interface is realized by the full-touch industrial control screen. The unique online gap correction and recipe menu functions make it easier to use the equipment so that users no longer face the cold equipment, but control it in an interactive operation mode.

Carbon black is widely used in rubber, plastics, coatings, inks, etc. It can be used as a reinforcing agent, colorant, conductive material, anti-ultraviolet agent, etc. Structural properties affect the application, and its particle size, structure, and surface functional groups have a great impact on the application properties. The particle size of carbon black is an important property. The smaller the particle size, the larger the specific surface area, and the improvement in blackness, tinting strength, conductivity, reinforcement, and UV resistance, but its dispersibility decreases, such as in plastics. , The difficulty of dispersion in coatings and inks increases, and the viscosity increases. Coating and ink liquid systems are prone to poor dispersion problems such as flocculation, thickening, agglomeration, and delamination, which have a lot to do with dispersion equipment. Many carbon black manufacturers use kneaders to disperse color paste, but there are problems such as dead corners and uneven dispersion in stirring, which makes the product less than expected.

While the three roll mill under FLE is running, there is no leakage, uniform discharge, good parallelism of the rollers, and no displacement after use; the carbon black slurry is diluted and tested by scanning electron microscopy (SEM), and it is found that there is no large The micelles showed good dispersibility and met customer requirements.

Advantages of FLE three roll mill

① Three roll mill adopts one cycle, it is possible to completely realize the homogenization and dispersion of the material, reduce the particle size, and break the agglomerated particles. The result is a homogeneous slurry that provides the perfect basis for further processing of the material.

②The three roll mill can adjust the distance between each roller with a touch screen to ensure perfect parallelism of the rollers. The elastically tensioned blade socket ensures constant blade pressure and does not require readjustment during operation.

③Rollers of different materials can be used, the choice of roller and scraper material – from stainless steel to alumina, silicon carbide, and zirconia – to meet various needs.

④The safety device on the three roll mill ensures the maximum safety of the operator, and the machine can be cleaned easily and quickly.

⑤FLE’s first IoT and intelligent three-roll mill solution in the industry solves the problems that customers encounter in the use of data that cannot be quantitatively analyzed, data is lost, equipment is independent of each other, and cannot be managed and controlled through the Internet. It allows customers to analyze the data of the equipment, assign and manage the authority of the employees, and keep the whole process record and backup of the equipment operation process, which is conducive to the research, design, and development of processing parameters. In addition, the intelligent IoT platform can also be connected to equipment platforms such as mixers, three-roll mills, feeders, and homogenizers, and can be connected to online viscometers, mid-infrared, particle size analyzers, and other instruments for online monitoring.

Copyright Notice :

This article only represents the author's point of view.

This article is published under the authorization of the author.

Source:

This article address : Three Roll Mill Application: Lipstick & Carbon Black

Related Suggestion:

Double planetary mixer new type of mixing equipment

Multiple paddle options of Double Planetary Mixer

Double planetary mixer is the first choice for paste materials

Multiple mixing tanks with double planetary mixer

Double planetary mixer for chemical products

Double planetary mixer can be vacuum feeding

Related Products

-

Vacuum Double Planetary Mixer

A Vacuum double planetary mixer is an essential part of any industry to mixing particular material. A double planetary m...

-

Laboratory Double Planetary Mixer

Laboratory double planetary mixer is a kind of non-standardized strong mixing and mixing equipment developed by FLE for ...

-

Hydraulic Lifting High Speed Disperser

The hydraulic lift high speed disperser has the characteristics of simple operation and high flexibility.The hydraulic l...

News

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

- Tricks About Ointment Mill You Wish You ...

- A deep insight into Sand Mill Machine

- What is the difference between dyno mill...

- How To Choose Vertical Bead Mill or Hori...

- What is a three roll mill machine?

- Three Roll Mills: Their mechanism, advan...

- Specification of high speed disperser an...

- high speed disperser machine application

- Faults and Trouble Shooting Methods of H...

- How to operate High-Speed Disperser