-

Equipments

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Or Contact Info

-

Coating

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Adhesives

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Agrochemistry

-

-

Agrochemistry

- Emulsifiable Concentrate

- Suspension Concentrate

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Battery

-

-

Battery

- Battery Slurries

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Cosmetic

-

-

Cosmetic

- Lipstick

- Eyebrow Pencil

- Ointment

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Basket Mill

-

Basket Mill Machine

What is a FLE Basket Mill? Our basket mill combines dispersing and grinding into a single machine th...

-

Basket Mill With Mixer

Basket mill with mixer is an indispensable equipment in coatings, ink, cosmetics, and other industri...

-

Lab Basket Mill

The lab basket mill is a common equipment for small-scale experiments and scientific research. Suita...

-

Basket Mill

FLE Basket Mill focuses on low energy, no hot spots, controlling constant temperature, higher produc...

FLE is the manufacturer of basket mill, we developed a new technology based on the traditional type of basket mill.

FLE Basket Mill focuses on low energy, no hot spots, controlling constant temperature, higher production, the flexibility of batch size, and a wide range of product viscosities that can be processed well.

Basket Mill

Hydraulic lifting of basket mill’s head, Motor with noise, and ventilator protection system. Which is designed with double basket jackets,dispersion disc, cooling inlet system, and material suction impeller.

Display of basket mill showing the product temperature, power input, operation time. You also can choose the automatic system of operation with the incorporation of all process parameters from the data bank.

Lab Basket Mill

Lab Basket Mill

Advantages of basket mill

l Grinding basket ensures well feeding material

l Cleaning or changing products are easy operations

l Control the dispersion and milling speed by ABB VFD

l Vacuum features to be operational by different material

Basket mill with mixer

Double jacket Basket

Double jacket for better cooling, special design of upper bracket ensure the beads cycling milling in the basket.

Basket

Different sizes of basket mesh for different materials and beads.

Working process

Cycling moving material by dispersing, milling in the basket

Pins on Basket Mill

Hardness Alloy of Pinto milling beads to get fine material in basket.

We are the basket mill and dispersion mill supplier. basket mill with a grinding bead in the mill base, the fast circulation of the milling within the milling basket is generated by the dissolver disc and integrated pump wheel to grinding material, the narrow particle size distribution can be quickly achieved.

If you choose basket mill, you will find lots of characteristics. Suitable for producing the small-batch product and middle test. Easily cleaning for your worker, no residues, convenient to replace productions to improve efficiency. Grinding by Little grinding media get Excellent grinding efficiency and effect. Double-jacketed for cooling and heating tank of basket mill. The mixing disc ensures an even product circulation to process products with a large range of viscosities.

For optimum and efficient control of the product temperature, the processing tank, and the grinding basket cover are in double-walled and temperature-controlled execution.

The operating speeds for milling and dispersion can be adjusted either manually or via an automatic control system.

If you have a small batch size, which will be more high flexibility.

Production Line

-

PCB INK Machine line

FLE supplies all equipments for the production of PCB inks, from the powder feeding station to the filling part.

-

Offset Ink, UV Ink machine line

The FLE engineering company, offer the full set of UV INK Production Line, we can make the full drawing according with your factory size, fo...

-

Offset Ink machine line

FLE is specialized in offset ink full line production for 20+ years. Helped customer save the cost, save the man power, also save the space....

Equipments

News

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

Bead Mill

- SMP Agitator bead mill

- Zirconia beads for sale|Zirconia beads price

- Wet Bead Mill|Bead Mill For Sale

- Sand Mill Machine|Sand Mill For Paint

- Sand Mill|Wet Grinding Equipment Manufacturer

- Bead Mill Machine

- Vertical sand mill

- Bead mill for paint

- Horizontal sand mill

- Turbine bead mill

- Lab bead mill

- Nano Mill

- Vertical Bead Mill

- Bag Filter

- Zirconia Beads

- Pearl Mill

- Dyno mills

- Horizontal Bead Mill

- Agitator bead mill

- Sand Mill

-

Three Roll Mill

-

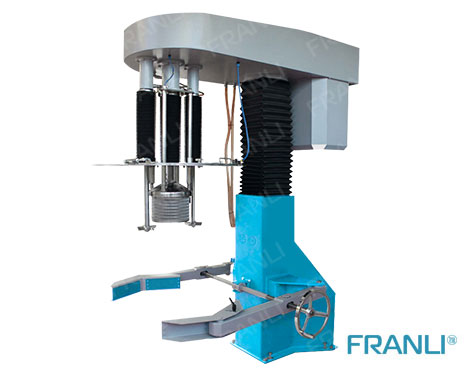

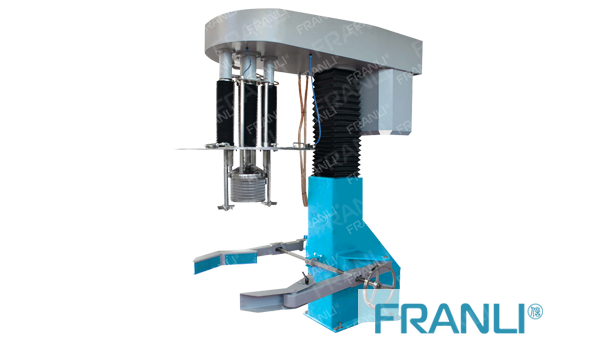

Twin Shaft Disperser

-

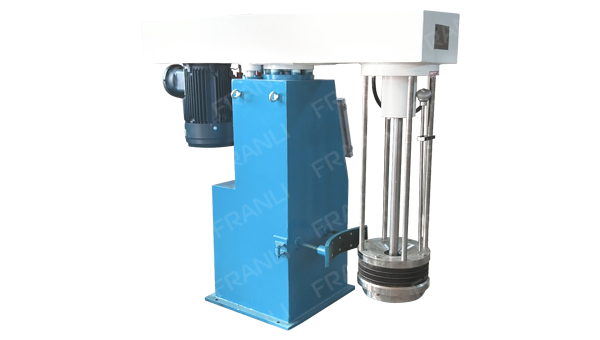

High Speed Disperser

-

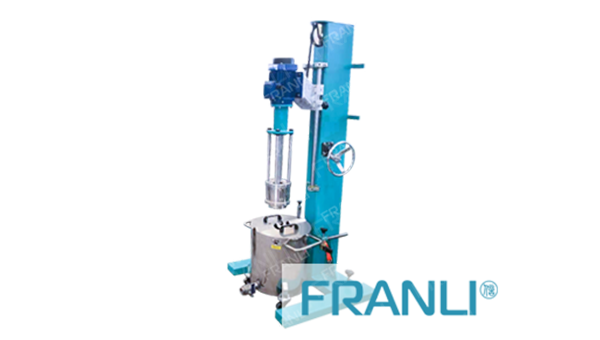

Basket Mill

-

High Shear Mixer

-

Double Planetary Mixer

-

Chemical Reactor

-

Kneader

-

Filling Machine

-

Multi-Shaft Mixer

-

Attritor Mill

-

Ribbon Blender

-

Pneumatic Mixer

-

Static Mixer

-

Nitrogen Generator

-

Production Line

- Tricks About Ointment Mill You Wish You ...

- A deep insight into Sand Mill Machine

- What is the difference between dyno mill...

- How To Choose Vertical Bead Mill or Hori...

- What is a three roll mill machine?

- Specification of high speed disperser an...

- Three Roll Mills: Their mechanism, advan...

- high speed disperser machine application

- Faults and Trouble Shooting Methods of H...

- How to operate High-Speed Disperser