-

Equipments

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Or Contact Info

-

Coating

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Adhesives

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Agrochemistry

-

-

Agrochemistry

- Emulsifiable Concentrate

- Suspension Concentrate

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Battery

-

-

Battery

- Battery Slurries

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Cosmetic

-

-

Cosmetic

- Lipstick

- Eyebrow Pencil

- Ointment

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

High Shear Mixer

-

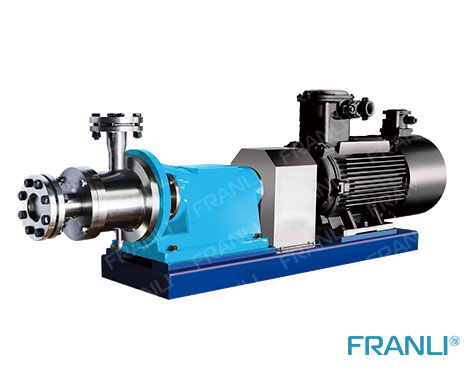

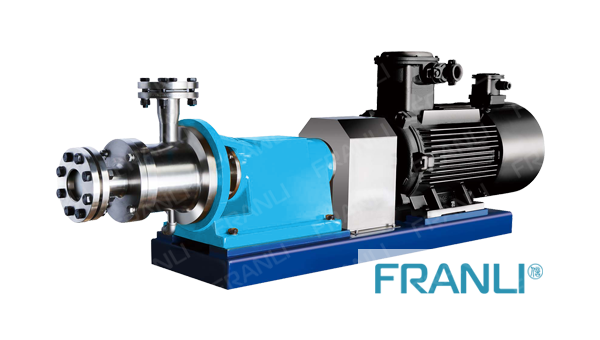

Inline Emulsifier

The inline emulsifier is composed of three sets of stators (two layers, four layers, and six layers)...

-

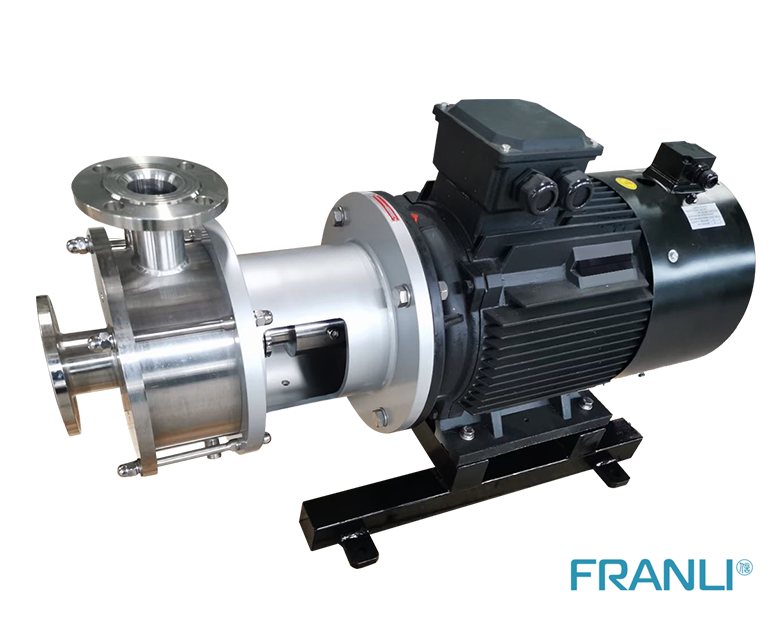

Inline Homogenizer

The Inline homogenizer is mainly used for mixing and homogenizing materials, dispersing, and emulsif...

-

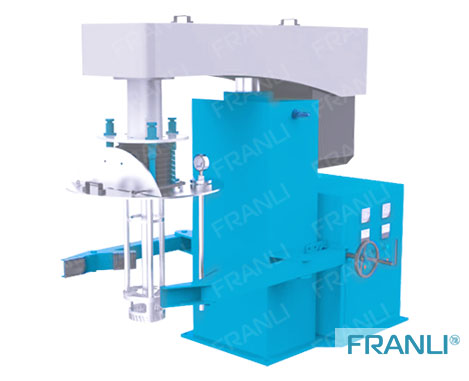

High Shear Mixer

High Shear Mixer is to disperse one or more phases into another continuous phase through efficient, ...

-

High Shear Emulsifier

The high shear mixer is widely used in the experimental fields of liquid mixing, emulsification, liq...

The high shear mixer is widely used in the experimental fields of liquid mixing, emulsification, liquid/solid powder dispersion, and slurrying in biology, physics, chemistry, cosmetics, health care products, food, paint, coatings, and chemicals. It is ideal laboratory equipment for scientific research, product development, quality control, and production process applications in scientific research institutions, colleges and universities, health and epidemic prevention, product manufacturing, and pharmaceutical and medical units.

The dispersion process of the high shear mixer is based on the cutting principle of the rotor and the stator. The experimental equipment is driven by a high-speed motor to drive the shearing and emulsifying working head, which promotes the rotor to make a high-speed circular motion. The high-speed rotating rotor and the precision stator form high-frequency, strong circumferential tangential velocity, angular velocity, and other comprehensive kinetic energy, which encourages the experimental materials to be sucked into the rotor area from the bottom of the experimental container, and the stator hole under the action of huge centrifugal force throw out. The stator and rotor form strong, reciprocating hydraulic shear, friction, centrifugal extrusion, and fluid collision in a reasonably narrow gap. The experimental materials cyclically reciprocate in the container, and withstand tens of thousands of times per minute of shearing, tearing, impact and mixing, to achieve the effect of shearing and emulsification, and the efficiency of high shear mixer is about a thousand times higher than that of ordinary mixing.

The high-shear mixer is a multi-functional integrated complex emulsification equipment. Because of its multi-functionality, it must be operated by the manufacturer before using it.

The components of our equipment operation are the mixing system of the main emulsification tank, the homogenization system, the lifting system of the main tank, the mixing system of the water-oil tank, and the vacuum system. The equipment can be controlled according to the buttons on the control panel, including lighting and extinguishing the lights, controlling the mixing operation of the mixing bowl, homogenizing mixing operation of the mixing bowl, mixing operation of the water and oil boiler, controlling the operation of the vacuum system and the main Heating of pot and water and oil pot. The various controls of the equipment are carried out on the control panel.

Daily operation guide for high shear mixer

①Turn on the power →②Feeding in the oil-water pot →③Close the lid of the oil-water pot →④heat and stir the oil-water pot →⑤Close the lid of the homogenizer pot, close other valves on the lid, and open the vacuum valve to vacuum (suction) →⑥Homogenizer pot Heating (adjustable temperature)→⑦Homogeneous mixing and emulsification of the poor material (time is up) stop heating→⑧open the discharge valve again to discharge the material→⑨(after cleaning, the lid can be lifted, dumped, drained and closed)→⑩circulation.

Production Line

-

PCB INK Machine line

FLE supplies all equipments for the production of PCB inks, from the powder feeding station to the filling part.

-

Offset Ink, UV Ink machine line

The FLE engineering company, offer the full set of UV INK Production Line, we can make the full drawing according with your factory size, fo...

-

Offset Ink machine line

FLE is specialized in offset ink full line production for 20+ years. Helped customer save the cost, save the man power, also save the space....

Equipments

News

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

Bead Mill

- SMP Agitator bead mill

- Zirconia beads for sale|Zirconia beads price

- Wet Bead Mill|Bead Mill For Sale

- Sand Mill Machine|Sand Mill For Paint

- Sand Mill|Wet Grinding Equipment Manufacturer

- Bead Mill Machine

- Vertical sand mill

- Bead mill for paint

- Horizontal sand mill

- Turbine bead mill

- Lab bead mill

- Nano Mill

- Vertical Bead Mill

- Bag Filter

- Zirconia Beads

- Pearl Mill

- Dyno mills

- Horizontal Bead Mill

- Agitator bead mill

- Sand Mill

-

Three Roll Mill

-

Twin Shaft Disperser

-

High Speed Disperser

-

Basket Mill

-

High Shear Mixer

-

Double Planetary Mixer

-

Chemical Reactor

-

Kneader

-

Filling Machine

-

Multi-Shaft Mixer

-

Attritor Mill

-

Ribbon Blender

-

Pneumatic Mixer

-

Static Mixer

-

Nitrogen Generator

-

Production Line

- Tricks About Ointment Mill You Wish You ...

- A deep insight into Sand Mill Machine

- What is the difference between dyno mill...

- How To Choose Vertical Bead Mill or Hori...

- What is a three roll mill machine?

- Specification of high speed disperser an...

- Three Roll Mills: Their mechanism, advan...

- high speed disperser machine application

- Faults and Trouble Shooting Methods of H...

- How to operate High-Speed Disperser