-

Equipments

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Or Contact Info

-

Coating

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Adhesives

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Agrochemistry

-

-

Agrochemistry

- Emulsifiable Concentrate

- Suspension Concentrate

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Battery

-

-

Battery

- Battery Slurries

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Cosmetic

-

-

Cosmetic

- Lipstick

- Eyebrow Pencil

- Ointment

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Agitator bead mill

Pin type bead mill (PDF documents related to Agitator FLE BEAD MILL:

Pin type bead mill (PDF documents related to Agitator FLE BEAD MILL:![]() )is our Agitator bead mill machine, which is popular in Battery Industry, Digital Consumptive, Ceramic Materials, Mineral Pigment, Rare-earth material, Cosmetics, Pharmaceutical, etc.

)is our Agitator bead mill machine, which is popular in Battery Industry, Digital Consumptive, Ceramic Materials, Mineral Pigment, Rare-earth material, Cosmetics, Pharmaceutical, etc.

Agitator bead mill’s pins are uniform distributed type, pre-milling your material when feeding material into chamber. The agitator bead mill has a stronger power motor, material milled by bead, and pins in the chamber. Big decisive material will cycling mill in the chamber, milled material becomes lower density, which outlet from the customized size of screen mesh.

If you choose this Agitator bead mill machine, totally improved your production capacity, and reaches nanomaterial, which tested by Malvern, Universal size can be less than 50nm.

advantages of agitator bead mill

1.Higher production flowing

2.Brand parts of nano mill

3.<50nm tested by Malvern

4.Stable, easily working process

5.Details of Agitator bead mill

Rotor with Pin

Optional material: PU, Zirconia, Hardness Alloy

Different Pin type for different material

Motor Brand

Optional: ABB, SIEMENS, Chinese Brand

Ex-proof Parts

International Standard Ex-proof Grade

Pump

INGERSOLL Rand Brand for low viscosity,

USA Gear pump for High viscosity Material.

Agitator bead mill

Agitator bead mill is a pin rotor bead mill, the shape is the vertical type and horizontal type. The Agitator bead mill working principle can be single batch milling, cycling milling with another pre-sand mill machine also can be cycling mill with two tanks for 30mins or 1h. which working way is according with customer’s material.

Agitator bead mill most produces TFT or PLC screen material. If you choose this type of Agitator bead mill, your surface painting becomes more lighting, heavy coating with higher resistance, Nona level painting becomes more brilliant, enhance color strength. If you choose Agitator bead mill for package ink or sliver ink, which becomes more gloss and transparency.

Horizontal Agitator bead mill is higher production than disc horizontal bead mill, Agitator bead mill has stronger motor power for grinding. Agitator bead mill has a full cooling system at the chamber, mechanical sealing, outlet place, etc. Speed is 0-1000rpm controlled by ABB VFD. Nano mill’s separator makes beads uniform distribution in the chamber, which makes your material grinding more smoothy and uniform.

How many beads should feed into one Agitator bead mill? Chamber capacity X (70% to 80%) is beads quantity. We signed with one biggest zirconia beads suppliers in China, which can offer our customers the best price and stable quality. Welcome to connect with us!

We also have related machines

Twin Shaft Mixer

One is a high-speed disperser, another one is a low-speed mixer with a scraper to scrape materials on the tank. Can be a customized Vacuum system.

Paint Filling Machine

Weight type filling machine for the painting industry, opening type hopper is easily washing to change the different color of the painting. Design according to with your shape and size of cans.

Inline Emulsifier

More effective inline emulsifier, high lift >10m with high viscosity pump, can deal with 120,000cps material, inner size max around 2cm.

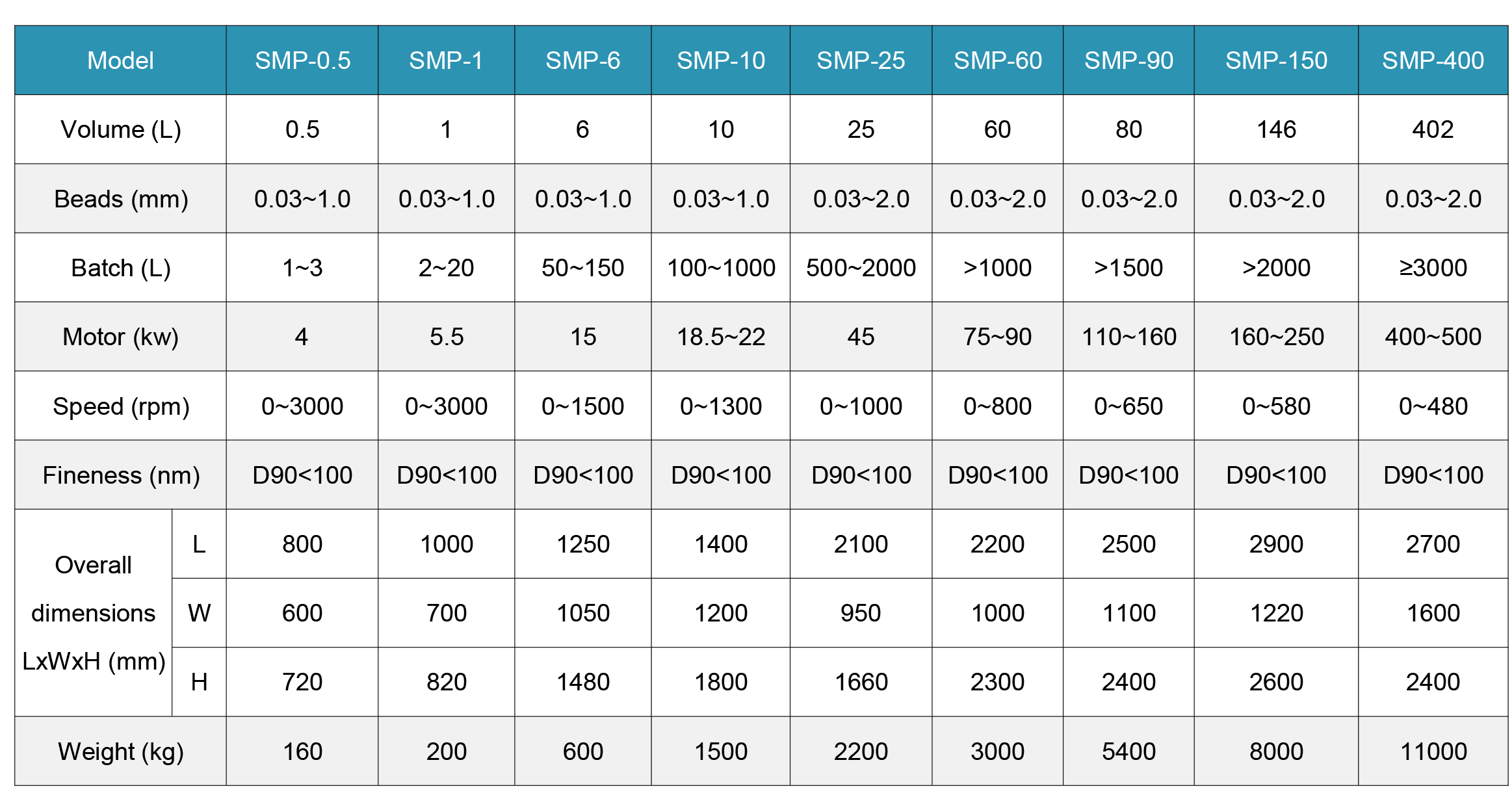

Main Technical Parameters

Application

Related Products

More

-

Vacuum Double Planetary Mixer

A Vacuum double planetary mixer is an essential part of any industry to mixing particular material. A double planetary m...

-

Laboratory Double Planetary Mixer

Laboratory double planetary mixer is a kind of non-standardized strong mixing and mixing equipment developed by FLE for ...

-

Hydraulic Lifting High Speed Disperser

The hydraulic lift high speed disperser has the characteristics of simple operation and high flexibility.The hydraulic l...

-

SMP Agitator bead mill

This SMP Agitator bead mill is used in the paint, ink, and coating industries to ready the equal-sized particles of a pa...

-

TRS-Three Roll Mill For Lipstick

TRS Three roll mill is widely used in milling paste material including paint, inks, China ink, pigment, coatings, food, ...

-

Basket Mill Machine

What is a FLE Basket Mill? Our basket mill combines dispersing and grinding into a single machine that is suitable for g...

News

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

Bead Mill

- SMP Agitator bead mill

- Zirconia beads for sale|Zirconia beads price

- Wet Bead Mill|Bead Mill For Sale

- Sand Mill Machine|Sand Mill For Paint

- Sand Mill|Wet Grinding Equipment Manufacturer

- Bead Mill Machine

- Vertical sand mill

- Bead mill for paint

- Horizontal sand mill

- Turbine bead mill

- Lab bead mill

- Nano Mill

- Vertical Bead Mill

- Bag Filter

- Zirconia Beads

- Pearl Mill

- Dyno mills

- Horizontal Bead Mill

- Agitator bead mill

- Sand Mill

-

Three Roll Mill

-

Twin Shaft Disperser

-

High Speed Disperser

-

Basket Mill

-

High Shear Mixer

-

Double Planetary Mixer

-

Chemical Reactor

-

Kneader

-

Filling Machine

-

Multi-Shaft Mixer

-

Attritor Mill

-

Ribbon Blender

-

Pneumatic Mixer

-

Static Mixer

-

Nitrogen Generator

-

Production Line

- Tricks About Ointment Mill You Wish You ...

- A deep insight into Sand Mill Machine

- What is the difference between dyno mill...

- How To Choose Vertical Bead Mill or Hori...

- What is a three roll mill machine?

- Specification of high speed disperser an...

- Three Roll Mills: Their mechanism, advan...

- high speed disperser machine application

- Faults and Trouble Shooting Methods of H...

- How to operate High-Speed Disperser