-

Equipments

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Or Contact Info

-

Coating

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Adhesives

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Agrochemistry

-

-

Agrochemistry

- Emulsifiable Concentrate

- Suspension Concentrate

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Battery

-

-

Battery

- Battery Slurries

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Cosmetic

-

-

Cosmetic

- Lipstick

- Eyebrow Pencil

- Ointment

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

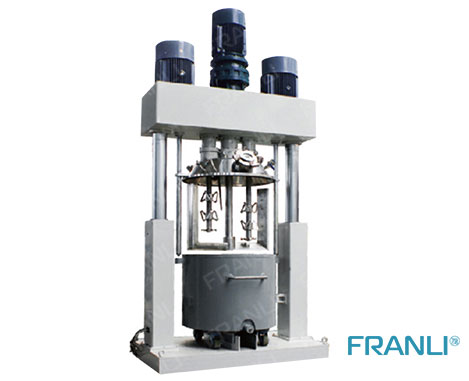

Multi-Shaft Mixer

-

Plateform Multi-Shaft Mixer

This platform multi-shaft mixers are suitable for high-viscosity or high-dispersion mixing equipment...

-

Triple Shaft Mixer

Hydraulic lifting triple shaft mixer (dispersion, stirring, emulsification), this equipment is a pro...

-

Multi-Shaft Mixer

Muti shaft mixer is widely used in middle and high viscosity materials. It applies to materials with...

FLE customized different kinds of multi-shaft mixers for more than 300+ customers. This kind of machine works in the coating industry, medicine industry, cosmetic industry, and other high technology chemical industries.

How many kinds of shaft mixers for a multi-shaft mixer?

FLE offers the design of a high-speed disperser, three wing anchor, homogenizer for emulsification, and high viscosity mixer with scrapper. The tank is designed by the jacket, coil, or half coil. You can connect with a heating system or cooling system according to your material features.

What are the advantages of the multi-shaft mixer?

Hydraulic control lifting, totally grinding, mixing, dispersing high viscosity material. VFD controls the speed of high speed disperser. Other two motors with reducers. We choose the brand's main parts, such as WN/SIEMENS motor, NORD/SEW reducer, Schneider electricity, and the stainless steel polished as mirror surface inside of the tank. Our FLE machine has no blind space, totally mixing and dispersing, and also easily discharging.

How much viscosity material is suitable for this type of multi-shaft mixer?

The range of viscosity is 10,000cps - 2,000,000cps, cream mixing, vulcanization, dispersing, milling, and polymerization processing. Silicone sealant, PU sealant, mechanical sealant, liquid silicone, PTV, Electronic sealant, ink, pigment, dye, electronic paste, resin, plastics, toothpaste, etc.

FLE has two types of the multi-shaft mixer, one is standing floor hydraulic lifting, this type of multi-shaft mixer is easy to move the tanks on the floor. You may need to purchase the hydraulic discharging machine with the filling machine together. Also has a tank with lugs to support the floor. This tank is fixed, and discharging by itself weight, or discharging by the pump. Which is most suitable for your factory, you may discuss with us before ordering this multi-shaft mixer.

What key points you should focus on?

1) the tank quality is important, if not round totally, which tank can not discharge well, can not vacuum, or mix well. Some customers want to save the cost, some factories save cost on the tank, but this simple tank, while a key point for high viscosity mixer. Pls don't save small costs, and pay huge for future machines.

2) Heating system by steam, some asked oil heating, while which depends on the features of materials, if you want to cool and heating both on one system, pls go to choose the steam by water also cooling by the chiller.

3) Also has some other key points that you need to focus on, welcome to connect with us, we would like to share our experience with you.

Production Line

-

PCB INK Machine line

FLE supplies all equipments for the production of PCB inks, from the powder feeding station to the filling part.

-

Offset Ink, UV Ink machine line

The FLE engineering company, offer the full set of UV INK Production Line, we can make the full drawing according with your factory size, fo...

-

Offset Ink machine line

FLE is specialized in offset ink full line production for 20+ years. Helped customer save the cost, save the man power, also save the space....

Equipments

News

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

Bead Mill

- SMP Agitator bead mill

- Zirconia beads for sale|Zirconia beads price

- Wet Bead Mill|Bead Mill For Sale

- Sand Mill Machine|Sand Mill For Paint

- Sand Mill|Wet Grinding Equipment Manufacturer

- Bead Mill Machine

- Vertical sand mill

- Bead mill for paint

- Horizontal sand mill

- Turbine bead mill

- Lab bead mill

- Nano Mill

- Vertical Bead Mill

- Bag Filter

- Zirconia Beads

- Pearl Mill

- Dyno mills

- Horizontal Bead Mill

- Agitator bead mill

- Sand Mill

-

Three Roll Mill

-

Twin Shaft Disperser

-

High Speed Disperser

-

Basket Mill

-

High Shear Mixer

-

Double Planetary Mixer

-

Chemical Reactor

-

Kneader

-

Filling Machine

-

Multi-Shaft Mixer

-

Attritor Mill

-

Ribbon Blender

-

Pneumatic Mixer

-

Static Mixer

-

Nitrogen Generator

-

Production Line

- Tricks About Ointment Mill You Wish You ...

- A deep insight into Sand Mill Machine

- What is the difference between dyno mill...

- How To Choose Vertical Bead Mill or Hori...

- What is a three roll mill machine?

- Specification of high speed disperser an...

- Three Roll Mills: Their mechanism, advan...

- high speed disperser machine application

- Faults and Trouble Shooting Methods of H...

- How to operate High-Speed Disperser