-

Equipments

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Or Contact Info

-

Coating

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Adhesives

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Agrochemistry

-

-

Agrochemistry

- Emulsifiable Concentrate

- Suspension Concentrate

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Battery

-

-

Battery

- Battery Slurries

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Cosmetic

-

-

Cosmetic

- Lipstick

- Eyebrow Pencil

- Ointment

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

What is a twin shaft disperser?

The twin shaft disperser (TSD) is an integrated machine that integrates mixing and dispersing. It adds a low-speed mixing function to the original dispersing machine. The low-speed mixing runs in the opposite direction to the high-speed dispersion, so that turbulence can be formed in the dispersion barrel and the material in the dispersion barrel can move. More intense, more uniform dispersion. Moreover, a scraper can be added to the mixing frame to solve the problem of uneven dispersion of high-viscosity materials adhering to the barrel wall. Compared with the original dispersing machine, the concentric double-shaft mixing and dispersing integrated machine has a better and more uniform effect of dispersing materials, and the production time is greatly shortened, which saves time for mass production. The size of the stirring blades and other specifications can be designed and manufactured according to the specific requirements of customers.

The twin shaft disperser (TSD) is an integrated machine that integrates mixing and dispersing. It adds a low-speed mixing function to the original dispersing machine. The low-speed mixing runs in the opposite direction to the high-speed dispersion, so that turbulence can be formed in the dispersion barrel and the material in the dispersion barrel can move. More intense, more uniform dispersion. Moreover, a scraper can be added to the mixing frame to solve the problem of uneven dispersion of high-viscosity materials adhering to the barrel wall. Compared with the original dispersing machine, the concentric double-shaft mixing and dispersing integrated machine has a better and more uniform effect of dispersing materials, and the production time is greatly shortened, which saves time for mass production. The size of the stirring blades and other specifications can be designed and manufactured according to the specific requirements of customers.

This twin shaft disperser also has a fixed type of kettle, and various non-standard requirements for the kettle such as vacuum can be added. Mainly used for large-volume production of high-viscosity materials, integrating slow mixing and high-speed dispersion into one machine (such as architectural coatings, interior, and exterior wall latex paints, medium-thick pastes, real stone paints, etc.).

Principle and characteristics of twin shaft disperser

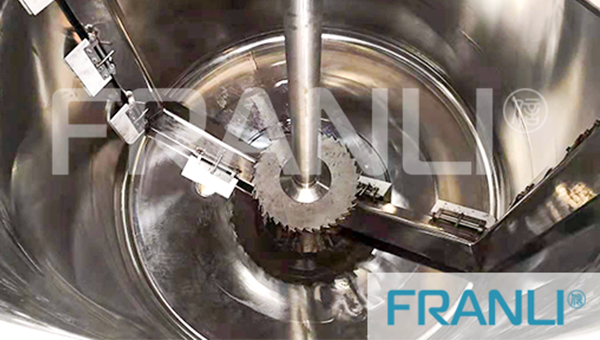

The high-speed rotating shaft of the twin shaft disperser is in the center of the mixing tank, and the serrated dispersing disc has a considerable diameter, so it has a large shear force. In addition, the low-speed frame-shaped mixing paddle flexes the mixing to make the mixing, Mixing, kneading and dispersion performance are greatly improved. This machine is equipped with a vacuuming mechanism to realize vacuum stirring. The machine can also install a jacket on the outer wall of the mixing tank for cooling or heating. According to your requirements, various devices and various measuring instruments can be installed on the twin shaft disperser. For large-capacity mixing, stirring, and dispersing, the barrel of the mixer is a fixed type.

For high-viscosity liquids, due to the rotation of the frame-shaped stirring paddle, a slow circular motion (tangential flow) is formed in the whole container, and the rapid rotation of the high-speed stirring paddle can provide the axial flow (circulating flow). A crisscrossing mass flow is formed in the container. Frame-shaped stirring can also be made into a spiral belt type. When the twin shaft disperser’s low-speed stirring blade rotates, the liquid in the container is pushed upwards, while the high-speed stirring blade makes the liquid flow in the opposite direction, so that the up and down circulation flow forms convective mixing, which improves the stirring effect.

FLE has unique insights in the research and development of twin shaft disperser, and our twin shaft disperser have been sold in more than 20 countries in the world. We not only have a professional after-sales team, but also will launch a larger machine in terms of price. Offer, if you are still looking for a suitable twin shaft dispersing machine manufacturer, do not hesitate to contact us.

Copyright Notice :

This article only represents the author's point of view.

This article is published under the authorization of the author.

Source:

This article address : What is a twin shaft disperser?

Related Suggestion:

Double planetary mixer new type of mixing equipment

Multiple paddle options of Double Planetary Mixer

Double planetary mixer is the first choice for paste materials

Multiple mixing tanks with double planetary mixer

Double planetary mixer for chemical products

Double planetary mixer can be vacuum feeding

Related Products

-

Vacuum Double Planetary Mixer

A Vacuum double planetary mixer is an essential part of any industry to mixing particular material. A double planetary m...

-

Laboratory Double Planetary Mixer

Laboratory double planetary mixer is a kind of non-standardized strong mixing and mixing equipment developed by FLE for ...

-

Hydraulic Lifting High Speed Disperser

The hydraulic lift high speed disperser has the characteristics of simple operation and high flexibility.The hydraulic l...

News

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

- Tricks About Ointment Mill You Wish You ...

- A deep insight into Sand Mill Machine

- What is the difference between dyno mill...

- How To Choose Vertical Bead Mill or Hori...

- What is a three roll mill machine?

- Specification of high speed disperser an...

- Three Roll Mills: Their mechanism, advan...

- high speed disperser machine application

- Faults and Trouble Shooting Methods of H...

- How to operate High-Speed Disperser