-

Equipments

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Or Contact Info

-

Coating

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Adhesives

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Agrochemistry

-

-

Agrochemistry

- Emulsifiable Concentrate

- Suspension Concentrate

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Battery

-

-

Battery

- Battery Slurries

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Cosmetic

-

-

Cosmetic

- Lipstick

- Eyebrow Pencil

- Ointment

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

High speed dissolver

The high speed dissolvers currently sold by FLE are divided into two types: vertical type and platform type, one is mobile type and the other is fixed type. The structure of the high-speed disperser can be divided into hydraulic lifting, rotating, driving, stirring shaft, fuel tank, electric cabinet, etc.

The high speed dissolvers currently sold by FLE are divided into two types: vertical type and platform type, one is mobile type and the other is fixed type. The structure of the high-speed disperser can be divided into hydraulic lifting, rotating, driving, stirring shaft, fuel tank, electric cabinet, etc.

A high speed dissolver is one high-efficiency equipment that can mix, dissolve and disperse various liquid mixtures. Its main features are as follows: there are two (medium speed and high-speed---Type GFJ-7 and GFJ-11) or three (low-speed, medium-speed, and high-speed---Type GFJ-22 and GFJ-40) rotation speeds for mixing shaft, with low-speed and medium speed for mixing and dissolving and high-speed for dispersing. By the action of high-rotation of the blade, materials will turn violently in the vessel and be bumped and cut by blades, the material will be destroyed, and then the aim of quickly dispersing, evenly mixing, and quickening dissolving can be realized. The machine is widely used in the fabrication of fine chemical products, such as paint, dye, printing ink, and adhesive composition.

The high speed dissolver produced in our company can be divided into two types: Type A is the standing type which is applicable for a movable vessel; Type B is the platform type which is applicable for a fixed vessel on line flow. One machine can be equipped with 2-4 vessels for alternative use and handled easily. Meanwhile, we also design mixing or dispersion equipment with a high power of 55kw~132kw to cater to our customers.

Structure and principle of high speed dissolver

The structure of a high speed dissolver can be divided into hydraulic lifting, rotating, driving, mixing shaft, oil box, and electric cabinet.

1. Hydraulic lifting part

Working principle

It is composed of a plunger and hydro cylinder. Wheel box is lifted by hydraulic oil of gear pump in oil box and will descend by oil drainage for its dead-weight.

Rotating part

2. Working principle

The connection of the tank and wheel box is blocked off by ball bearings and locked tightly by compression ring, friction disk, and driving handle. When the driving handle is loosened, the wheel box will turn at an angle of 360o.

3. Driving part

Working principle

The driven wheel 2 is driven to rotate by driving wheel 6 with Belt 5 in double-speed or three-speed motor 16, then the machine is driven to operate.

4. Mixing shaft

Working principle

The dispersing shaft is supported by a rolling bearing with dispersing disk equipped at the bottom. The power is sent from the driving part to mix, dissolve and disperse the material.

5. Electric control box

It is composed of electrical elements, press buttons, and boxes. The box cover and box door are attached with Electrical Diagram or circuit diagram.

We could also manufacture customization mixers in accordance with customers’ orientation.

video

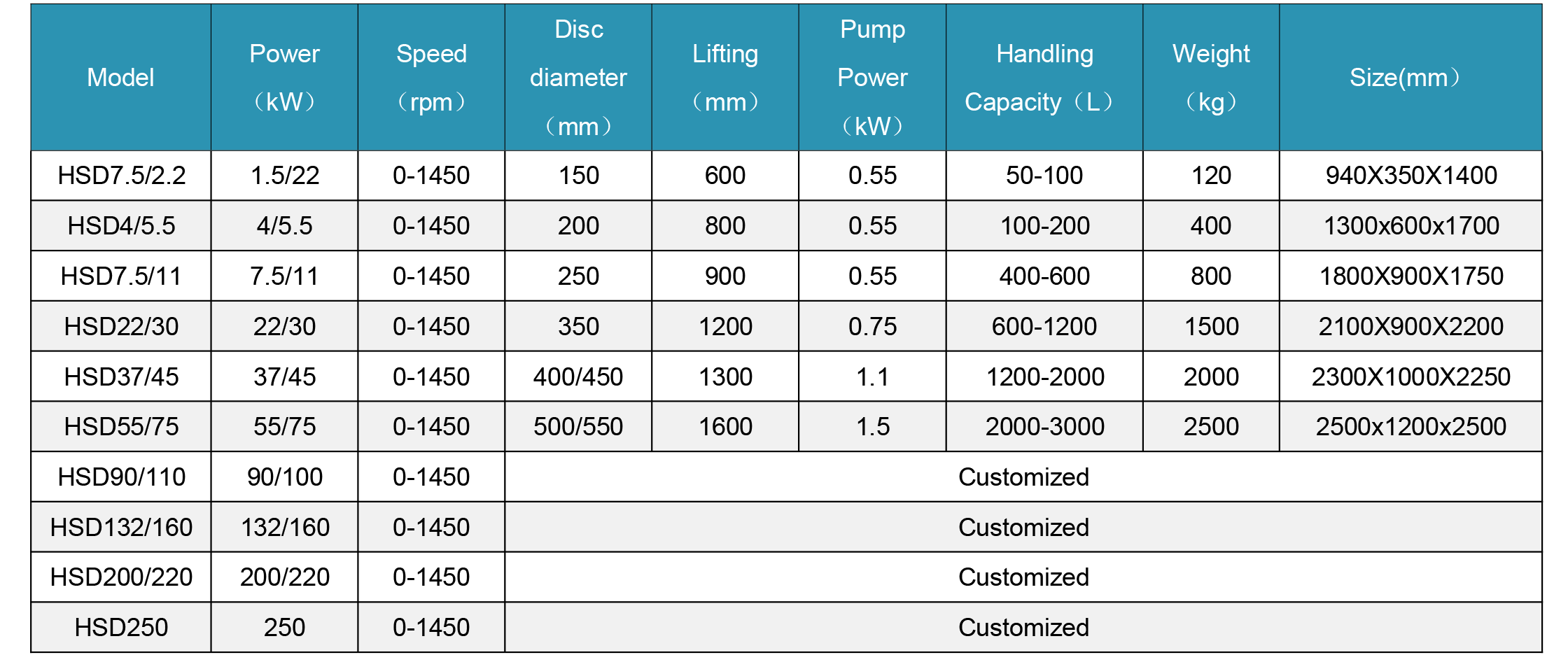

Main Technical Parameters

Application

Related Products

More

-

Vacuum Double Planetary Mixer

A Vacuum double planetary mixer is an essential part of any industry to mixing particular material. A double planetary m...

-

Laboratory Double Planetary Mixer

Laboratory double planetary mixer is a kind of non-standardized strong mixing and mixing equipment developed by FLE for ...

-

Hydraulic Lifting High Speed Disperser

The hydraulic lift high speed disperser has the characteristics of simple operation and high flexibility.The hydraulic l...

-

SMP Agitator bead mill

This SMP Agitator bead mill is used in the paint, ink, and coating industries to ready the equal-sized particles of a pa...

-

TRS-Three Roll Mill For Lipstick

TRS Three roll mill is widely used in milling paste material including paint, inks, China ink, pigment, coatings, food, ...

-

Basket Mill Machine

What is a FLE Basket Mill? Our basket mill combines dispersing and grinding into a single machine that is suitable for g...

News

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

Bead Mill

- SMP Agitator bead mill

- Zirconia beads for sale|Zirconia beads price

- Wet Bead Mill|Bead Mill For Sale

- Sand Mill Machine|Sand Mill For Paint

- Sand Mill|Wet Grinding Equipment Manufacturer

- Bead Mill Machine

- Vertical sand mill

- Bead mill for paint

- Horizontal sand mill

- Turbine bead mill

- Lab bead mill

- Nano Mill

- Vertical Bead Mill

- Bag Filter

- Zirconia Beads

- Pearl Mill

- Dyno mills

- Horizontal Bead Mill

- Agitator bead mill

- Sand Mill

-

Three Roll Mill

-

Twin Shaft Disperser

-

High Speed Disperser

-

Basket Mill

-

High Shear Mixer

-

Double Planetary Mixer

-

Chemical Reactor

-

Kneader

-

Filling Machine

-

Multi-Shaft Mixer

-

Attritor Mill

-

Ribbon Blender

-

Pneumatic Mixer

-

Static Mixer

-

Nitrogen Generator

-

Production Line

- Tricks About Ointment Mill You Wish You ...

- A deep insight into Sand Mill Machine

- What is the difference between dyno mill...

- How To Choose Vertical Bead Mill or Hori...

- What is a three roll mill machine?

- Three Roll Mills: Their mechanism, advan...

- Specification of high speed disperser an...

- high speed disperser machine application

- Faults and Trouble Shooting Methods of H...

- How to operate High-Speed Disperser