-

Equipments

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Or Contact Info

-

Coating

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Adhesives

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Agrochemistry

-

-

Agrochemistry

- Emulsifiable Concentrate

- Suspension Concentrate

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Battery

-

-

Battery

- Battery Slurries

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Cosmetic

-

-

Cosmetic

- Lipstick

- Eyebrow Pencil

- Ointment

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

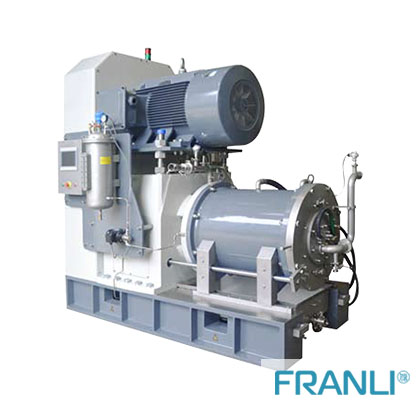

Horizontal sand mill

The horizontal sand mill adopts a cyclic grinding process, and according to European advanced design standards, FRANLI's horizontal sand mill has the characteristics of better control ability, high energy conversion rate, and large flow rate, which can achieve nano-level grinding requirements. The range of particle size distribution is narrow. Widely used in gravure inks, automotive coatings, coil coatings, ceramics, inks, inkjets, color filter separators, functional ceramics, lithium battery materials, thermal paper, anti-corrosion coatings, wood coatings, etc., covering a wide range of fields, Can almost meet all needs of nano-scale wet grinding.

The horizontal sand mill adopts a cyclic grinding process, and according to European advanced design standards, FRANLI's horizontal sand mill has the characteristics of better control ability, high energy conversion rate, and large flow rate, which can achieve nano-level grinding requirements. The range of particle size distribution is narrow. Widely used in gravure inks, automotive coatings, coil coatings, ceramics, inks, inkjets, color filter separators, functional ceramics, lithium battery materials, thermal paper, anti-corrosion coatings, wood coatings, etc., covering a wide range of fields, Can almost meet all needs of nano-scale wet grinding.

FRANLI Machinery keeps improving according to the needs of different industries. This horizontal sand mill can not only improve efficiency and reduce labor but also has made outstanding achievements in environmental protection. The adjustable dynamic separator used is made of high wear-resistant powder alloy, which has the characteristics of self-cleaning and adjustable gaps. Users can choose 0.1mm grinding media, which creates effective conditions for the grinding effect of the product.

The working process of the FRANLI horizontal sand mill

Under normal circumstances, we need to configure the original slurry first, after a simple grinding, pump it into the circulating mixing tank, and transport it through the bottom pump into the horizontal sand mill. The material enters the circulation while being ground by the sand mill. The tank and the unground materials are quickly stirred and mixed under the action of the mixer, and then pumped into the sand mill through the bottom again. After multiple cycles, the final effect that the user wants to achieve is achieved. The volume of the tank can reach 1/4 of the flow rate of the sand mill.

Advantages and characteristics of horizontal sand mill

l The horizontal sand mill adopts a brand-new static centrifugal separation device, which has a large flow rate to ensure smooth and stable discharge.

l Completely realize the nano-level grinding effect, and can use the grinding medium of 0.1mm or more.

l According to different products, different materials can be selected, such as silicon carbide, zirconia, polyurethane, cemented carbide, etc.

l The arrangement of the cylinder and the rotor refers to the golden ratio as the standard, which effectively reduces the degree of wear on itself, and on the other hand, it expands the energy utilization rate and achieves the best grinding state.

l The whole machine has been optimized and upgraded many times, and the overall stability of the equipment has been improved.

l Multiple cooling modes can effectively reduce the heat problem caused by grinding.

FRANLI's new horizontal sand mill has a complete grinding function, and far surpasses the traditional sand mill, raising the wet grinding effect to another level. Our engineers provide 24-hour functional consultation and effect testing and provide formulas for the grinding effect of various materials.

Application

Related Products

More

-

Vacuum Double Planetary Mixer

A Vacuum double planetary mixer is an essential part of any industry to mixing particular material. A double planetary m...

-

Laboratory Double Planetary Mixer

Laboratory double planetary mixer is a kind of non-standardized strong mixing and mixing equipment developed by FLE for ...

-

Hydraulic Lifting High Speed Disperser

The hydraulic lift high speed disperser has the characteristics of simple operation and high flexibility.The hydraulic l...

-

SMP Agitator bead mill

This SMP Agitator bead mill is used in the paint, ink, and coating industries to ready the equal-sized particles of a pa...

-

TRS-Three Roll Mill For Lipstick

TRS Three roll mill is widely used in milling paste material including paint, inks, China ink, pigment, coatings, food, ...

-

Basket Mill Machine

What is a FLE Basket Mill? Our basket mill combines dispersing and grinding into a single machine that is suitable for g...

News

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

Bead Mill

- SMP Agitator bead mill

- Zirconia beads for sale|Zirconia beads price

- Wet Bead Mill|Bead Mill For Sale

- Sand Mill Machine|Sand Mill For Paint

- Sand Mill|Wet Grinding Equipment Manufacturer

- Bead Mill Machine

- Vertical sand mill

- Bead mill for paint

- Horizontal sand mill

- Turbine bead mill

- Lab bead mill

- Nano Mill

- Vertical Bead Mill

- Bag Filter

- Zirconia Beads

- Pearl Mill

- Dyno mills

- Horizontal Bead Mill

- Agitator bead mill

- Sand Mill

-

Three Roll Mill

-

Twin Shaft Disperser

-

High Speed Disperser

-

Basket Mill

-

High Shear Mixer

-

Double Planetary Mixer

-

Chemical Reactor

-

Kneader

-

Filling Machine

-

Multi-Shaft Mixer

-

Attritor Mill

-

Ribbon Blender

-

Pneumatic Mixer

-

Static Mixer

-

Nitrogen Generator

-

Production Line

- Tricks About Ointment Mill You Wish You ...

- A deep insight into Sand Mill Machine

- What is the difference between dyno mill...

- How To Choose Vertical Bead Mill or Hori...

- What is a three roll mill machine?

- Specification of high speed disperser an...

- Three Roll Mills: Their mechanism, advan...

- high speed disperser machine application

- Faults and Trouble Shooting Methods of H...

- How to operate High-Speed Disperser