-

Equipments

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Or Contact Info

-

Coating

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Adhesives

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Agrochemistry

-

-

Agrochemistry

- Emulsifiable Concentrate

- Suspension Concentrate

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Battery

-

-

Battery

- Battery Slurries

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Cosmetic

-

-

Cosmetic

- Lipstick

- Eyebrow Pencil

- Ointment

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

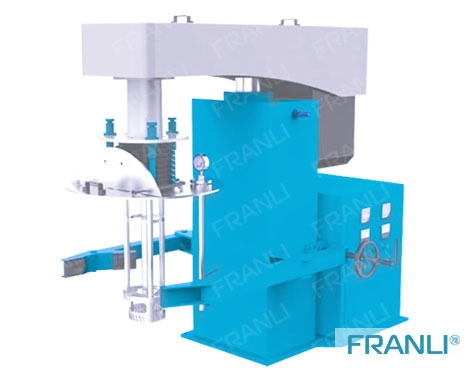

High Shear Mixer

High Shear Mixer is to disperse one or more phases into another continuous phase through efficient, fast, uniform and other processes, and under normal circumstances each phase is insoluble. Because of the high rotor high-speed rotation of the tangent velocity and kinetic energy of high frequency mechanical effect brings strong, make the material in the narrow gap, rotor fierce mechanical and hydraulic shear, centrifugal extrusion, tearing and turbulent liquid layer friction, lighting strike etc inductive effect, so that the miscibility of the solid phase, liquid phase and gas phase in the corresponding mature technology and with a moderate amount of additive effect, Disperse and emulsify evenly and finely in an instant, and get stable and high-quality products after high frequency cycles.

High Shear Mixer is to disperse one or more phases into another continuous phase through efficient, fast, uniform and other processes, and under normal circumstances each phase is insoluble. Because of the high rotor high-speed rotation of the tangent velocity and kinetic energy of high frequency mechanical effect brings strong, make the material in the narrow gap, rotor fierce mechanical and hydraulic shear, centrifugal extrusion, tearing and turbulent liquid layer friction, lighting strike etc inductive effect, so that the miscibility of the solid phase, liquid phase and gas phase in the corresponding mature technology and with a moderate amount of additive effect, Disperse and emulsify evenly and finely in an instant, and get stable and high-quality products after high frequency cycles.

High Shear Mixer Features

The main performance characteristics of high shear emulsifier:

1. High Shear Mixer, also known as centrifugal homogenizer, is especially suitable for the material before the process.

2. High Shear Mixer with large capacity, small energy consumption, suitable for industrial continuous production.

3. The material processed by High Shear Mixer has the characteristics of narrow particle dispersion scale and good uniformity.

4. High Shear Mixer production efficiency, time saving, labor saving, low energy consumption, high production efficiency.

5. The assembly and disassembly of the high shear emulsifier are simple, easy to clean, and can meet the needs of CIP cleaning in different occasions.

6. High Shear Mixer has certain self-suction and low lift transport function.

7. High Shear Mixer has no dead Angle, the material is 100% dispersed emulsification and other characteristics.

8. The High Shear Mixer has low noise, stable operation and convenient protection.

High Shear Mixer basic functions:

Shearing

(1) The material is instantly subjected to strong mechanical shear action through the outer diameter of the rotor and the inner diameter of the stator.

(2) Complex and intense fluid movement drives particles to collide with each other, as well as particles to collide with rotating stator, thus forming a hydrodynamic shear effect that cannot be underestimated.

Grinding

The material is abraded and torn between the outer diameter of the rotor and the inner diameter of the stator.

Mixing with Pump

Through the rotor groove and blade rotation to drive fluid centrifugal movement, pumping effect. Rotor groove and stator groove and High Shear Mixer blades agitation, mixing effect.

Working principle:

A High Shear Mixer is an efficient, rapid and uniform distribution of one or more phases into another continuous phase, which is normally insoluble. Due to their high rotor generated by high speed rotating tangential velocity and high frequency mechanical effect, the strong momentum of the material in the narrow gap, rotor by strong mechanical and hydraulic shear, centrifugal extrusion, liquid such as friction, impact and tear turbulent layer combination, so that the miscibility of the solid phase, liquid phase and gas phase in the corresponding mature technology and a moderate amount of additives, The High Shear Mixer is dispersed evenly and finely in an instant, and the stable and high-quality products are finally obtained through high frequency cycle.

We are the manufacturer of high shear mixer, high shear disperser,vacuum mixer homogenizer. We are design and produce high shear mixer according with customer viscosity, capacity, temperature, also we need know the pressure if in tank. One is installed in tank,which is vertical type high shear mixer; another horizontal one is out of tank. We has singal grade, 3 grade solid-powder inline high shear mixer.

Application

Related Products

More

-

Vacuum Double Planetary Mixer

A Vacuum double planetary mixer is an essential part of any industry to mixing particular material. A double planetary m...

-

Laboratory Double Planetary Mixer

Laboratory double planetary mixer is a kind of non-standardized strong mixing and mixing equipment developed by FLE for ...

-

Hydraulic Lifting High Speed Disperser

The hydraulic lift high speed disperser has the characteristics of simple operation and high flexibility.The hydraulic l...

-

SMP Agitator bead mill

This SMP Agitator bead mill is used in the paint, ink, and coating industries to ready the equal-sized particles of a pa...

-

TRS-Three Roll Mill For Lipstick

TRS Three roll mill is widely used in milling paste material including paint, inks, China ink, pigment, coatings, food, ...

-

Basket Mill Machine

What is a FLE Basket Mill? Our basket mill combines dispersing and grinding into a single machine that is suitable for g...

News

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

Bead Mill

- SMP Agitator bead mill

- Zirconia beads for sale|Zirconia beads price

- Wet Bead Mill|Bead Mill For Sale

- Sand Mill Machine|Sand Mill For Paint

- Sand Mill|Wet Grinding Equipment Manufacturer

- Bead Mill Machine

- Vertical sand mill

- Bead mill for paint

- Horizontal sand mill

- Turbine bead mill

- Lab bead mill

- Nano Mill

- Vertical Bead Mill

- Bag Filter

- Zirconia Beads

- Pearl Mill

- Dyno mills

- Horizontal Bead Mill

- Agitator bead mill

- Sand Mill

-

Three Roll Mill

-

Twin Shaft Disperser

-

High Speed Disperser

-

Basket Mill

-

High Shear Mixer

-

Double Planetary Mixer

-

Chemical Reactor

-

Kneader

-

Filling Machine

-

Multi-Shaft Mixer

-

Attritor Mill

-

Ribbon Blender

-

Pneumatic Mixer

-

Static Mixer

-

Nitrogen Generator

-

Production Line

- Tricks About Ointment Mill You Wish You ...

- A deep insight into Sand Mill Machine

- What is the difference between dyno mill...

- How To Choose Vertical Bead Mill or Hori...

- What is a three roll mill machine?

- Specification of high speed disperser an...

- Three Roll Mills: Their mechanism, advan...

- high speed disperser machine application

- Faults and Trouble Shooting Methods of H...

- How to operate High-Speed Disperser