-

Equipments

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Or Contact Info

-

Coating

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Adhesives

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Agrochemistry

-

-

Agrochemistry

- Emulsifiable Concentrate

- Suspension Concentrate

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Battery

-

-

Battery

- Battery Slurries

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

-

Cosmetic

-

-

Cosmetic

- Lipstick

- Eyebrow Pencil

- Ointment

-

-

-

NEWS

- Double planetary mixer new t...

- Multiple paddle options of D...

- Double planetary mixer is th...

- Multiple mixing tanks with d...

- Double planetary mixer for c...

- Double planetary mixer can b...

- Double planetary mixer has E...

- Double Planetary Mixer Excel...

- Principle of asteroid rotati...

- Efficient and uniform mixing...

-

Contact Us

Attritor Mill

Attritor mill indicates the medium-range grinding machine where particles dissolved in the fluid; after that, the paddles of the machine pull it over perfectly, and they are grounded with collisions with each other or converted into a medium grind.

Attritor mill indicates the medium-range grinding machine where particles dissolved in the fluid; after that, the paddles of the machine pull it over perfectly, and they are grounded with collisions with each other or converted into a medium grind.

This is a great machine in which you can reduce or disperse extra-sized particles, and this method is done by the strong movement of the slurry of the alloy.

If you continue milling for 10 hours, you will get a particular 40 surface, and alumina and barite will preserve 25 m²/g and related to 38 and 56 nm similar round diameter, individually.

Key Features of Attritor Mill

You may find lots of Attritor Mill in different sizes in the market. But the special thing is that every size is fit for the wet or dry grinding process. At this stage, we want to clear up every key feature that makes Attritor Mill the ultimate champion.

Metal-Based Contamination Free Machine

Designed With Variable Speed

Easy Startup

Larger In SIze

Tanks Covered For Cooling And Heating

Equipped With Torque Meter

Suitable To Any Atmosphere

Metal-Based Contamination Free Machine

The Attritor mill is a great example of a metal-based contamination-free machine. It is specially designed for the ceramic industry. Inside the interior of the machines, you can find a variety of ceramic and polymer materials to line or sleeve from around. Silicon Carbide, Alumina, Silicon Nitride, Rubber, Tungsten Carbide, Polyurethane, Zirconia, and many more plastics are included in those materials.

Designed With Variable Speed

The mill is especially known for its tremendous speed. The Laboratory-based Attritor mill can produce an extreme level of RPM for various purposes. Attritor mills grinding tank varies in size; you can get up to 100 ml to 9 and a half Liters following your service.

Easy Startup

Production-based attritors are equipped with a giant torque motor of 450%, and the starting time of this huge torque motor is easy and lightning fast. The motor comes with two different speed dividers. The power-speed dialer is reserved for the original grinding, and the bottom one is used for basic charging or discharging and washing purposes.

Larger In SIze

Attritor mill is more convenient for mid-range size particles. The mill has a wider size in distribution, including the largest particle size of 35 μm.

Tanks Covered For Cooling And Heating

One of the attractive key features of the attritor mill is that all its grinding tanks are covered with adjustable temperatures. So, the user can use the grinder tank for the cooling and heating process.

Equipped With Torque Meter

A torque meter is pre-installed so that you can measure the energy limitation. This way the user can calculate and save energy from the total power consumption. Using this technology, anyone can control the whole grinding process.

Suitable To Any Atmosphere

Adjusting to the atmosphere is a must in any kind of mill grind. Considering this major fact, the Attritor mill comes with the latest technology; you can place the machine in any suitable place.

Why Should You Choose an Attritor Mill?

By going through all the topics, we guess you might get all the required information. The attritor mill comes with a stain steel metal body feature; this unique body makes it different from others in this competitive market.

Rather than that, The attritor has a special capability to work under a range of terms and conditions. Besides that, the Attritor mill can make the highest strength intimate blending as well.

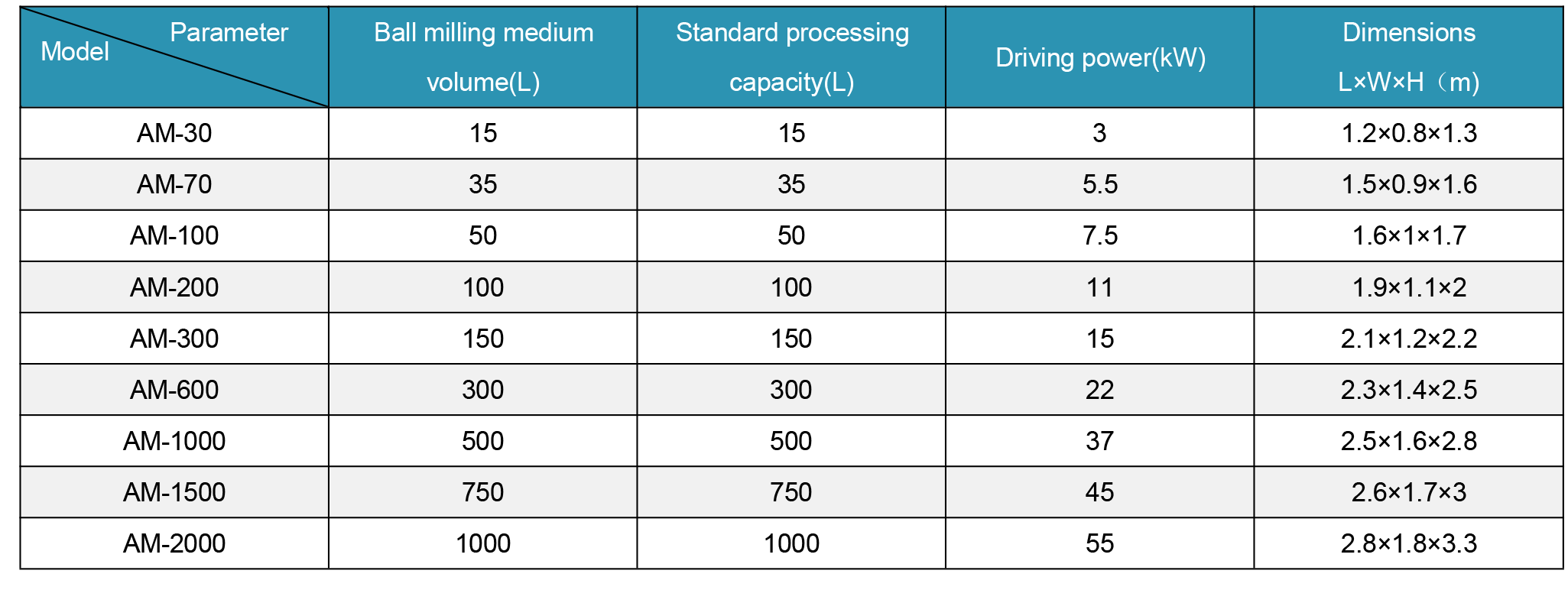

Main Technical Parameters

Application

Related Products

More

-

Vacuum Double Planetary Mixer

A Vacuum double planetary mixer is an essential part of any industry to mixing particular material. A double planetary m...

-

Laboratory Double Planetary Mixer

Laboratory double planetary mixer is a kind of non-standardized strong mixing and mixing equipment developed by FLE for ...

-

Hydraulic Lifting High Speed Disperser

The hydraulic lift high speed disperser has the characteristics of simple operation and high flexibility.The hydraulic l...

-

SMP Agitator bead mill

This SMP Agitator bead mill is used in the paint, ink, and coating industries to ready the equal-sized particles of a pa...

-

TRS-Three Roll Mill For Lipstick

TRS Three roll mill is widely used in milling paste material including paint, inks, China ink, pigment, coatings, food, ...

-

Basket Mill Machine

What is a FLE Basket Mill? Our basket mill combines dispersing and grinding into a single machine that is suitable for g...

News

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

28

2023-04

-

Bead Mill

- SMP Agitator bead mill

- Zirconia beads for sale|Zirconia beads price

- Wet Bead Mill|Bead Mill For Sale

- Sand Mill Machine|Sand Mill For Paint

- Sand Mill|Wet Grinding Equipment Manufacturer

- Bead Mill Machine

- Vertical sand mill

- Bead mill for paint

- Horizontal sand mill

- Turbine bead mill

- Lab bead mill

- Nano Mill

- Vertical Bead Mill

- Bag Filter

- Zirconia Beads

- Pearl Mill

- Dyno mills

- Horizontal Bead Mill

- Agitator bead mill

- Sand Mill

-

Three Roll Mill

-

Twin Shaft Disperser

-

High Speed Disperser

-

Basket Mill

-

High Shear Mixer

-

Double Planetary Mixer

-

Chemical Reactor

-

Kneader

-

Filling Machine

-

Multi-Shaft Mixer

-

Attritor Mill

-

Ribbon Blender

-

Pneumatic Mixer

-

Static Mixer

-

Nitrogen Generator

-

Production Line

- Tricks About Ointment Mill You Wish You ...

- A deep insight into Sand Mill Machine

- What is the difference between dyno mill...

- How To Choose Vertical Bead Mill or Hori...

- What is a three roll mill machine?

- Specification of high speed disperser an...

- Three Roll Mills: Their mechanism, advan...

- high speed disperser machine application

- Faults and Trouble Shooting Methods of H...

- How to operate High-Speed Disperser