-

Equipments

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Or Contact Info

-

Coating

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Adhesives

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Agrochemistry

-

-

Agrochemistry

- Emulsifiable Concentrate

- Suspension Concentrate

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Battery

-

-

Battery

- Battery Slurries

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Cosmetic

-

-

Cosmetic

- Lipstick

- Eyebrow Pencil

- Ointment

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

The use characteristics and skills of the Three roll mill

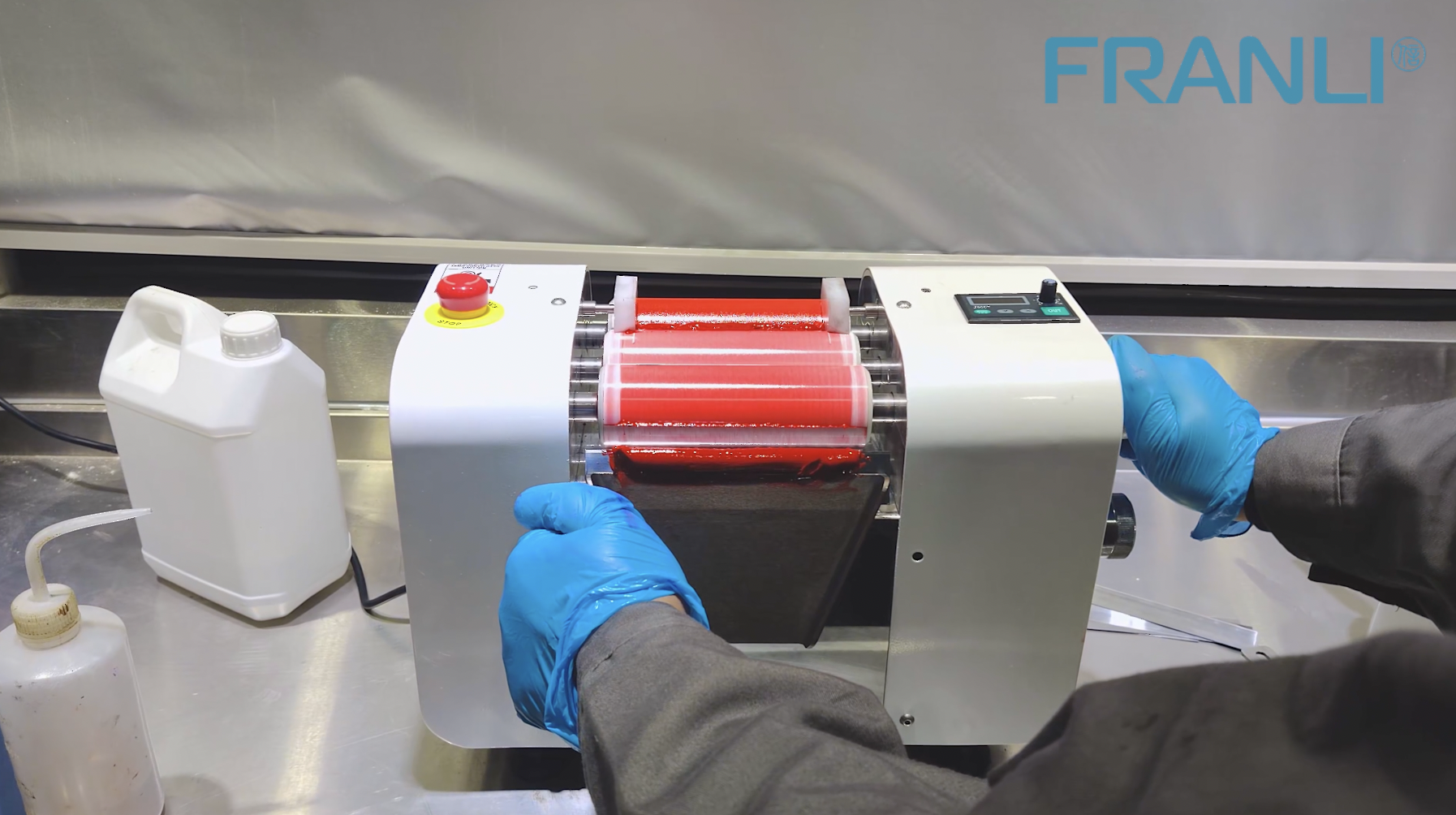

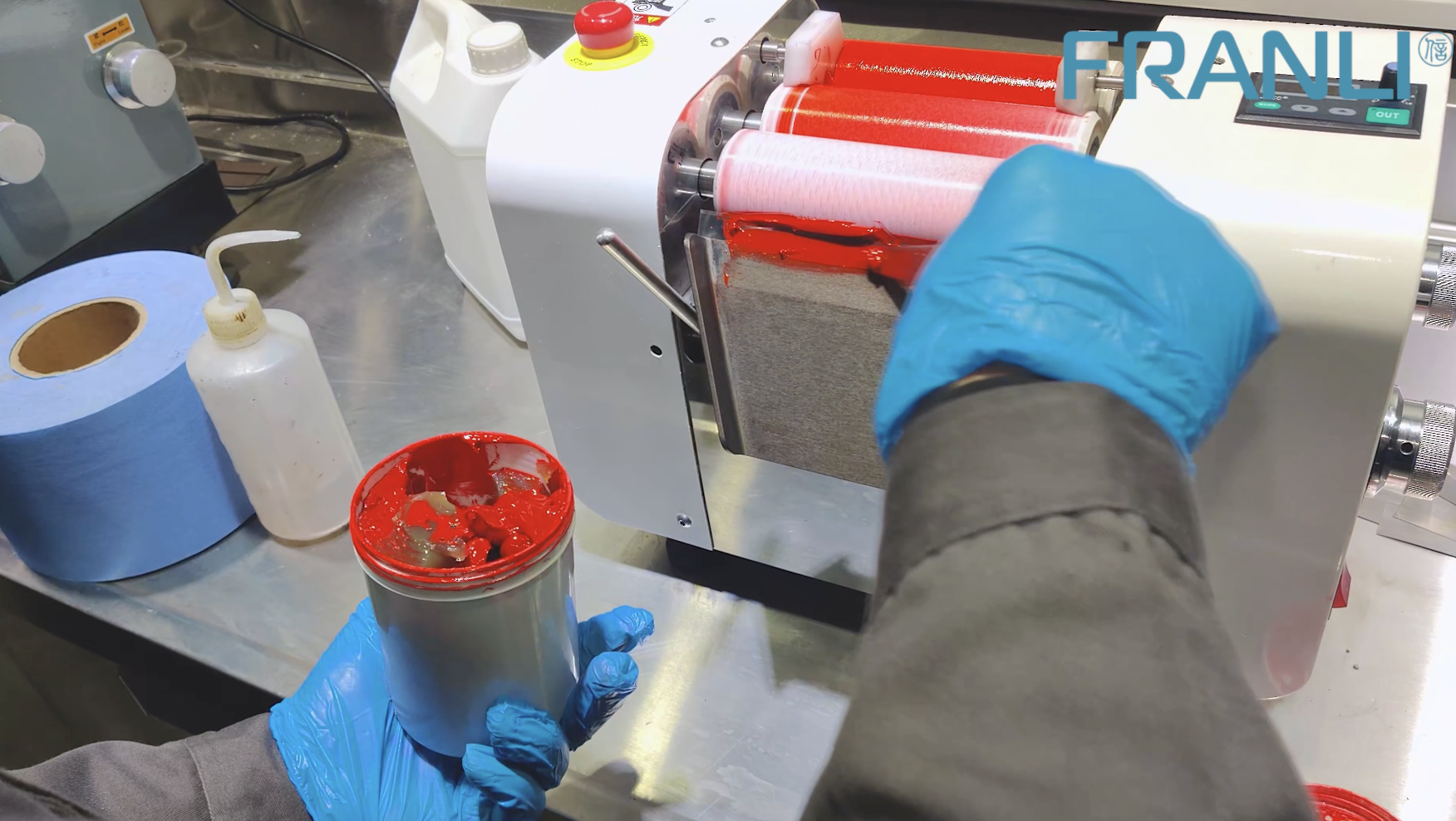

Three roll mill is referred to as a triple roll mill. Three roll mill is the most efficient equipment for grinding and dispersing high viscosity materials. Three roll mills can be divided into laboratory three roll mills and production three roll mills. Both are mainly suitable for the production of paints, inks, pigments, plastics, and other slurries. Its working principle is to achieve the grinding effect through the surface extrusion of three horizontal rollers and friction at different speeds.

|

|

| Lab Three Roll Mill | Hydraulic Three Roll Mill |

What are the features and techniques of using the Three roll mill?

1. Three roll mill has three rollers installed on the iron frame, the center is straight. It can be installed horizontally or slightly inclined. The grinding effect is achieved by squeezing the surface of the three horizontal rollers and friction at different speeds. Steel drums can be hollow and can be cooled with water. Add material between the middle and rear rolls. Since the rotation directions of the three drums are different (the rotation speed increases sequentially from the back to the front), a good grinding effect is produced. After grinding, the material is scraped off by knives mounted in front of the front rollers.

2. When using the Three roll mill, check whether the position and locking of each part are normal. Add lubricating oil according to the marked point, turn on the power, adjust the front and rear handwheels, observe whether the roller system is normal, remove the dirt on the roller surface: wipe with soft paper or clean cotton yarn, loosen the baffle clamp, and adjust the front and rear rollers and the middle roller to 0.5 mm, then start the power supply and let it idle for 1-2 minutes.

3. Three roll mill is mainly used for various high-grade pastes, such as paints, inks, plastics, pigments, cosmetics, electronic pastes, solar silver pastes, aluminum pastes, glass solder pastes, etc. It is especially suitable for the grinding of products with high dispersion viscosity and high particle size required by the centrifugal casting of chilled gold cast iron rolls. The crystal phase is dense, the strength is high, the surface hardness is high, and the wear resistance is good.

The correct way to use the three roll mill

Rotation operation:

1. Open the Three roll mill to check:

(1) Check whether the roller surface of the Three roll mill is clean and whether there is any foreign matter between the rollers.

(2) Check whether the scraper is sharp

(3) Check whether each lubricating part is sufficiently lubricated.

2. Preparations before starting:

(1) Loosen the rollers in turn.

(2) Release the blanking knife.

(3) Slightly loosen the gear tip.

(4) Prepare the slurry tank (must be cleaned)

(5) Open the cooling water valve.

3. Start:

(1) Press the Three roll mill start button to start.

(2) Appropriately press the tip of the gear and immediately load the material (paint)

(3) Rotate the handwheel, adjust the slow roller and the fast roller, move closer to the middle, observe that the roller surfaces are parallel, and adjust the tightness of the roller.

FLE Three roll mill has a leading position in wet grinding equipment. Currently, it has set up agencies in more than 20 countries in the world, and we have a complete and mature after-sales service to relieve users from worries before and after use. If you are still Finding a trusted partner you can contact us directly.

Copyright Notice :

This article only represents the author's point of view.

This article is published under the authorization of the author.

Source:

This article address : The use characteristics and skills of the Three roll mill

Previous:Factory Guidelines for FLE Three Roll Mills

Next:Efficient Kneader|Kneader Manufacturers & Suppliers

Related Suggestion:

Double planetary mixer new type of mixing equipment

Multiple paddle options of Double Planetary Mixer

Double planetary mixer is the first choice for paste materials

Multiple mixing tanks with double planetary mixer

Double planetary mixer for chemical products

Double planetary mixer can be vacuum feeding

Related Products

-

Vacuum Double Planetary Mixer

A Vacuum double planetary mixer is an essential part of any industry to mixing particular material. A double planetary m...

-

Laboratory Double Planetary Mixer

Laboratory double planetary mixer is a kind of non-standardized strong mixing and mixing equipment developed by FLE for ...

-

Hydraulic Lifting High Speed Disperser

The hydraulic lift high speed disperser has the characteristics of simple operation and high flexibility.The hydraulic l...

News

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

- Tricks About Ointment Mill You Wish You ...

- A deep insight into Sand Mill Machine

- What is the difference between dyno mill...

- How To Choose Vertical Bead Mill or Hori...

- What is a three roll mill machine?

- Three Roll Mills: Their mechanism, advan...

- Specification of high speed disperser an...

- high speed disperser machine application

- Faults and Trouble Shooting Methods of H...

- How to operate High-Speed Disperser