-

Equipments

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Or Contact Info

-

Coating

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Adhesives

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Agrochemistry

-

-

Agrochemistry

- Emulsifiable Concentrate

- Suspension Concentrate

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Battery

-

-

Battery

- Battery Slurries

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Cosmetic

-

-

Cosmetic

- Lipstick

- Eyebrow Pencil

- Ointment

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Bead Mill Machine

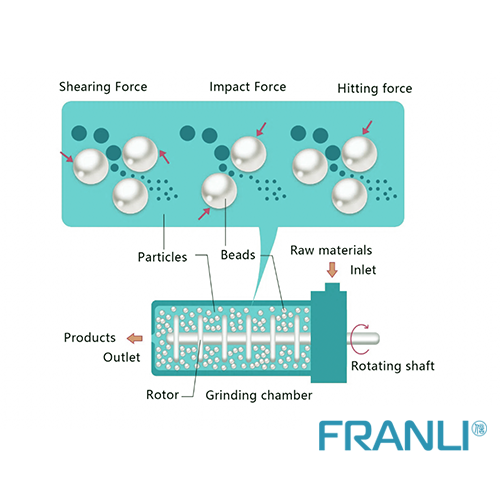

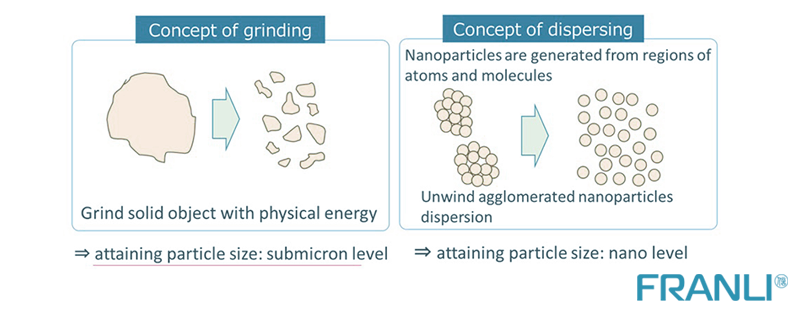

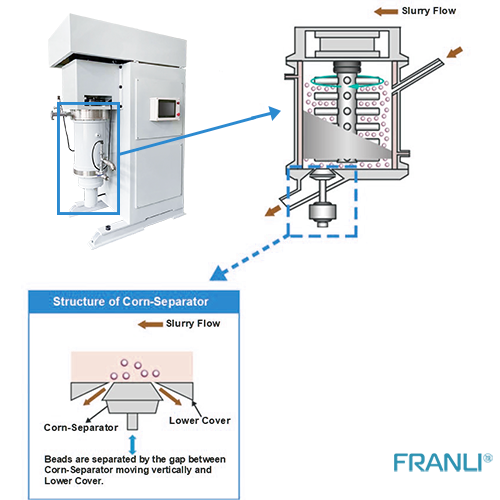

Bead mill machine is a microscopic and nanotechnology grind and dispersion device. The particulates are ground and/or distributed by the collisions and friction stress of the beading within the bottom chamber, which is agitation by spinning the shafts. The grinding committee's output features a filtering mechanism that separates beads from grains, allowing for the continued manufacture of small particles while keeping beading within the container. Bead mill machines are among the numerous technologies used throughout the laboratories for milling, neutralising, and homogenising materials. Bead mill machines are commonly sometimes used homogenise materials that are challenging to destabilize using traditional mechanical laboratories. Tumours, hearts, e-coli, yeast, bone, skin, cartilage, spores, seeds, and soil are among the types of samples. Bead mill machines also could recover nucleotide acids that play an important role from complicated microorganisms, including microalgae, mycobacterium, and phytoplankton.

Bead mill machine is a microscopic and nanotechnology grind and dispersion device. The particulates are ground and/or distributed by the collisions and friction stress of the beading within the bottom chamber, which is agitation by spinning the shafts. The grinding committee's output features a filtering mechanism that separates beads from grains, allowing for the continued manufacture of small particles while keeping beading within the container. Bead mill machines are among the numerous technologies used throughout the laboratories for milling, neutralising, and homogenising materials. Bead mill machines are commonly sometimes used homogenise materials that are challenging to destabilize using traditional mechanical laboratories. Tumours, hearts, e-coli, yeast, bone, skin, cartilage, spores, seeds, and soil are among the types of samples. Bead mill machines also could recover nucleotide acids that play an important role from complicated microorganisms, including microalgae, mycobacterium, and phytoplankton.

Physical properties:

Microscopic glass, ceramics, or stainless beads are used in Bead mill machines. Those beads, together as the sampling medium, are put in a beaker. Shake or swirling is used to aggressively circulate the jar, beads, and material. As the beads hit both the cells quickly, the samples are disrupted. The use of polishing beads and the rotating action results in a quicker and much more consistent lysis buffer procedure for biological materials. A greater volume proportion of beads to colonies usually results in quicker cell lysis. The beads descend by gravitational force in the jar once the grinding cycle is completed, and the resultant mash is readily extracted using a dropper. Since they use throwaway beads and collection tubes, Bead mill machines are largely merged, independent. Sampling techniques of overexpressing or smaller are limited among most stirring Bead mill machines. Multiple specimens, on the other hand, can be handled at the same moment. Heating may be an issue utilizing Bead mill machine, however many of today's modern models come with refrigeration towers and equipment as options.

How do you pick the right sort of bead mill machine?

To generate modern materials nanocomposite, AlN nanostructures have been spread in cooling water using a bead mill machine. Such a device diffuses materials via directly impacting aggregates of nanotechnology with threads of a certain diameter that are cycled inside the grinding container via additional Lorentz force. The ideal operating characteristics of a bead mill machine operation were determined using a mathematical formula to look at population balances. This processes model's dynamic model yielded two equations subgroups, indicates the relative power of such mill's coagulate or breaking phenomenon.

Bead mill machine - An Insight

Generally, supersonic bead mill machines are best suited to limited water sampling operations. These seem to be more appropriate in greater quantities and may be expanded up to the point, although the technique does not grow along with others yet they are seldom used in manufacturing. Cleaning your sensor around every operation may even be a moment if you do need to analyse several materials throughout quick order. That's also particularly true when you're worried about the infection and will need to wash everything thoroughly every time. There are various cup trumpets on the market that allow supersonic power to be delivered to a measured relative even without an instrument interacting directly with them. All those are beneficial for reducing bridge, but they're only appropriate for low-volume projects that don't need greater treatment mills.

Manufactures of bead mill machines

We provide a wide selection of bead mill machine, all of which are made from high-quality raw materials to assure the best outcome in the finished result. Its splashing show includes some good agitation disks that aids in efficient electron transport from the major engines to the grinder beads. This also allows solid material to be broken down into a more grounding state. As a result, our bead mill machine could be praised for their high energy efficiency, excellent result, and smooth grinding result.

l A bead mill machine is a flexible wet milling system that has been particularly built.

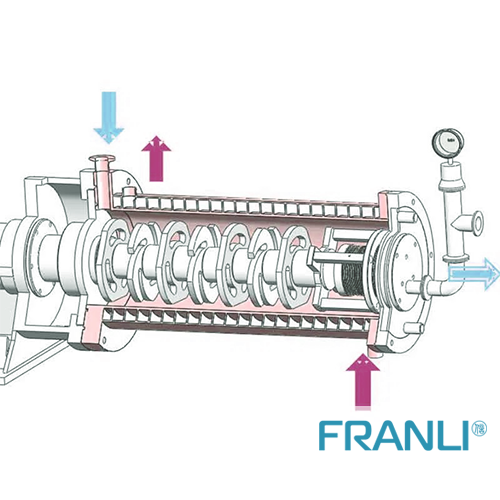

l Increased water rates are ensured by a specialized centrifuge separation process, which also achieves a significant level of crushing.

l Technology with cooling and heating systems for precise heating and cooling.

l Micro grinding of even the toughest materials is very productive as a result.

l Suitable for both aqueous and preservative sludges.

As a result, paint manufacturers may utilise this fantastic and adaptable mixing machinery to assist their clients in applying a sufficient liquid foundation to the required steel surface. You may rest easy knowing that the machine is made using grading metals, mild steel, metal alloys, and silver by industry requirements. Chose this particular machine to establish a strong foundation for high-quality painting.

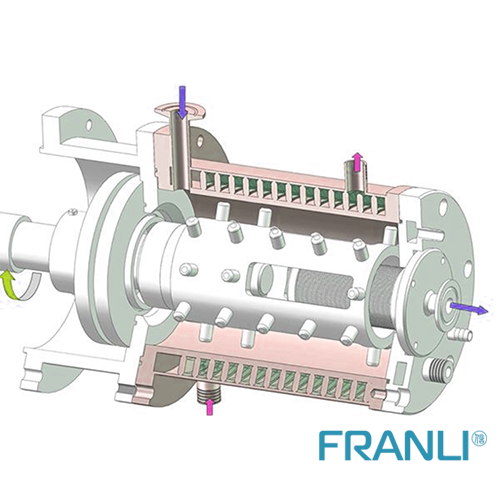

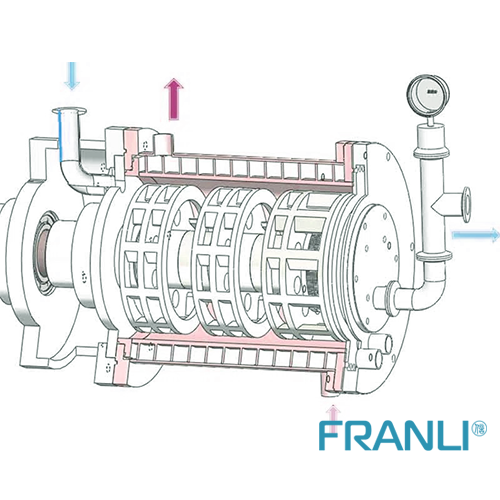

Bead mill machine working Principle

The shafts with agitation disks are housed in the horizontal hammer mill of such a bead mill machine. The column is packed with a zirconia grinding medium, with a double functioning piping system that prevents material leaking. A diaphragmatic pumping or a screws pump moves the materials through into the container. The agitation disks transfer the energy needed for dispersing and milling to the crushing beads. The mill is constantly supplied by the pumps. The length of time the substance spends within the container is determined by the flow rate.

A cartridge is used to keep the milled beads within the chambers. Its mill's performance is enhanced by making the most of the power supplied into the chambers for dispersal and milling.

Applications:

Wet milling of fluids and pigments inserts is done with bead mill machines. They've been around for a long time and are frequently used in the paints and chemicals industry. The bead mill machine is a member of the impeller and ideologue families. The ideologue has entirely transformed the conventional grinding machine in the liquid milling of coatings and adhesives because this presses & diffuses constantly and so more effectively.

l Inks for printing

l Chemicals found in leather

l Inks for flexo printing

l Inkjet printers

l Paints

l Preparations for pigment

l Filler

l Chemicals used in agriculture

l Coatings magnetic

l Pharmaceuticals

l Coatings for Thermal Paper

l Chocolate

FLE has a collection of large bead mill machine models that can manage nearly any sort of dispersal. FLE's dispersion equipment is well-suited to a variety of sectors, including aerospace, microelectronics, agrochemicals, cosmetics, digital printing, and medical device applications.

With bead mill machines, FLE has the research & design expertise and also the manufacturing capability to generate fine solid dispersion. To manage any dispersal assignment, FLE offers an R&D bead-milling simulation, nanoparticle mills, manufacturing mills, and government characterisation facilities.

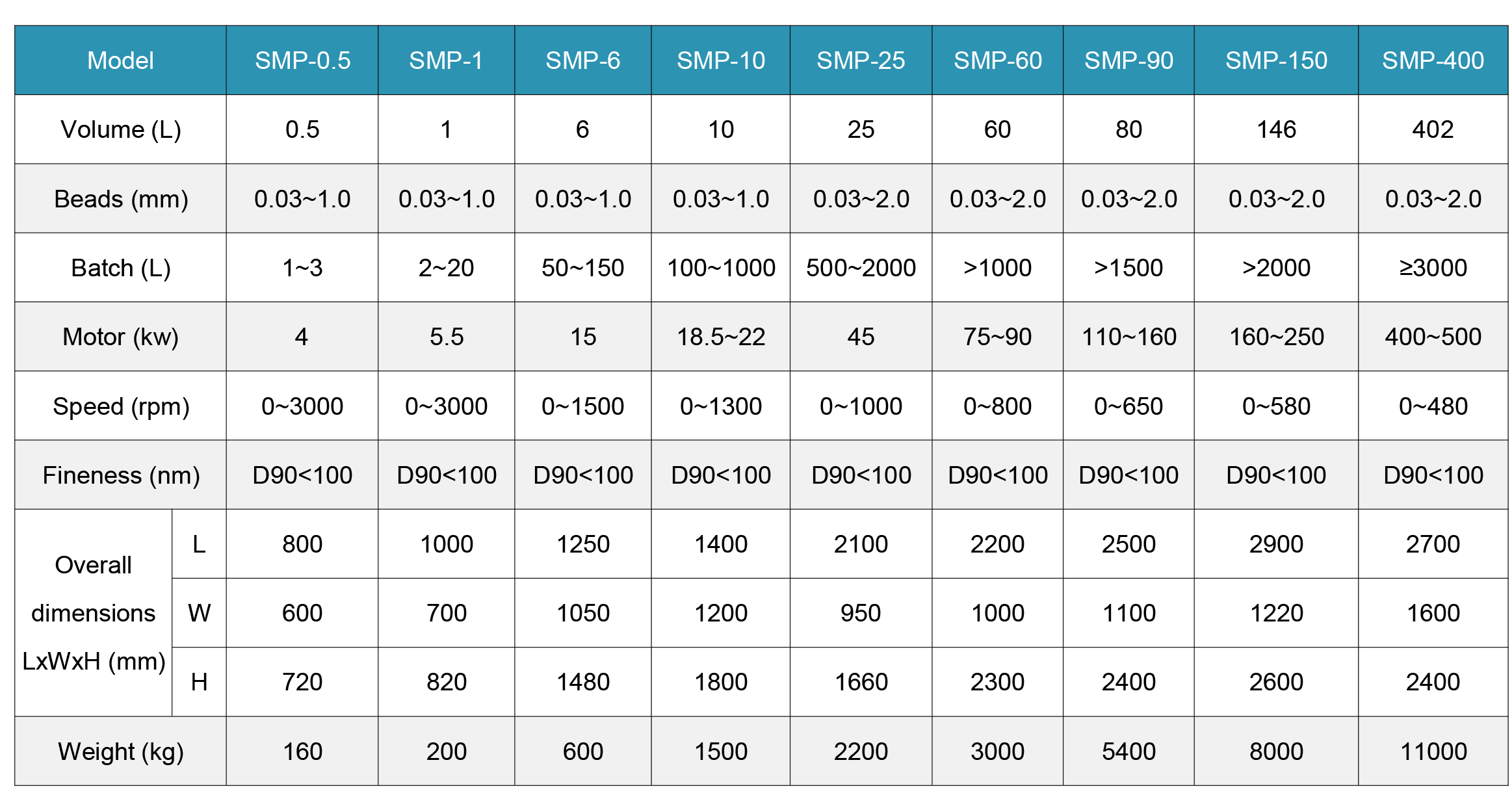

Main Technical Parameters

Application

Related Products

More

-

Vacuum Double Planetary Mixer

A Vacuum double planetary mixer is an essential part of any industry to mixing particular material. A double planetary m...

-

Laboratory Double Planetary Mixer

Laboratory double planetary mixer is a kind of non-standardized strong mixing and mixing equipment developed by FLE for ...

-

Hydraulic Lifting High Speed Disperser

The hydraulic lift high speed disperser has the characteristics of simple operation and high flexibility.The hydraulic l...

-

SMP Agitator bead mill

This SMP Agitator bead mill is used in the paint, ink, and coating industries to ready the equal-sized particles of a pa...

-

TRS-Three Roll Mill For Lipstick

TRS Three roll mill is widely used in milling paste material including paint, inks, China ink, pigment, coatings, food, ...

-

Basket Mill Machine

What is a FLE Basket Mill? Our basket mill combines dispersing and grinding into a single machine that is suitable for g...

News

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

Bead Mill

- SMP Agitator bead mill

- Zirconia beads for sale|Zirconia beads price

- Wet Bead Mill|Bead Mill For Sale

- Sand Mill Machine|Sand Mill For Paint

- Sand Mill|Wet Grinding Equipment Manufacturer

- Bead Mill Machine

- Vertical sand mill

- Bead mill for paint

- Horizontal sand mill

- Turbine bead mill

- Lab bead mill

- Nano Mill

- Vertical Bead Mill

- Bag Filter

- Zirconia Beads

- Pearl Mill

- Dyno mills

- Horizontal Bead Mill

- Agitator bead mill

- Sand Mill

-

Three Roll Mill

-

Twin Shaft Disperser

-

High Speed Disperser

-

Basket Mill

-

High Shear Mixer

-

Double Planetary Mixer

-

Chemical Reactor

-

Kneader

-

Filling Machine

-

Multi-Shaft Mixer

-

Attritor Mill

-

Ribbon Blender

-

Pneumatic Mixer

-

Static Mixer

-

Nitrogen Generator

-

Production Line

- Tricks About Ointment Mill You Wish You ...

- A deep insight into Sand Mill Machine

- What is the difference between dyno mill...

- How To Choose Vertical Bead Mill or Hori...

- What is a three roll mill machine?

- Three Roll Mills: Their mechanism, advan...

- Specification of high speed disperser an...

- high speed disperser machine application

- Faults and Trouble Shooting Methods of H...

- How to operate High-Speed Disperser