-

Equipments

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Or Contact Info

-

Coating

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Adhesives

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Agrochemistry

-

-

Agrochemistry

- Emulsifiable Concentrate

- Suspension Concentrate

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Battery

-

-

Battery

- Battery Slurries

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Cosmetic

-

-

Cosmetic

- Lipstick

- Eyebrow Pencil

- Ointment

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

High Speed Disperser

-

Hydraulic Lifting High Speed Disperser

The hydraulic lift high speed disperser has the characteristics of simple operation and high flexibi...

-

High speed dissolver

High speed dissolver for sale: FLE high speed dissolver is one high-efficiency equipment that can mi...

-

Laboratory high speed disperser

The laboratory high speed disperser can realize multiple functions in one machine, and perfectly rea...

-

FLE High speed disperser

FLE high-speed disperser is widely used in coatings, paints, dyes, inks, latex paints, adhesives, pa...

-

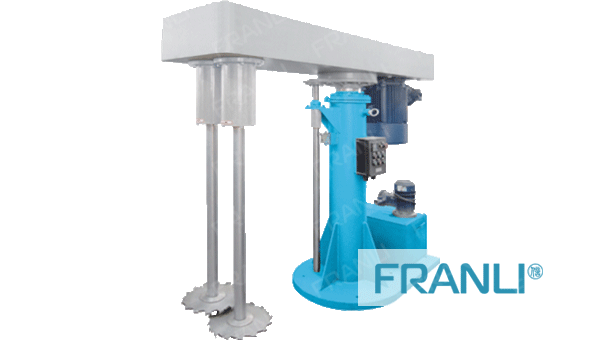

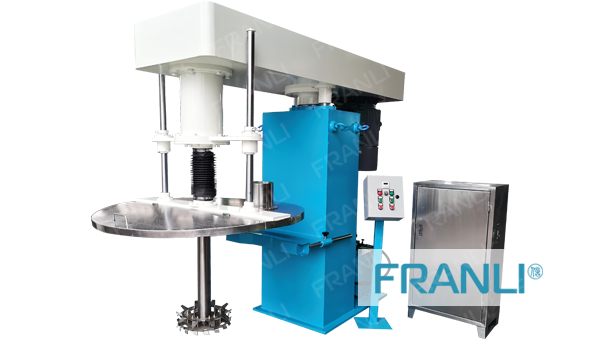

Dispersion Machine

This HSD-D Dispersion Machine with two shafts for mixing and dispersing materials to reach higher ef...

-

Plateform Type High Speed Disperser

Platform type high-speed disperser is mainly used for high production material. Normally the high-sp...

-

Vacuum Disperser

The function of a vacuum disperser reduces bubbles and solvent volatilization, faster material defoa...

-

High Speed Disperser

Architectural waterproof coating production equipment The preparation process of the high-speed disp...

FLE is a professional manufacturer of high-speed dispersers for more than 20 years, we export high-speed dispersers all over the world.

Shaft shake range within 7-8 Si, dispersing has two types, one disc and two discs on the shaft. Hydraulic lifting up head of high-speed disperser. We have motor brand options, such as SIEMENS, ABB or DAZHONG, etc. VFD is a 580 model ABB.

FLE professionally produces one shaft high-speed disperser, twin shaft disperser, and vacuum system mixer, also we offer platform type high-speed disperser with tanks.

Welcome to ask for detailed drawings!

Dispersion Machine

We produce a high-speed disperser according to the industrial standard, FLE HSD’s frame is bigger than the marketing machine, the blade is double layers, hydraulic part is an engineering oil tank, which more stable lifting up and down. The operation box for Water-based material is stainless steel, also has ex-proof operation for solvent based material.

Vacuum Disperser

We have many kinds of dispersers.

Such as Twin Shaft Disperser, Middle and high flowing viscosity material, which twin shaft disperser (TSD) is the best choice. SKF bearing, stable disperser. Frame mixer with Teflon scraper. Which machine has foot standing twin shaft disperser, also platform twin shaft disperser?

High-Speed Disperser

Vacuum type High-Speed Disperser, Which helps you to reduce foaming and solvent evaporation. Vacuum cover fixed on the shaft, with sight glass, with ex-proof light, etc. The vacuum degree is below 0.07mpa. The sealing mouth is soft rubber to reach 100% sealing, also installed locks on the head.

High-Speed Disperser With Low-Speed Mixer, which called Dual shaft mixer is widely working in Ink, Adhesive industry, etc. One shaft is a high-speed disperser, another shaft is a low-speed mixer with a scrapper. Which optional system is the vacuum?

Platform Type High-Speed Disperser, Customized size, and function of tanks, also offer mobile tanks. Both MS or SS material tanks.

We also offer related machines such as Bead mill, basket mill, and paint filling machine, etc. We had full project experience in painting, adhesive, graphene, ink, etc.

What you should share with us? the viscosity of the material, capacity, and the process of technology. We will offer the details of machines including drawings, and suggest which machines are suitable for you.

Production Line

-

PCB INK Machine line

FLE supplies all equipments for the production of PCB inks, from the powder feeding station to the filling part.

-

Offset Ink, UV Ink machine line

The FLE engineering company, offer the full set of UV INK Production Line, we can make the full drawing according with your factory size, fo...

-

Offset Ink machine line

FLE is specialized in offset ink full line production for 20+ years. Helped customer save the cost, save the man power, also save the space....

Equipments

News

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

Bead Mill

- SMP Agitator bead mill

- Zirconia beads for sale|Zirconia beads price

- Wet Bead Mill|Bead Mill For Sale

- Sand Mill Machine|Sand Mill For Paint

- Sand Mill|Wet Grinding Equipment Manufacturer

- Bead Mill Machine

- Vertical sand mill

- Bead mill for paint

- Horizontal sand mill

- Turbine bead mill

- Lab bead mill

- Nano Mill

- Vertical Bead Mill

- Bag Filter

- Zirconia Beads

- Pearl Mill

- Dyno mills

- Horizontal Bead Mill

- Agitator bead mill

- Sand Mill

-

Three Roll Mill

-

Twin Shaft Disperser

-

High Speed Disperser

-

Basket Mill

-

High Shear Mixer

-

Double Planetary Mixer

-

Chemical Reactor

-

Kneader

-

Filling Machine

-

Multi-Shaft Mixer

-

Attritor Mill

-

Ribbon Blender

-

Pneumatic Mixer

-

Static Mixer

-

Nitrogen Generator

-

Production Line

- Tricks About Ointment Mill You Wish You ...

- A deep insight into Sand Mill Machine

- What is the difference between dyno mill...

- How To Choose Vertical Bead Mill or Hori...

- What is a three roll mill machine?

- Specification of high speed disperser an...

- Three Roll Mills: Their mechanism, advan...

- high speed disperser machine application

- Faults and Trouble Shooting Methods of H...

- How to operate High-Speed Disperser