-

Equipments

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Or Contact Info

-

Coating

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Adhesives

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Agrochemistry

-

-

Agrochemistry

- Emulsifiable Concentrate

- Suspension Concentrate

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Battery

-

-

Battery

- Battery Slurries

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Cosmetic

-

-

Cosmetic

- Lipstick

- Eyebrow Pencil

- Ointment

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

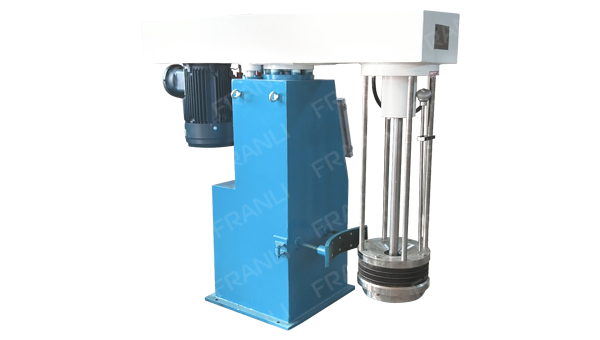

Basket Mill

FLE is the manufacturer of basket mills, we developed a new technology based on the traditional type of basket mill.

FLE is the manufacturer of basket mills, we developed a new technology based on the traditional type of basket mill.

FLE Basket Mill focuses on low energy, no hot spots, controlling constant temperature, higher production, the flexibility of batch size, and a wide range of product viscosities that can be processed well.

Hydraulic lifting of basket mill’s head, Motor with noise, and ventilator protection system. Which is designed with double basket jackets,dispersion disc, cooling inlet system, and material suction impeller.

Display of basket mill showing the product temperature, power input, operation time. You also can choose the automatic system of operation with the incorporation of all process parameters from the data bank.

The basket mill is widely used in many industries, including coating, ink, ceramics, pharmaceutical, and other production fields, including base, frame, main motor, grinding mechanism, and container. In the grinding basket of the grinding mechanism, a spiral wheel is set on the rotating shaft above the grinding blade, and a dispersing plate is used as the impeller. The dispersing plate is a disc with alternately upward or downward bending shear teeth, The disc body of the dispersion disc is provided with a diversion port and a diversion sheet; When working, the high-speed disperser first shears and disperses the materials, and the spiral wheel guides the materials into the grinding basket for grinding and dispersion. When the spiral wheel runs, more materials enter the grinding basket, which improves the grinding and dispersion efficiency. FLE basket mill not only shears and disperses materials, but also grinds and disperses materials. It has a simple structure and high efficiency.

The basket mill is a submersible milling unit that will achieve partial size reduction without the use of hear-to-clean pumps, hoses, and tanks. The basket mill allows a greater amount of material to pass through the milling chamber more open, resulting in a narrower particle size distribution and stronger pigment strength in a shorter amount of time.

The FLE basket mill is comprised of two shafts; The main shaft is the basket/media agitator shaft and the second is the batch agitator shaft. The media agitator shaft has a hub with several agitator pins; the pins agitator the media creating a rolling vortex within the basket. As the material falls into the basket through the opening in the top, it enters into the high-energy zone of the vortex and is pumped through the moving media in a radial flow.

As the product passed through the media it is ground by the slipping and rolling action of the media. The material then passes through the screen that separates the media from the batch and washes against the cooling shroud. This helps remove the heat build-up that was generated from the product passing through the milling chamber. The material is then passed down the side of the cooling shroud and back into the batch where it is an agitator and sent back through the milling chamber.

The batch agitator’s function is to assist in keeping the batch from sealing and to keep the material mixed while it is waiting for its next pass through the milling chamber. The FLE mixers mill is complete with controls for the mill agitator, comprising of a tachometer, ammeter, and a jog push button with a start/stop/speed potentiometer dial for the batch agitator.

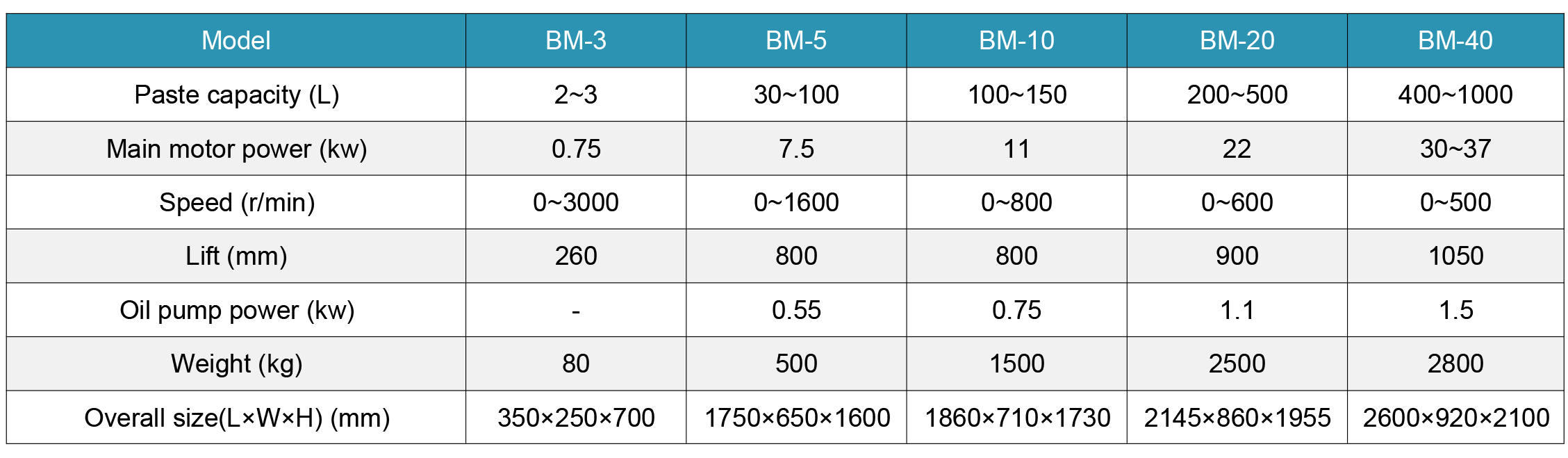

Main Technical Parameters

Application

Related Products

More

-

Vacuum Double Planetary Mixer

A Vacuum double planetary mixer is an essential part of any industry to mixing particular material. A double planetary m...

-

Laboratory Double Planetary Mixer

Laboratory double planetary mixer is a kind of non-standardized strong mixing and mixing equipment developed by FLE for ...

-

Hydraulic Lifting High Speed Disperser

The hydraulic lift high speed disperser has the characteristics of simple operation and high flexibility.The hydraulic l...

-

SMP Agitator bead mill

This SMP Agitator bead mill is used in the paint, ink, and coating industries to ready the equal-sized particles of a pa...

-

TRS-Three Roll Mill For Lipstick

TRS Three roll mill is widely used in milling paste material including paint, inks, China ink, pigment, coatings, food, ...

-

Basket Mill Machine

What is a FLE Basket Mill? Our basket mill combines dispersing and grinding into a single machine that is suitable for g...

News

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

Bead Mill

- SMP Agitator bead mill

- Zirconia beads for sale|Zirconia beads price

- Wet Bead Mill|Bead Mill For Sale

- Sand Mill Machine|Sand Mill For Paint

- Sand Mill|Wet Grinding Equipment Manufacturer

- Bead Mill Machine

- Vertical sand mill

- Bead mill for paint

- Horizontal sand mill

- Turbine bead mill

- Lab bead mill

- Nano Mill

- Vertical Bead Mill

- Bag Filter

- Zirconia Beads

- Pearl Mill

- Dyno mills

- Horizontal Bead Mill

- Agitator bead mill

- Sand Mill

-

Three Roll Mill

-

Twin Shaft Disperser

-

High Speed Disperser

-

Basket Mill

-

High Shear Mixer

-

Double Planetary Mixer

-

Chemical Reactor

-

Kneader

-

Filling Machine

-

Multi-Shaft Mixer

-

Attritor Mill

-

Ribbon Blender

-

Pneumatic Mixer

-

Static Mixer

-

Nitrogen Generator

-

Production Line

- Tricks About Ointment Mill You Wish You ...

- A deep insight into Sand Mill Machine

- What is the difference between dyno mill...

- How To Choose Vertical Bead Mill or Hori...

- What is a three roll mill machine?

- Specification of high speed disperser an...

- Three Roll Mills: Their mechanism, advan...

- high speed disperser machine application

- Faults and Trouble Shooting Methods of H...

- How to operate High-Speed Disperser