-

Equipments

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Or Contact Info

-

Coating

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Adhesives

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Agrochemistry

-

-

Agrochemistry

- Emulsifiable Concentrate

- Suspension Concentrate

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Battery

-

-

Battery

- Battery Slurries

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Cosmetic

-

-

Cosmetic

- Lipstick

- Eyebrow Pencil

- Ointment

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Grinding equipment needed to make cosmetics

Cosmetics belong to the category of fine chemicals. The vast majority of cosmetics production uses compound technology, which has the characteristics of fewer chemical reactions and strict hygiene requirements. The production equipment can be roughly divided into:

(1) Product manufacturing equipment;

(2) Forming, filling, and packaging equipment.

The production operations of cosmetics are generally as follows: powder extraction, grinding, powder product mixing, emulsification, and dispersion, separation, and classification, heating and cooling, sterilization and disinfection, product molding, and packaging cleaning, etc.

Emulsion preparation technology

In the actual production process of emulsion cosmetics, the stability, appearance and physical properties of the product are closely related to the process conditions such as the operating temperature, emulsification time, feeding method, and stirring conditions during production. Therefore, the process conditions are strictly controlled during the production process. It is an important link to ensure product quality.

The commonly used equipment for cream cosmetics mainly includes various types of mixing equipment, homogenization equipment, three roll mills, vacuum degassing equipment, etc.

In the production process of cream cosmetics, the most critical step to ensure quality is emulsification, so emulsification equipment is the most important equipment.

Emulsification equipment

Mixing equipment

Mixing equipment is (mixer) is the most commonly used equipment for cosmetics.

1. Vertical mixer

There are many types of vertical mixers. Among them, the most commonly used vertical mixers are mainly composed of motor wheels, motors, barrels, screws, discharge ports, clearing ports, pulleys, windows, ladders, entrances, electrical boxes, circulation The blanking port, the feeding port, etc. are constituted. The vertical mixer mainly lifts the raw materials from the bottom of the barrel from the center to the top through the rapid rotation of the screw, and then throws them in an umbrella shape and returns to the bottom, so that the raw materials are stirred up and down in the barrel, and a large number of raw materials can be mixed in a short time. The homogeneous mixing is complete.

2. Bedroom mixer

The horizontal stirred tank is usually an axisymmetric structure, and the axis is horizontal parallel to the ground. Its most significant advantage is that it changes the height of the material in the tank, increases the surface area of the liquid surface, and improves the vibration stability of the mixing equipment. Effectively combine the sedimentation balance and mixing of the materials to quickly realize the mixing and emulsification of the materials.

3. Eccentric mixer

The emulsification stirring equipment installed eccentrically in the stirrer is a piece of eccentric stirring equipment, which can usually change the liquid circulation route in the kettle, and can solve the problems of liquid stratification and material sedimentation during the stirring process.

4. Mobile mixer

Mobile stirring equipment is generally composed of a stirrer, a shaft, and a motor, which can complete small-scale stirring, mixing, emulsification, and other processes. The stirrer itself does not have a cylindrical tank structure, so it needs to be used in conjunction with a heating external equipment

This type of mixing equipment has the advantages of portability, flexibility, and simplicity, and is suitable for small-scale laboratory research and production.

The mixing efficiency is related to the design of the paddle of the mixer. According to the different blades, it can be divided into paddle agitator, propeller agitator, turbine agitator. This type of equipment is generally used for premixing the oil phase and the water phase.

Homogeneous emulsification equipment

Commonly used homogeneous emulsification equipment in the cosmetics industry includes high-shear homogenizer, high-pressure homogenizer, colloid mill, centrifugal homogenizer, ultrasonic emulsifier, etc. Among them, the vacuum homogenizer is the most commonly used emulsification equipment.

Vacuum homogenizing emulsifier

It is composed of a sealed vacuum container part and a stirring part. The mixing part consists of a homogeneous mixer and a frame mixer with a scraper. The stirring speed of the homogeneous mixer is mostly 350~3500r/min, which can be steplessly adjusted; the speed of the scraper stirrer is 10~100r/ min, is slow stirring, its function is to promote the heat transfer of the heat transfer surface during heating and cooling, so that the temperature in the container is uniform, and it has good thermal efficiency.

The front end of the scraper agitator is equipped with a scraper made of polyvinyl fluoride and cyclobutadiene. Due to the hydraulic pressure, it contacts the inner wall of the container, effectively scraping and transferring materials from the inner wall to accelerate the effect of heat exchange.

The vacuum homogenizing emulsifier is also equipped with a series of auxiliary facilities, including heating and cooling interlayers and insulation layers, as well as various measuring instruments such as thermometers, viscosity agents, tachometers, vacuum gauges, and material flow sensors.

The advantages of vacuum homogenizing emulsifier are:

(1) The air bubble content of the emulsified body can be reduced to a minimum, and the surface smoothness of the emulsified body can be increased.

(2) As the stirring and emulsification are carried out in a vacuum state, the materials will no longer be lost due to evaporation, and the contact between the emulsified body and the air is reduced and avoided, the contamination of the product by bacteria is reduced, and the deterioration of the product will not be caused by oxidation.

(3) Under vacuum conditions, the speed of the stirrer is accelerated, which improves the emulsification efficiency.

Other mixing equipment

1. Three roll mill

The three roll mill is widely used in the wet grinding of raw materials in the fine chemical industry such as paint, ink, ink, coating, plastic, rubber, medicine, food, cosmetics, etc. It has multiple functions such as crushing, dispersing, emulsifying, homogenizing, and toning.

In the cosmetics manufacturing process, the three-roll grinder is a widely used grinding equipment, especially in the production of cold cream, lipstick, liquid foundation, and other products.

The three roll mill is composed of body, discharge plate, cooling system, rolls, baffle plate, electrical switch or electrical control system, hand wheel, transmission system, and other components. Among them, the most critical component is installed in a cast-iron frame. Three rolls with different rotation speeds are made of stainless steel or granite. Both ends of the roll shaft are equipped with large and small gears for speed change.

For different types of products and different requirements for the fineness of the paste, the gap between the front and rear rolls and the middle roll can be adjusted according to the actual requirements of the production quality.

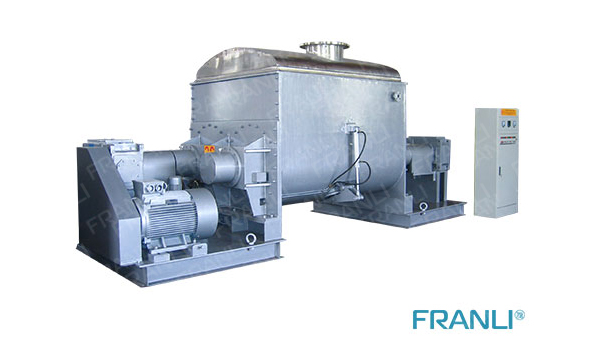

2. Kneader

It not only has the function of mixing and stirring, but also has the comprehensive effect of squeezing, shearing, and folding force on the material. Therefore, the blades of the kneader are extraordinarily strong and can withstand huge forces. The shell of the container also has enough strength and stiffness. The kneader is generally a horizontal structure with two parallel blades. All parts in contact with the material, such as the mixing blade, the inner wall of the mixing tank, and the wallboard, are made of stainless steel, and they are all corrosion-resistant.

Generally, the rotation speed of the two blades of the kneader is different, the speed range is 30-60r/min, and the speed ratio range is 1.0-1.9, which can be adjusted appropriately according to actual requirements during operation.

Filling equipment

Liquid filling equipment

1. Atmospheric filling machine

The atmospheric liquid filling machine is a simple type of filling equipment that relies on the weight of the liquid to fill under normal pressure.

This type of filling machine is divided into two types: timing filling and constant volume filling. It is suitable for filling low-viscosity and gas-free liquids such as perfume, lotion, toner, toilet water, etc. The most notable features of this type of filling machine are simple principle, low equipment cost, and simple maintenance; but the quantitative method of atmospheric liquid filling machine is relatively simple, and the filling loss is large. For some high-cost cosmetic products or high viscosity, The emulsion is not applicable.

2.Pressure filling machine

Pneumatic cosmetics are a special design of cosmetics. The container is a pressure-resistant metal, plastic, or glass body with an air valve system. Such cosmetics commonly include hair cosmetics, antiperspirant and deodorant cosmetics, perfume, shaving cream, facial cleanser, spray water, and so on.

The working process is divided into three stages: filling, sealing, and inflating.

The liquid filling metering cylinder and the liquid filling head are responsible for quantitative liquid filling, cover, and press rolling, and pneumatic components are responsible for the fluid whose boiling point is below room temperature-propellant (nitrogen, trichlorofluoromethane, dichlorodifluoromethane, etc. are mostly used in cosmetics) ) Press into the bottle under high pressure and squeeze the air out of the spray can.

3. Paste and viscous emulsion canning equipment

The most commonly used method for filling cream products is the mechanical pressure method

The filling equipment adopting the mechanical pressure method mainly includes piston type, scraper pump type, and gear pump type. The piston-type is currently a type of filling equipment commonly used in the cosmetics industry.

Copyright Notice :

This article only represents the author's point of view.

This article is published under the authorization of the author.

Source:

This article address : Grinding equipment needed to make cosmetics

Related Suggestion:

Double planetary mixer new type of mixing equipment

Multiple paddle options of Double Planetary Mixer

Double planetary mixer is the first choice for paste materials

Multiple mixing tanks with double planetary mixer

Double planetary mixer for chemical products

Double planetary mixer can be vacuum feeding

Related Products

-

Vacuum Double Planetary Mixer

A Vacuum double planetary mixer is an essential part of any industry to mixing particular material. A double planetary m...

-

Laboratory Double Planetary Mixer

Laboratory double planetary mixer is a kind of non-standardized strong mixing and mixing equipment developed by FLE for ...

-

Hydraulic Lifting High Speed Disperser

The hydraulic lift high speed disperser has the characteristics of simple operation and high flexibility.The hydraulic l...

News

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

- Tricks About Ointment Mill You Wish You ...

- A deep insight into Sand Mill Machine

- What is the difference between dyno mill...

- How To Choose Vertical Bead Mill or Hori...

- What is a three roll mill machine?

- Specification of high speed disperser an...

- Three Roll Mills: Their mechanism, advan...

- high speed disperser machine application

- Faults and Trouble Shooting Methods of H...

- How to operate High-Speed Disperser