-

Equipments

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Or Contact Info

-

Coating

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Adhesives

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Agrochemistry

-

-

Agrochemistry

- Emulsifiable Concentrate

- Suspension Concentrate

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Battery

-

-

Battery

- Battery Slurries

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Cosmetic

-

-

Cosmetic

- Lipstick

- Eyebrow Pencil

- Ointment

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Filling Machine

-

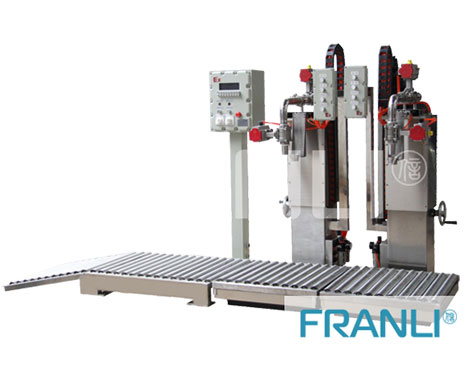

Drum Filling Machine

Drum filling machine is widely used in paint and ink industries. The drum has two kinds of material,...

-

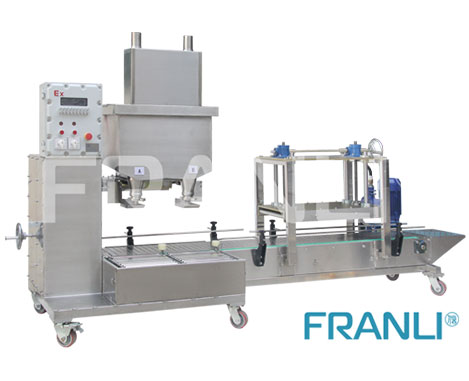

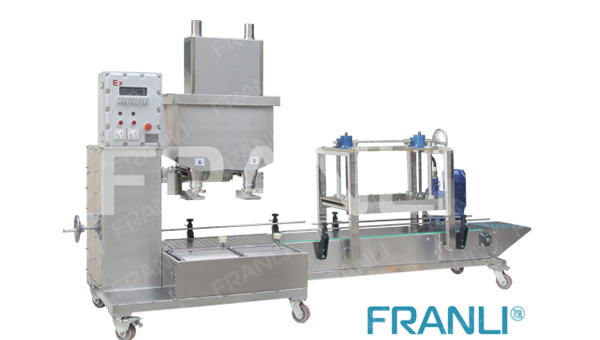

Paint Filling Machine

The paint industry has its own special design paint filling machine, normally choose weight type fil...

-

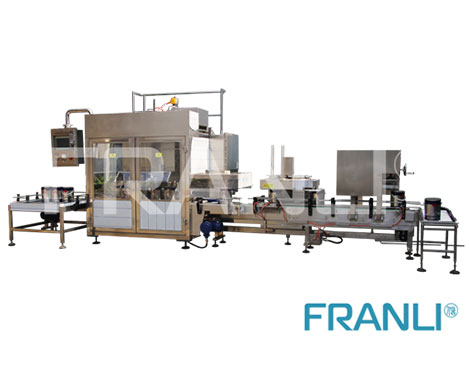

Filling Machine

Filling machines are packaging machines that load precise quantities of packaged products into vario...

FLE filling machines have been used in many industries, including the food industry, daily chemical industry, agrochemical industry, lubricants, etc. In terms of the degree of automation of production, FLE filling machines can be divided into semi-automatic filling machines and fully automatic filling production lines, and there are many types of filling machines involved, including almost the entire filling line.

According to the filing requirements of various products and the required configuration, our filling machines can be divided into atmospheric filling machines, pressure filling machines, liquid filling machines, oil filling machines, and paste filling machines. , Sauce filling machine, granular slurry filling machine, powder filling machine, vat water filling machine, and vacuum filling machine.

Introduction to various filling machines

Atmospheric filling machine

An atmospheric filling machine is a kind of liquid filling machine. It mainly uses the weight of the liquid under atmospheric pressure to input the liquid. This type of filling machine is mainly suitable for liquid tanks with low viscosity and no gas. Equipment, such as milk, white wine, purified water, mineral water, etc. For the atmospheric filling machine, we will upgrade it according to its own advantages and characteristics, and divide it into two ways: fixed-time canning and constant-volume canning.

Pressure filling machine

The principle of pressure filling machines is similar to that of atmospheric pressure filling machines. They both use atmospheric pressure for filling, but the two are just the opposite. They are mainly used for filling input when the pressure is higher than the atmospheric pressure. The application type of the pressure filling machine is also for liquid canning, but on the contrary, it is mainly suitable for canning liquids containing gas, such as beverage soda, beer, soda, etc. The entire canning environment needs to be higher than the atmosphere Under stress. Due to the difference in pressure, we divide the pressure filling machine into two types of production: one is that when the pressure in the liquid storage cylinder reaches the same value as the pressure in the bottle, it needs to pass the weight of the liquid itself to flow into the bottle. The filling is called isobaric filling; the other is when the pressure in the liquid storage tank is higher than the pressure in the bottle, the liquid needs to rely on the air pressure difference to flow into the bottle. Many companies want to achieve high-speed production lines, This method is generally used.

Vacuum filling machine

The vacuum filling machine is one of the most popular machines in the FLE canning series, mainly because of its simple structure and its high advantages in canning efficiency. When it comes to vacuum canning, it is not difficult to understand that it also has a certain relationship with air pressure. When the pressure in the bottle is lower than atmospheric pressure, a vacuum filling machine can be used for compression. It has no specific restrictions on the viscosity of the material. That is to say, its overall use range is extremely wide.

Grease filling machine

Oil canning requires certain technical conditions, including filling various oil products, such as edible oil, lubricating oil, peanut oil, soybean oil, etc. According to this type of filling machine, it is a filling machine specially developed and developed for the filling of oil materials, which can realize the flexible configuration of manual operation and unmanned operation. Generally, we divide the type of grease filling machine according to the measurement method, which can be divided into flowmeter type, piston type, weighing type, and other types. Not only that, but we also divide the filling machine into the linear type and rotary type according to the equipment style.

Plug filling machine

With the improvement of living materials, the demand for food, agrochemical, daily chemical, pharmaceutical, oil, and other industries is also increasing, but for the canning of such products, there must be a new type of machine that adapts to multiple industries. The design of the plug-in filling machine solves this kind of demand, not only has a wide range of applications but also can greatly improve work efficiency and filling speed.

Liquid filling machine

The liquid filling machine has been upgraded and updated many times. At present, the newly designed liquid filling machine of FLE adopts a horizontal design, which has the advantages of lightness and convenience. It can realize automatic feeding, and can also self-adjust for feeding for thicker pastes. The system is equipped with manual and automatic mutual switching functions: when the machine is in the "automatic" state, the system will automatically start continuous filling of the product at the set speed. When the system is in the "manual" state, the operator needs to step on the pedal of the filling machine to achieve filling. If you keep stepping on it, it will also change the original state and become automatic continuous filling. status. The liquid filling machine is equipped with a drip-proof filling system. Its working principle is mainly that when the filling machine is filling, the cylinder moves up and down to drive the bulkhead.

1. The liquid filling machine can be matched and selected accessories

a. Needle type filling head: it can be suitable for filling small-caliber bottles and tube packaging products. The diameter and length of the needle part can be determined or customized according to the specific conditions of the container.

b. Turn/ball valve control system: suitable for materials with different viscosities and particles, and can solve various pressure problems caused by high-position and high-pressure feeding.

c. Hopper: We generally recommend that the factory use it when filling products with a higher viscosity so that the machine can achieve better filling results.

Paste filling machine

The paste filling machine is the best equipment for canning low-viscosity liquids to high-viscosity pastes. Many such daily chemical, pharmaceutical, and food industries are full of praise for it. It is compatible with liquid filling machines. The design is similar. It also adopts a horizontal design and has many advantages of a liquid filling machine. For thicker pastes, you can also add hoppers to feed. The operating conditions involved are basically similar to those of the liquid filling machine.

Sauce filling machine

The sauce filling machine is undoubtedly a boon for products such as chili sauce, bean paste, peanut butter, sesame paste, jam, butter hot pot base, red oil hot pot base, and other products with particles and high concentration in condiments, not only It can improve the quality of canned thick sauces, and can also complete canning with maximum efficiency. For sauce filling machines, FLE mainly produces two types of automatic filling machines and semi-automatic filling machines according to the user's usage habits.

Weighing filling machine

For liquid materials with relatively low viscosity, the weighing filling machine has the characteristics of high-precision canning, few wearing parts, and simple maintenance. And it has high applicability in chemical raw materials such as paints, coatings, and resins.

Granular slurry filling machine

In the pharmaceutical, daily chemical, food, pesticide, and special industries, there are many granular and slurry-like viscosity fluids. When these materials are canned, the machine must have certain granular canning conditions. The granular slurry filling machine manufactured by FLE It can make up for this. The type of this machine is a semi-automatic piston filling machine, which can fill granular slurry fluid materials with high efficiency.

Production Line

-

PCB INK Machine line

FLE supplies all equipments for the production of PCB inks, from the powder feeding station to the filling part.

-

Offset Ink, UV Ink machine line

The FLE engineering company, offer the full set of UV INK Production Line, we can make the full drawing according with your factory size, fo...

-

Offset Ink machine line

FLE is specialized in offset ink full line production for 20+ years. Helped customer save the cost, save the man power, also save the space....

Equipments

News

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

Bead Mill

- SMP Agitator bead mill

- Zirconia beads for sale|Zirconia beads price

- Wet Bead Mill|Bead Mill For Sale

- Sand Mill Machine|Sand Mill For Paint

- Sand Mill|Wet Grinding Equipment Manufacturer

- Bead Mill Machine

- Vertical sand mill

- Bead mill for paint

- Horizontal sand mill

- Turbine bead mill

- Lab bead mill

- Nano Mill

- Vertical Bead Mill

- Bag Filter

- Zirconia Beads

- Pearl Mill

- Dyno mills

- Horizontal Bead Mill

- Agitator bead mill

- Sand Mill

-

Three Roll Mill

-

Twin Shaft Disperser

-

High Speed Disperser

-

Basket Mill

-

High Shear Mixer

-

Double Planetary Mixer

-

Chemical Reactor

-

Kneader

-

Filling Machine

-

Multi-Shaft Mixer

-

Attritor Mill

-

Ribbon Blender

-

Pneumatic Mixer

-

Static Mixer

-

Nitrogen Generator

-

Production Line

- Tricks About Ointment Mill You Wish You ...

- A deep insight into Sand Mill Machine

- What is the difference between dyno mill...

- How To Choose Vertical Bead Mill or Hori...

- What is a three roll mill machine?

- Specification of high speed disperser an...

- Three Roll Mills: Their mechanism, advan...

- high speed disperser machine application

- Faults and Trouble Shooting Methods of H...

- How to operate High-Speed Disperser