-

Equipments

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Or Contact Info

-

Coating

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Adhesives

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Agrochemistry

-

-

Agrochemistry

- Emulsifiable Concentrate

- Suspension Concentrate

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Battery

-

-

Battery

- Battery Slurries

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Cosmetic

-

-

Cosmetic

- Lipstick

- Eyebrow Pencil

- Ointment

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

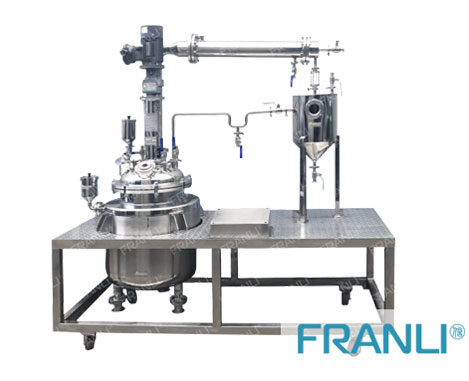

Chemical Reactor

-

Reactor Mixer

The reactor mixer can be divided into three categories: steel reactor mixer, cast iron reactor mixer...

-

Glass Reactor

Glass reactors are divided into single-layer glass reactors, double-layer glass reactors, with vacuu...

-

Stainless Steel Reactor

The reaction vessel is a comprehensive reaction vessel. The structure, function, and configuration a...

-

Industrial Chemical Reactor

The working principle of the industrial chemical reactor is that the reaction solvent can be put int...

-

Chemical Reactor

The usual understanding of the chemical reactor is a container with physical or chemical reactions. ...

The usual understanding of the chemical reactor is a container with physical or chemical reactions. Through the structural design and parameter configuration of the container, the heating, evaporation, cooling, and low-speed mixing functions required by the process can be realized.

The usual understanding of the chemical reactor is a container with physical or chemical reactions. Through the structural design and parameter configuration of the container, the heating, evaporation, cooling, and low-speed mixing functions required by the process can be realized.

Chemical reactors are widely used in petroleum, chemical, rubber, pesticides, dyes, medicines, foods industries, and pressure vessels used to complete vulcanization, nitrification, hydrogenation, alkylation, polymerization, condensation, and other processes, such as reactors, reaction pots, and decomposition pots., Polymerization kettle, etc.; materials generally include carbon-manganese steel, stainless steel, zirconium, nickel-based (Hastelloy, Monel, Inconel) alloys, and other composite materials.

The chemical reaction kettle is a comprehensive reaction vessel. The structure, function, and configuration accessories of the chemical reaction kettle are designed according to the reaction conditions. From the beginning of the feed-reaction-discharge, the pre-set reaction steps can be completed with a high degree of automation, and the temperature, pressure, mechanical control (stirring, blast, etc.), reactants/products during the reaction process Important parameters such as concentration are strictly regulated. Its structure is generally composed of a kettle body, a transmission device, a stirring device, a heating device, a cooling device, and a sealing device.

Corresponding auxiliary equipment for the chemical reactor: fractionating column, condenser, water separator, collection tank, filter, etc.

Chemical reactor assembly line or a full set of automated factories for mass production

We have extensive experience in computer-controlled automated factories.

We can provide turnkey factories, including reactors and mixers, pipes and valves, storage tanks, woodworking support, power supply, and computer control systems.

The above reactor facilities can be used for the following chemicals for different purposes:

l Cosmetics

l Detergent

l Auxiliary chemicals used for surface treatment in the textile or leather industry

l Mixing of lubricants

A complete set of chemical reactor equipment for adhesive production (used for tape production or footwear production, or market sales)

The chemical reactor equipped with a special stirrer can effectively and quickly dissolve the components to be mixed. Complete PU (polyurethane) paste preparation/PVC paste in synthetic leather production.

Some information about our automated factories in this field:

l A single batch of up to 4000 kg (or higher specifications can be customized)

l A fully automatic factory controlled by a computer system can ensure the precise synthesis ratio of the reactor

l Vacuum processing

l Automatic loading of all ingredients including powder

l Suitable for discharging the paste into the tank and supplying the spraying line

Resin production plant

Turnkey factory supporting technology (process formula + training):

l Brominated resin

l Unsaturated polyester PE

l Saturated polyester PE

l Epoxy resin

l Acrylic

l Phenolic

l Alkyd

About formaldehyde:

l Formaldehyde production plant

l Wood glue factory

l Paper impregnated resin factory

l New technologies and factories allow the use of formaldehyde to provide the efficiency of urea fertilizer

Production Line

-

PCB INK Machine line

FLE supplies all equipments for the production of PCB inks, from the powder feeding station to the filling part.

-

Offset Ink, UV Ink machine line

The FLE engineering company, offer the full set of UV INK Production Line, we can make the full drawing according with your factory size, fo...

-

Offset Ink machine line

FLE is specialized in offset ink full line production for 20+ years. Helped customer save the cost, save the man power, also save the space....

Equipments

News

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

Bead Mill

- SMP Agitator bead mill

- Zirconia beads for sale|Zirconia beads price

- Wet Bead Mill|Bead Mill For Sale

- Sand Mill Machine|Sand Mill For Paint

- Sand Mill|Wet Grinding Equipment Manufacturer

- Bead Mill Machine

- Vertical sand mill

- Bead mill for paint

- Horizontal sand mill

- Turbine bead mill

- Lab bead mill

- Nano Mill

- Vertical Bead Mill

- Bag Filter

- Zirconia Beads

- Pearl Mill

- Dyno mills

- Horizontal Bead Mill

- Agitator bead mill

- Sand Mill

-

Three Roll Mill

-

Twin Shaft Disperser

-

High Speed Disperser

-

Basket Mill

-

High Shear Mixer

-

Double Planetary Mixer

-

Chemical Reactor

-

Kneader

-

Filling Machine

-

Multi-Shaft Mixer

-

Attritor Mill

-

Ribbon Blender

-

Pneumatic Mixer

-

Static Mixer

-

Nitrogen Generator

-

Production Line

- Tricks About Ointment Mill You Wish You ...

- A deep insight into Sand Mill Machine

- What is the difference between dyno mill...

- How To Choose Vertical Bead Mill or Hori...

- What is a three roll mill machine?

- Specification of high speed disperser an...

- Three Roll Mills: Their mechanism, advan...

- high speed disperser machine application

- Faults and Trouble Shooting Methods of H...

- How to operate High-Speed Disperser