-

Equipments

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Or Contact Info

-

Coating

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Adhesives

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Agrochemistry

-

-

Agrochemistry

- Emulsifiable Concentrate

- Suspension Concentrate

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Battery

-

-

Battery

- Battery Slurries

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Cosmetic

-

-

Cosmetic

- Lipstick

- Eyebrow Pencil

- Ointment

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

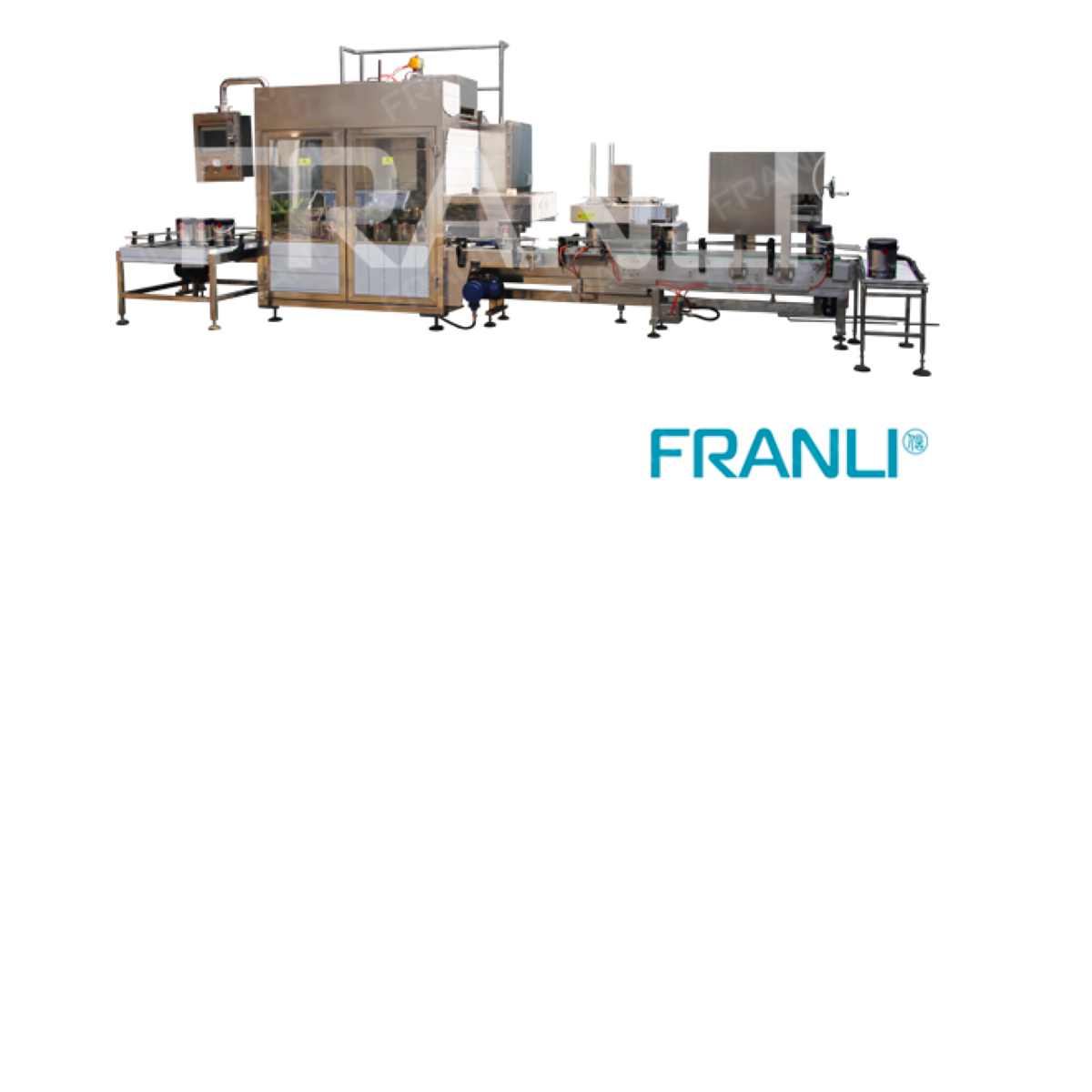

Filling Machine

Filling machines are packaging machines that load precise quantities of packaged products into various containers. From the perspective of material packaging, it can be divided into the liquid filling machine, paste filling machine, powder filling machine, particle filling machine; in terms of the degree of automation of production, it can be divided into semi-automatic filling machine and automatic filling production line.

Filling machines are packaging machines that load precise quantities of packaged products into various containers. From the perspective of material packaging, it can be divided into the liquid filling machine, paste filling machine, powder filling machine, particle filling machine; in terms of the degree of automation of production, it can be divided into semi-automatic filling machine and automatic filling production line.

Application:

gas, liquid, glue, grease, food, agrochemical, medicine, special industry, etc.

Main Parts

An automatic filling machine is a kind of packaging machine. From the perspective of packaging materials, it can be divided into the liquid filling machine, paste filling machine, powder filling machine, particle filling machine; in terms of the degree of automation of production, it can be divided into For semi-automatic filling machines and fully automatic filling production lines. Edible oil manufacturers have begun to pay attention to product quality and packaging, so oil filling machines have a prominent position in filling machines. Filling machines can be divided into atmospheric filling machines, pressure filling machines, liquid filling machines, oil filling machines, paste filling machines, sauce filling machines, and granular slurry filling machines according to the filling principle. , powder filling machine, vat water filling machine and vacuum filling machine.

Granule filling machine

The working principle of the granule filling machine

Granular Slurry Filling Machine is a product that has been transformed and innovatively designed based on advanced filling machine technology. It has a simple structure, high precision, and easier operation. The filling head adopts the anti-drawing and lifting filling device. The filling valve is controlled by a pneumatic valve, and the filling accuracy is higher. The filling volume and filling speed can be adjusted arbitrarily.

Application of Granule Filling Machine

Granule filling machine is suitable for small bag packaging of medicine, food, chemical industry, pesticide and so on. It is suitable for the production of granular drugs, sugar, coffee, fruit, tea, monosodium glutamate, salt, seeds, desiccant, and other fine particle manufacturers.

Liquid Filling Machine

The working principle of the liquid filling machine

According to the different filling pressure, the liquid filling machine is divided into normal pressure liquid filling machine, vacuum liquid filling machine and pressure liquid filling machine.

①Atmospheric pressure liquid filling machine performs self-flow filling according to the weight of the liquid. This type of filling machine has greater requirements on the viscosity and gas content of the liquid. The filling mode is divided into timed filling and constant volume. filling.

②The vacuum filling machine fills the bottle when the pressure in the bottle is lower than the atmospheric pressure. This filling machine has a simple structure and high efficiency and is generally used for liquids with high viscosity.

③Pressure filling machine refers to filling under the condition of higher than normal pressure. It can also be divided into two types: one is that the pressure in the liquid storage tank is equal to the pressure in the bottle, and the filling is carried out by the liquid flowing into the bottle by its weight. It is called isobaric filling; the other is that the pressure in the liquid storage tank is higher than the pressure in the bottle, and the liquid flows into the bottle by the pressure difference. this method.

Application of liquid filling machine

The liquid filling machine is mainly used for liquid filling of lotion, nursing liquid, oral liquid, disinfectant, eyewash, nutrient solution, wine, injection, pesticide, medicine, perfume, edible oil, lubricating oil, and special industries.

Gas filling machine

How the gas filling machine works

The working principle of the gas filling machine is relatively simple. It directly relies on the booster pump to fill the gas to be filled, which is similar to the pressure liquid filling machine.

Commonly used gas filling objects are natural gas, coal gas, nitrogen, carbon dioxide, etc. The gas filling machine has high requirements in the working environment and generally requires filling in a working area with ventilation, low temperature, and no open flame.

Application of gas filling machine

Gas filling machines are widely used in the filling and production of various gas products, such as pure oxygen, fresh air, cassette gas, etc.

The automatic filling machine is also equipped with the entire filling production line, such as a labeling machine, bottle unscrambler, capping machine, capping machine, coding machine, and other production equipment. It can realize automatic bottle sorting, bottle feeding, filling, automatic capping, automatic capping, and then labeling coding, and other production operations. Automatic relies on mechanical transmission and electronic coordination, and semi-automatic is the pneumatic measurement, which requires high precision. According to the operation process, it can be divided into the automatic filling machine and semi-automatic filling machine; according to the nature of the filling product, it can be divided into sauce filling machine, granule filling machine, powder filling machine and liquid filling machine.

Filling machines have always been the strong backing of the packaging industry. In recent years, with the improvement of science and technology, filling machines have developed rapidly. At present, more filling production lines are used. In contrast, filling machines are more efficient. high.

Related Products

More

-

Vacuum Double Planetary Mixer

A Vacuum double planetary mixer is an essential part of any industry to mixing particular material. A double planetary m...

-

Laboratory Double Planetary Mixer

Laboratory double planetary mixer is a kind of non-standardized strong mixing and mixing equipment developed by FLE for ...

-

Hydraulic Lifting High Speed Disperser

The hydraulic lift high speed disperser has the characteristics of simple operation and high flexibility.The hydraulic l...

-

SMP Agitator bead mill

This SMP Agitator bead mill is used in the paint, ink, and coating industries to ready the equal-sized particles of a pa...

-

TRS-Three Roll Mill For Lipstick

TRS Three roll mill is widely used in milling paste material including paint, inks, China ink, pigment, coatings, food, ...

-

Basket Mill Machine

What is a FLE Basket Mill? Our basket mill combines dispersing and grinding into a single machine that is suitable for g...

News

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

Bead Mill

- SMP Agitator bead mill

- Zirconia beads for sale|Zirconia beads price

- Wet Bead Mill|Bead Mill For Sale

- Sand Mill Machine|Sand Mill For Paint

- Sand Mill|Wet Grinding Equipment Manufacturer

- Bead Mill Machine

- Vertical sand mill

- Bead mill for paint

- Horizontal sand mill

- Turbine bead mill

- Lab bead mill

- Nano Mill

- Vertical Bead Mill

- Bag Filter

- Zirconia Beads

- Pearl Mill

- Dyno mills

- Horizontal Bead Mill

- Agitator bead mill

- Sand Mill

-

Three Roll Mill

-

Twin Shaft Disperser

-

High Speed Disperser

-

Basket Mill

-

High Shear Mixer

-

Double Planetary Mixer

-

Chemical Reactor

-

Kneader

-

Filling Machine

-

Multi-Shaft Mixer

-

Attritor Mill

-

Ribbon Blender

-

Pneumatic Mixer

-

Static Mixer

-

Nitrogen Generator

-

Production Line

- Tricks About Ointment Mill You Wish You ...

- A deep insight into Sand Mill Machine

- What is the difference between dyno mill...

- How To Choose Vertical Bead Mill or Hori...

- What is a three roll mill machine?

- Specification of high speed disperser an...

- Three Roll Mills: Their mechanism, advan...

- high speed disperser machine application

- Faults and Trouble Shooting Methods of H...

- How to operate High-Speed Disperser